I. refrigerant circuit, J. gas input, K. evaporator airflow – Carrier 48N User Manual

Page 22: L. metering device servicing, M. liquid line strainer

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

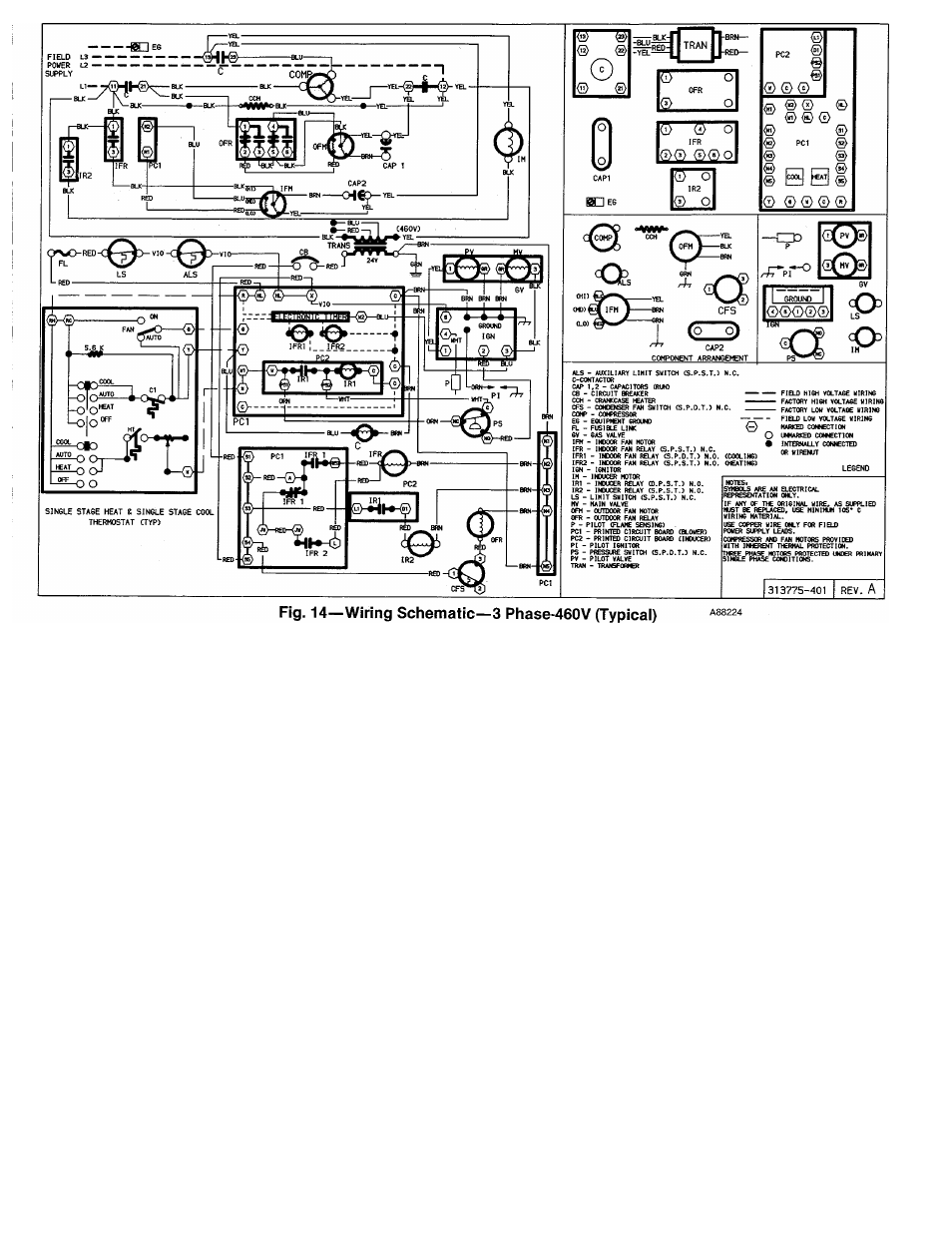

occurred, check each electrical component with the proper

electrical instrumentation. Refer to the unit wiring label

when making these checkouts.

NOTE:

Refer to the heating and/or cooling sequence of oper

ation in this publication as an aid in determining proper con

trol operation.

I. Refrigerant Circuit

Inspect all refrigerant tubing connections and the unit base

for oil accumulations annually. Detecting oil generally indi

cates a refrigerant leak.

If oil is detected or if low cooUng performance is suspected,

leak-test all refrigerant tubing; using an electronic leak-

detector, halide torch, or liquid-soap solution. If a refriger

ant leak is detected, see Step 7, part B, “Refrigerant

Leaks,” in this publication.

If no refrigerant leaks are found and low cooling perform

ance is suspected, see Step 9, part B, “Checking and

Adjusting Refrigerant Charge,” in this pubhcation.

J. Gas Input

The gas input does not require checking unless improper

heating performance is suspected. If a problem exists, refer

to Step 8 of this publication.

K. Evaporator Airflow

The heating and/or cooling airflow does not require checking

unless improper performance is suspected. If a problem

exists, be sure that all supply- and return-air grilles are open

and free from obstructions, and that the air filter is clean.

When necessary, refer to Step 9, part C, of this pubhcation

to check the system airflow.

L. Metering Device Servicing

See Fig. 15 for metering device components. The piston has

a refrigerant metering orifice through it. The retainer forms

a seahng surface for hquid hne flare connection. To check,

clean or replace piston:

1. Shut off power to unit.

2. Remove refrigerant from unit using approved refriger

ant removed methods.

3. Remove hquid line flare connections from metering

device.

4. Note position of arrow on metering device body with

respect to unit.

5. PuU retainer out of body. Be careful not to scratch flare

seahng surface. If retainer does not puU out easily,

carefuhy use locking phers to remove retainer. Replace

scratched or damaged retainer.

6. Slide piston out by inserting a smah soft wire through

metering hole (18-gage thermostat wire). See that

metering hole, seahng surface around piston cones and

fluted portion of piston are not damaged.

7. Chart on unit access panel ihustrates proper arrange

ment and size of piston. See Table 17 for piston sizes.

8. Clean piston refrigerant metering orifice.

9. Replace reteuner 0-riug Part No. is 99CC501052.

M. Liquid Line Strainer

The Liquid Line Strainer (to protect metering device), is

made of wire mesh and located in the hquid hne on inlet

side. Strainer is pressed into the hne. Remove strainer by

threading a No. 10 sheet metal screw into strainer and puU-

ing the screw with phers.

22