A caution, A warning, Table 16—wet coil pressure drop – Carrier 48N User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

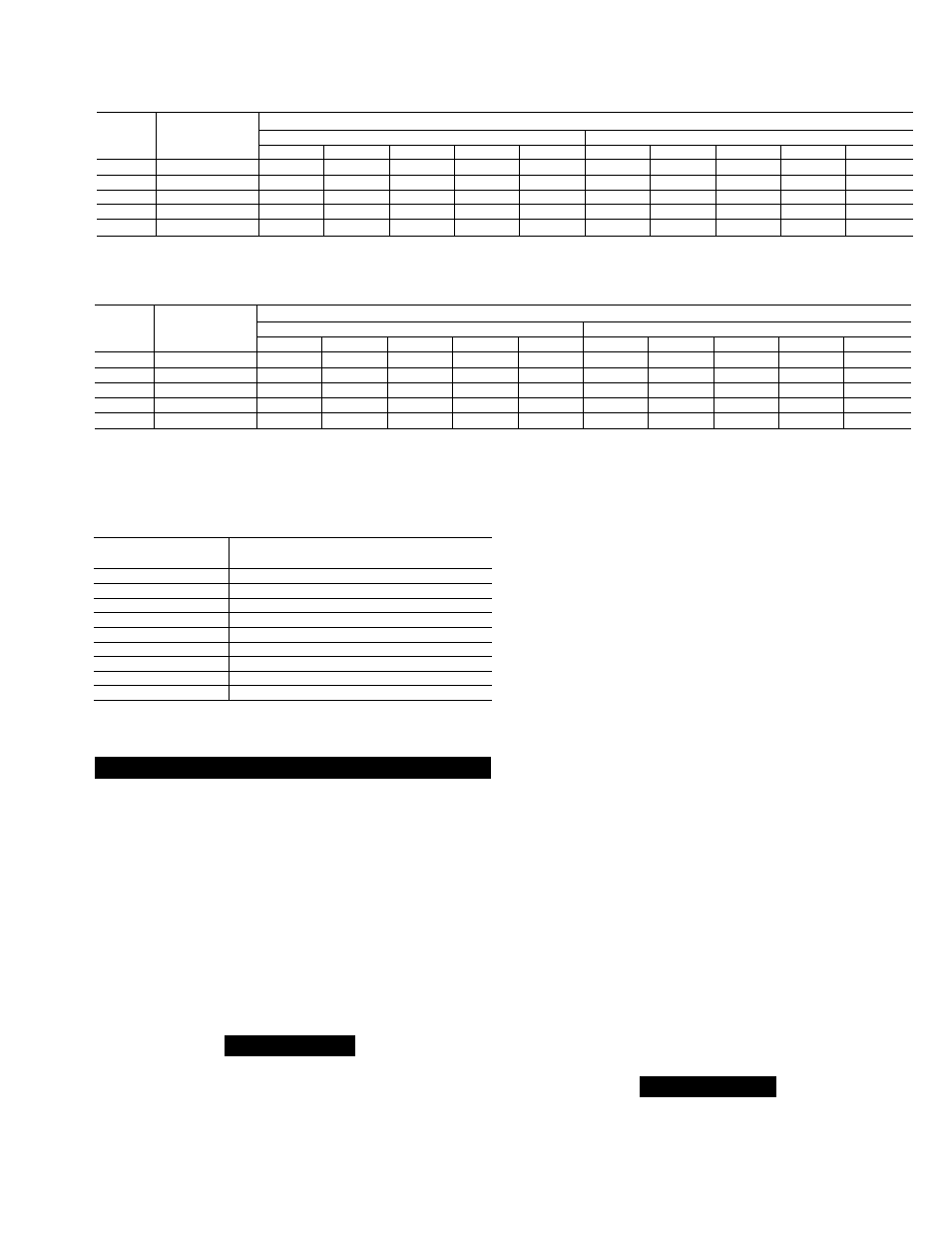

Table 14—Model 48NT060 (Belt Drive) Air Delivery (Cfm) At Indicated External

Static Pressure (in. W.C.) (Dry Coil without Air Filter*)

