Carrier 5H User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Oil Filter should be replaced after 50 hours opera

tion and whenever oil is changed or becomes dirty.

Oil Separator (Optional) - Install separator so its

weight is carried by supports or hangers and not

piping.

Connect

separator

inlet

to

compressor

dis

charge and separator outlet to condenser. Con

nect oil return line (1/4-inch or 3/8-inch copper

tubing) between separator and compressor crank

case. Make line long enough to be flexible and free

from strain. Connect oil return line to upper oil

and gas equalizer line connection (if available) on

compressor. When two compressors are installed

in parallel, connect oil return line to oil equalizer

line between the two compressors. Install shut

off valve in oil return line to facilitate service and

minimize refrigerant loss.

An additional oil charge is required when an

oil separator is used. Watch oil level and check

separator

float

valve

operation

during

initial

compressor

operation.

Follow

instructions

fur

nished with oil separator.

Compressor Muffler (Optional) - Mufflers are in

cluded in condenser piping packages for all 5H

condensing

units.

They

are

recommended

for

all

remote

installations.

Install

mufflers

either

hori

zontally or vertically (refrigerant flow downward).

Arrow on muffler indicates flow direction. Place

outlet at bottom in horizontal installations to pre

vent trapping oil. Locate muffler as close as pos

sible to compressor.

Special Handhole Cover Plates (Optional) have

tapped holes for connecting equalizer lines. When

operating

compressors

in

parallel,

replace

stan

dard covers with special covers. See Fig. 13.

5H120 AND 126 - Tapped cover plate is standard

on 5H120 and 126 compressors. Use only lower

connection for oil equalization. Connect gas equal-

GAS EQUALIZER

■

CpiMNECTION

- j . .

|| OD FLANGE

--CC

Ì

OIL EQUALIZER

CONNECTION

I" IPS

.-.1 i

Fig. 14- Equalizer Connections

(5H120 and 126)

ization line at flange connection. See Fig. 14.

Mating flange for 1-1/8 inch OD is Mueler part

no. A-515; gasket no. A-5152.

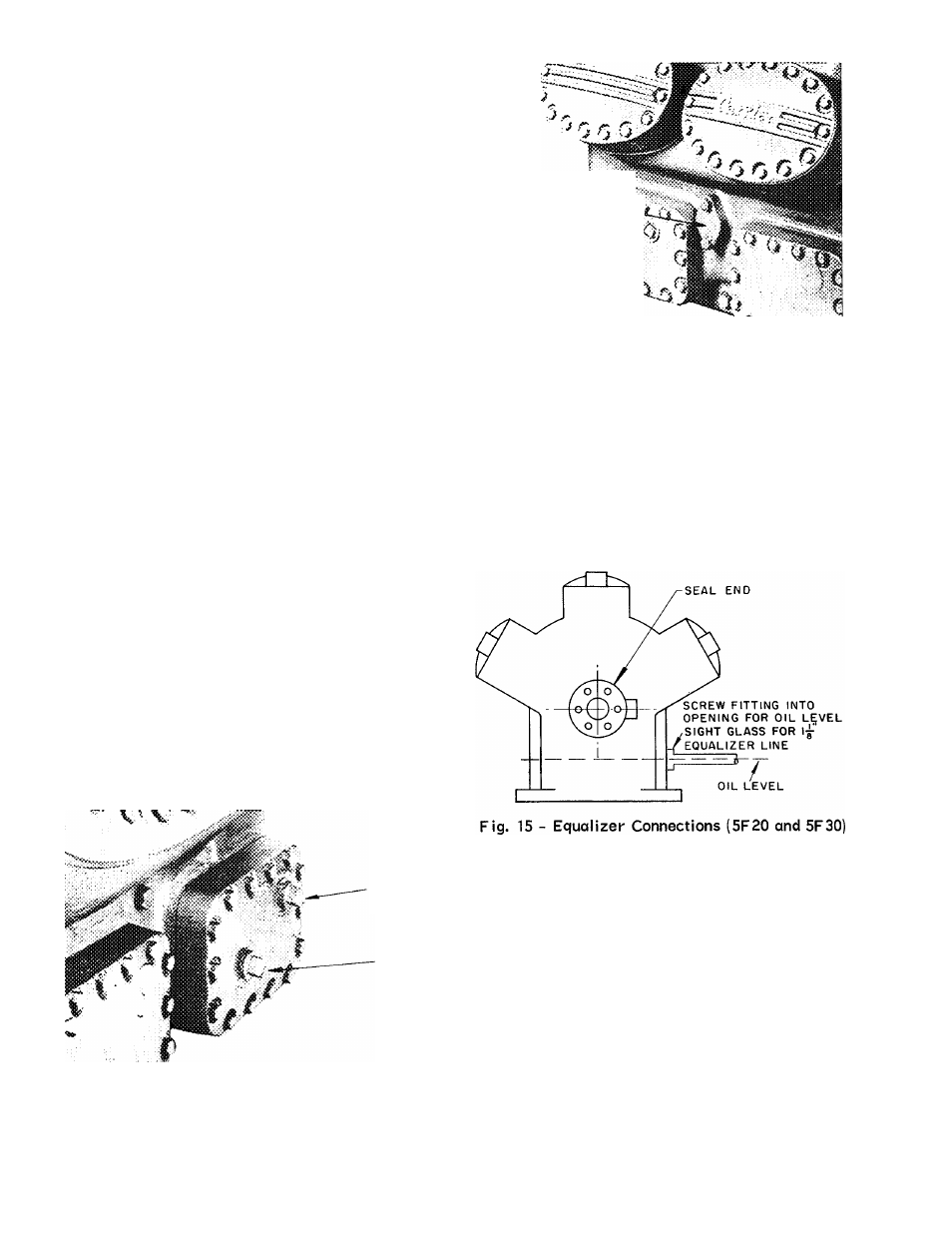

5F20 AND 30 compressors have no special tapped

cover plate. Use opening for oil sight glass with

1-1/8-inch line for gas and oil equalization. For

additional equalization, run a 3/8-inch line to oil

fill plug. See Fig. 15.

GAS

EQUALIZER

CONNECTION

OIL

EQUALIZER

CONNECTION

Fig. 13 - Special Handhole Cover

with Equalizer Connections

Cooled Heads - When used, install water-cooled

heads and piping as shown in Fig. 16.

5F20,30,40,60;

5H40,46,60,66,80

AND

86

com

pressors have one water circuit piped to flow in

either direction. See Fig. 16.

5H120 AND 126 compressors have two parallel

circuits with two 1/2-inch IPS water inlet con

nections and one 1/2-inch IPS water outlet con

nection. See Fig. 16.

Install manually operated valve in each water

circuit, adjusted for 100 F maximum leaving water

temperature.