Carrier 5H User Manual

5f,h, Compressors and condensing units, Installation instructloos

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Carrier

installation instructloos^

5F,H

Compressors and Condensing Units

O p e n , W a t e r - C o o l e d

COMPRESSOR AND CONDENSING UNIT PHYSICAL DATA

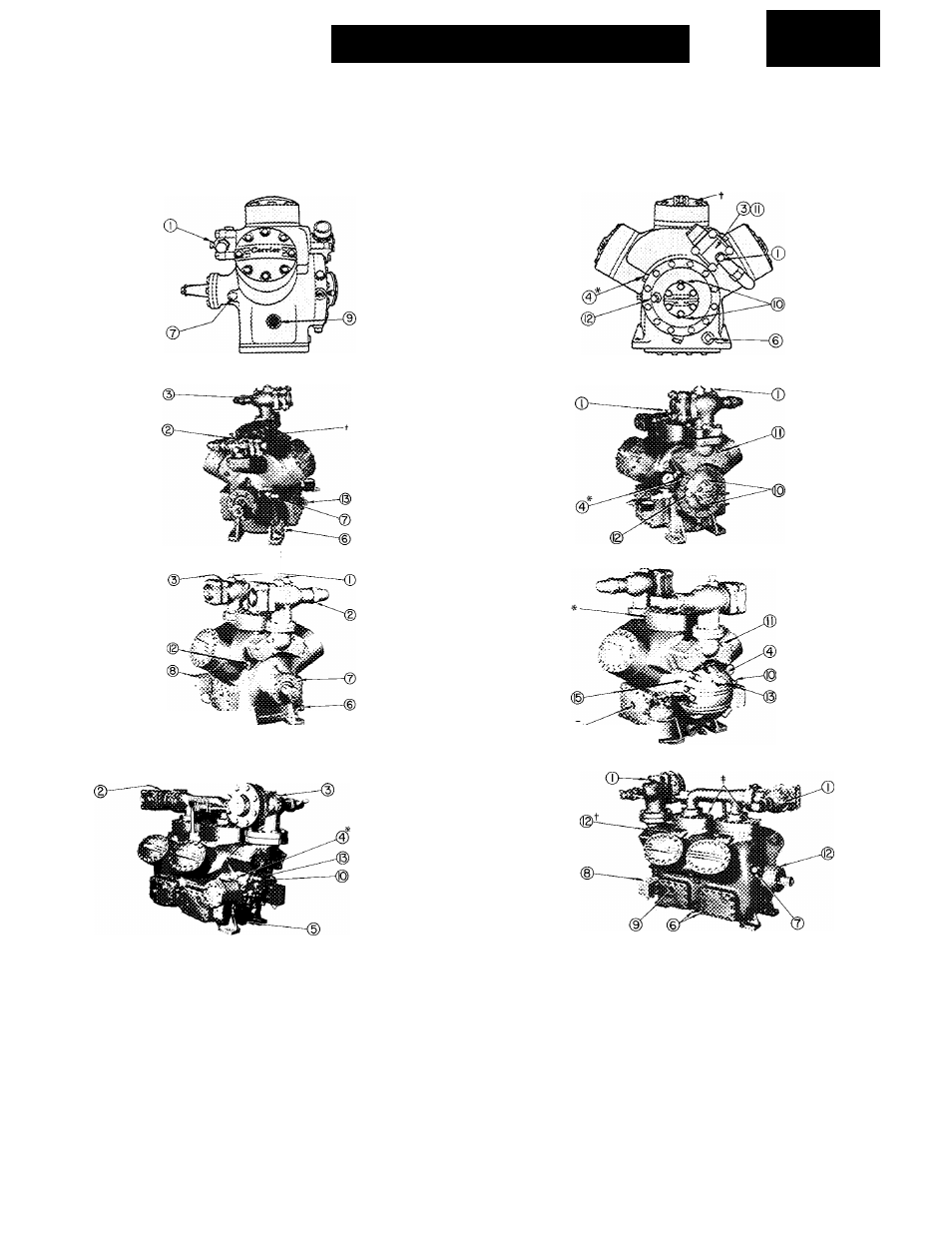

*A!so used for low pressure oil line

connection.

¡This bank of cylinderson 5F30 only

Fig. 1 - 5F20, 2-Cyl and 5F30, 3-Cyl Compressors

*Also used for low pressure oil line

connection.

IThis bank of cyl inders on 5F60 only.

Fig. 2 - 5F40, 4-Cyl and 5F60, 6-Cyl Compressors

*This bank of cylinders on 5H60 and

66 only.

@r

Fig. 3 - 5H40, 46, 4-Cyl and 5H60, 66, 6-Cyl Compressors

*Also used for lo^ pressure oil line

connection on 5Hl20 and 126.

["SHSO and 86 only.

IThese banks of cylinders on 5H120

and 126 only.

Fig. 4 - 5H80, 86, 8-Cyl and 5H120, 126, 12-Cyl Compressors

COMPRESSOR KEY

Gage connection 1/4-inch IPS.

(2) Discharge shut-off valve. (See Physical Data for size.)

Suet ion shut-off valve. (See Physical Data for size.)

Oil fi Iler plug

Crankcase drain (5/8-inch -18 plug on all 5F compressors,

shut-off valve on all 5H compressors)

Crankcase heater casing

© Oil pressure regulator

Dual pressurestat.

Oil level sight glass

Oil pump rotation arrows

(iT) Suction valve, manifold or manifold cover. Remove for access

to suction strainer.

Oil pressure connection 1/4-Inch IPS (high pressure).

Capacity control adjustment.

@ Oil Filter

(l^y Oil pressure connection 1/4-inch IPS (low pressure).

© Carrier Corporation 1968

5F,H-1SI

Document Outline

- Open, Water-Cooled

- COMPRESSOR AND CONDENSING UNIT PHYSICAL DATA

- Fig. 1 - 5F20, 2-Cyl and 5F30, 3-Cyl Compressors

- Fig. 2 - 5F40, 4-Cyl and 5F60, 6-Cyl Compressors

- Fig. 3 - 5H40, 46, 4-Cyl and 5H60, 66, 6-Cyl Compressors

- Fig. 4 - 5H80, 86, 8-Cyl and 5H120, 126, 12-Cyl Compressors

- COMPRESSOR KEY

- INSPECT SITE

- Machine Room Temperature and Ventilation -

- PREPARE FOUNDATION

- INSPECT UNIT

- COMPRESSOR INSTALLATION

- Compressor on Steel Base and Support Stand -

- Compressor Bolted to Concrete Base - See Fig. 8.

- Fig. 11 - Wiring Schematic Single Pumpout Cycle

- Table 10 - 5F,H Compressor Crankcase Heater Package

- Table 11 - Crankcase Heater Relay (60-Cycle)

- COMPRESSOR OPERATION

- íttiíítedxaTeíy aíter ¿starting: cort^eascr.

- Fig, 12 - Correct Belt Alignment

- REFRIGERANT PIPING

- CONDENSER WATER PIPING

- LUBRICATION

- REFRIGERANT CHARGING