End Discharge

EXTERNAL STATIC PRESSURE—INCHES WATER

PULLEY TURNS

208V

230V or 460V

RPM

OPEN

0.0

0.2

0.4

0.6

0.8

0.0

0.2

0.4

0.6

0.8

1430

1 See Note #2

2761

2534

2343

2152

1965

2808

2588

2331

2189

2007

1380

2

2685

2444

2230

2035

1829

2716

2498

2282

2075

1864

1330

3

2583

2341

2129

1921

_

2585

2355

2154

1921

—

1280

4

2445

2174

1960

—

—

2454

2209

1966

1733

—

1230

5

2287

1964

1775

—

—

2287

2028

1780

—

—

Table 15—Model 48NT060 (Belt Drive) Air Delivery (Cfm) At Indicated External

Static Pressure (in. W.C.) (Dry Coil without Air Filter*)

Down Discharge

EXTERNAL STATIC PRESSURE—INCHES WATER

PULLEY TURNS

208V

230V or 460V

RPM

OPEN

0.0

0.2

0.4

0.6

0.8

0.0

0.2

0.4

0.6

0.8

1430

1 See Note #2

2623

2407

2225

2044

1867

2667

2458

2243

2078

1906

1380

2

2551

2322

2118

1933

1737

2580

2373

2168

1971

1771

1330

3

2454

2221

2022

1825

—

2465

2237

2046

1825

—

1280

4

2323

2065

1862

—

—

2331

2098

1867

—

—

1230

5

2272

1866

—

—

—

2173

1927

—

—

—

NOTES: 1. Factory setting is 4 turns open.

2. Do not operate biower beiow 1 turn open on motor puiiey. Motor overheating may resuit.

3. Do not operate unit in cooiing mode at airfiow rate beiow 1750 cfm. Indoor coii icing may occur.

’Air delivery values are without air filter. Air delivery values are for dry coil. See Table 16, page 10 for coil pressure drop. Deduct field supplied filter pressure

drop and wet coil pressure drop to obtain external static pressure available for ducting.

Table 16—Wet Coil Pressure Drop

Airflow

(CFM)

Pressure Drop

(in.

W.C.)

650

0.038

850

0.046

1050

0.066

1250

0.081

1450

0.111

1650

0.129

1850

0.150

2050

0.180

2250

0.198

A. Air Filter

A CAUTION

Never operate the unit without a suitable air filter in

the return-air duct system. Always replace the filter

with the same dimensional size and type as originally

installed. See Tables 2 thru 7 for recommended filter

sizes.

Inspect air filter(s) at least once each month and replace

(disposable-type) or clean (cleanable-type) at least twice dur

ing each heating and cooling season or whenever the filter(s)

becomes clogged with dust and lint.

Replace filters with the seune dimensional size and type as

originally provided, when necessary.

B. Unit Top Removal

A CAUTION

Condenser fan and motor are fastened to the unit top.

When removing the top, use extreme care to not puU

the fan motor leads loose.

NOTE:

When performing maintenance or service procedures

that require removal of the unit top, be sure to perform all

of the routine maintenance procedures that require top

removal, including: inspection of the heat exchanger area,

coil inspection and cleaning, emd condensate drain pan

inspection and cleaning.

Only qualified service personnel should perform mainte

nance and service procedures that require unit top removal.

Refer to the following top removal procedures:

1. Turn off gas supply, then turn off electric power to

unit.

2. Remove all screws that secure unit top, including

screws euound four sides and those on top that screw

into internal divider panels. Save all screws.

3. Tape all side panels at each seam near unit top. Use

tape strips that are at least 5-ins. long to prevent sides

from falling when top is removed.

4. Lift top from unit carefully. Set top on edge and ensure

that top is supported by unit side that is opposite duct

(or plenum) side. Use extreme care to prevent damage

to the fan blades, motor, and insulation.

5. Carefully replace and secure unit top to unit, using

screws removed in step 3, when maintenance and/or

service procedures are concluded. (Be sure to use origi

nal screws that have rubber washers to seal out water

when securing top to internal divider panels.)

C. Evaporator Blower and Motor

For longer life, operating economy, and continuing efl&-

ciency; clean accumulated dirt and grease from the blower

wheel and motor annually.

Lubricate the motor every 5 years if the motor is used inter

mittently (thermostat FAN switch in AUTO position), or

every 2 yeeus if the motor is used continuously (thermostat

FAN switch in ON position).

A WARNING

Turn off the gas supply, then disconnect and tag electri

cal power to the unit before cleaning and lubricating the

blower motor and wheel. Failure to adhere to this warn

ing could cause personal injury or death.

17