Machine room temperature and ventilation, Prepare foundation, Inspect unit – Carrier 5H User Manual

Page 4: Compressor installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Machine Room Temperature and Ventilation -

Locate compressor or condensing unit in well

ventilated space. Check code requirements. Pro

vide forced ventilation thru ductwork when natural

ventilation is inadequate.

Protect

water-cooled

condensers,

water

lines,

and

accessories

from

freezing

during

winter

shutdown periods.

PREPARE FOUNDATION

Fasten compressor to: (a) steel base and vibra

tion isolators on floor; (b) steel base and condenser

support stand or (c) concrete base.

Floor

Foundations

-

Locate

compressors

over

joists or beams wherever possible.

Weak floors in old buildings must be reinforced

with steel beams or timbers to support the heavy

compressors

or

condensing

units.

Use

care

in

placing supports to avoid transmitting objection

able vibrations to other areas.

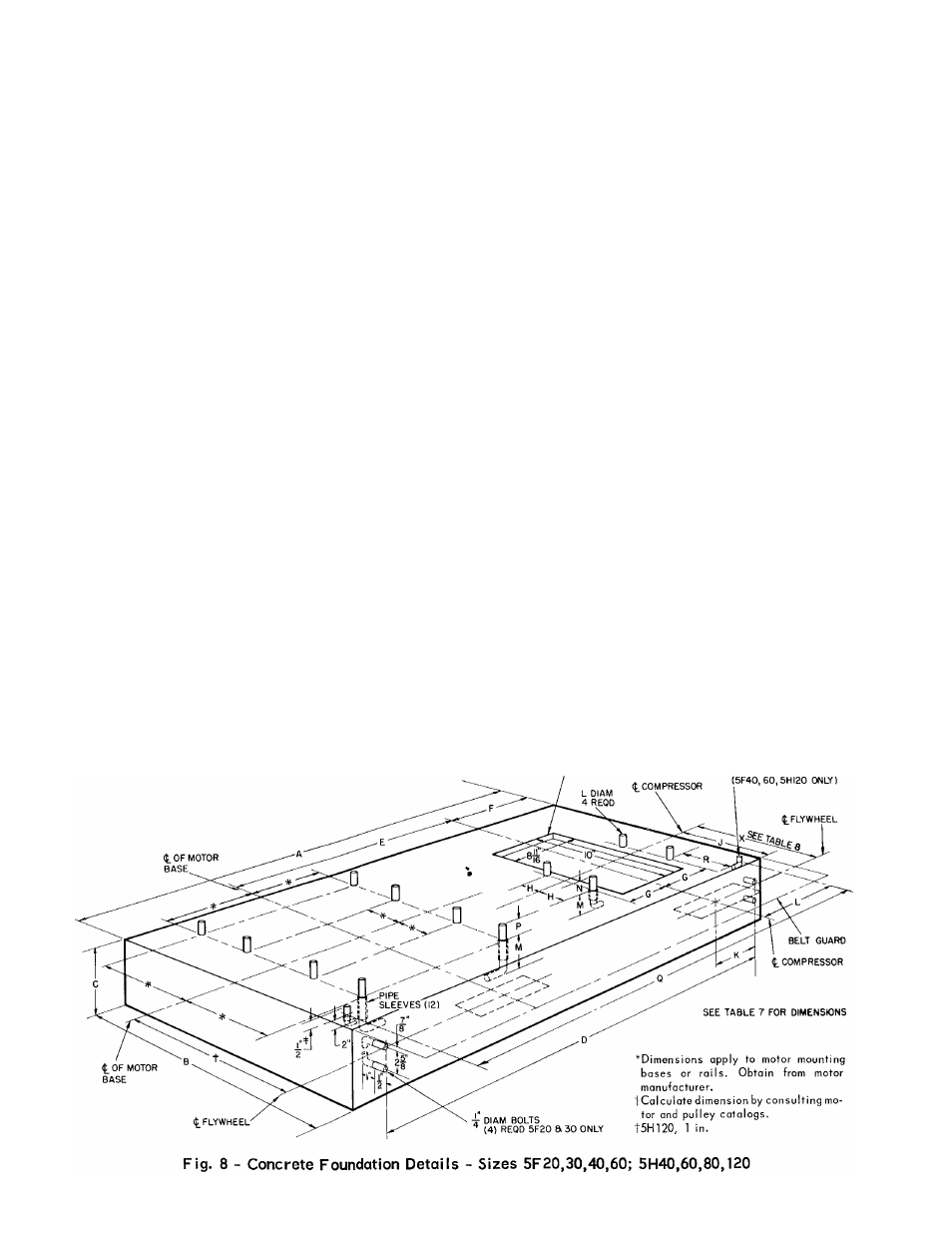

Concrete Foundations one to two times the weight

of the machinery they support will absorb vibra

tion. See Fig. 8 and Tables 7 and 8 for recom

mended dimensions. Let foundation set sufficiently

before

compressor

is

installed

(approximately

3

days). Allow for 3/8 inch to 1/2 inch grout after

compressor is installed.

Heavy

aggregate

concrete

weighs

about

150

pounds per cubic foot.

INSPECT UNIT

Inspect

shipment

for

damage

or

loss.

File

claim immediately with shipping company for any

loss or damage.

Move and rig unit carefully to prevent damage

to

gages,

mounting

brackets,

refrigerant

piping

and connections.

COMPRESSOR INSTALLATION

Compressor on Steel Base and Vibration Isolators

on Floor — Install vibration isolators on one end of

unit at a time. See Fig. 9 for typical vibration

isolator mounting.

Motor fastening set supplied with all com

pressors (except 5F20,30) includes several beveled

washers.

Washers

are

installed

under

heads

of

capscrews used to fasten unit base to vibration

isolators or floor.

Position compressor and motor on frame and

check height of vibration isolators. Shim between

vibration isolators and floor to level compressor

base Secure vibration isolators to floor. If beveled

washer (Fig. 9) is omitted, end of capscrew may

strike the floor and cause vibration isolator to

rupture when it is secured to floor.

Condenser and Stand Assembly - Place cast iron

condenser stands in their correct location. Make

distance ”C" (Fig. 10) between tapped holes on

top of stand equal to holes in lower flange of com

pressor unit base. See Table 9 for dimensions.

Shipping caps are soldered to the 5F20,30,40

and 60 condensers at the factory. To remove caps

turn condensers upside down. This prevents solder

from falling into condensers.

Bolt lower support strap loosely to lower side

of each condenser stand.

Place condenser on stands with front water

head at compressor end of base. Position con-

DEPRESSION FOR COMPRESSOR

BOTTOM PLATE 5F30 ONLY

CORNER BOLTS (2)

L

569