Condenser water piping, Lubrication – Carrier 5H User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 12 - Compressor Oil Charge

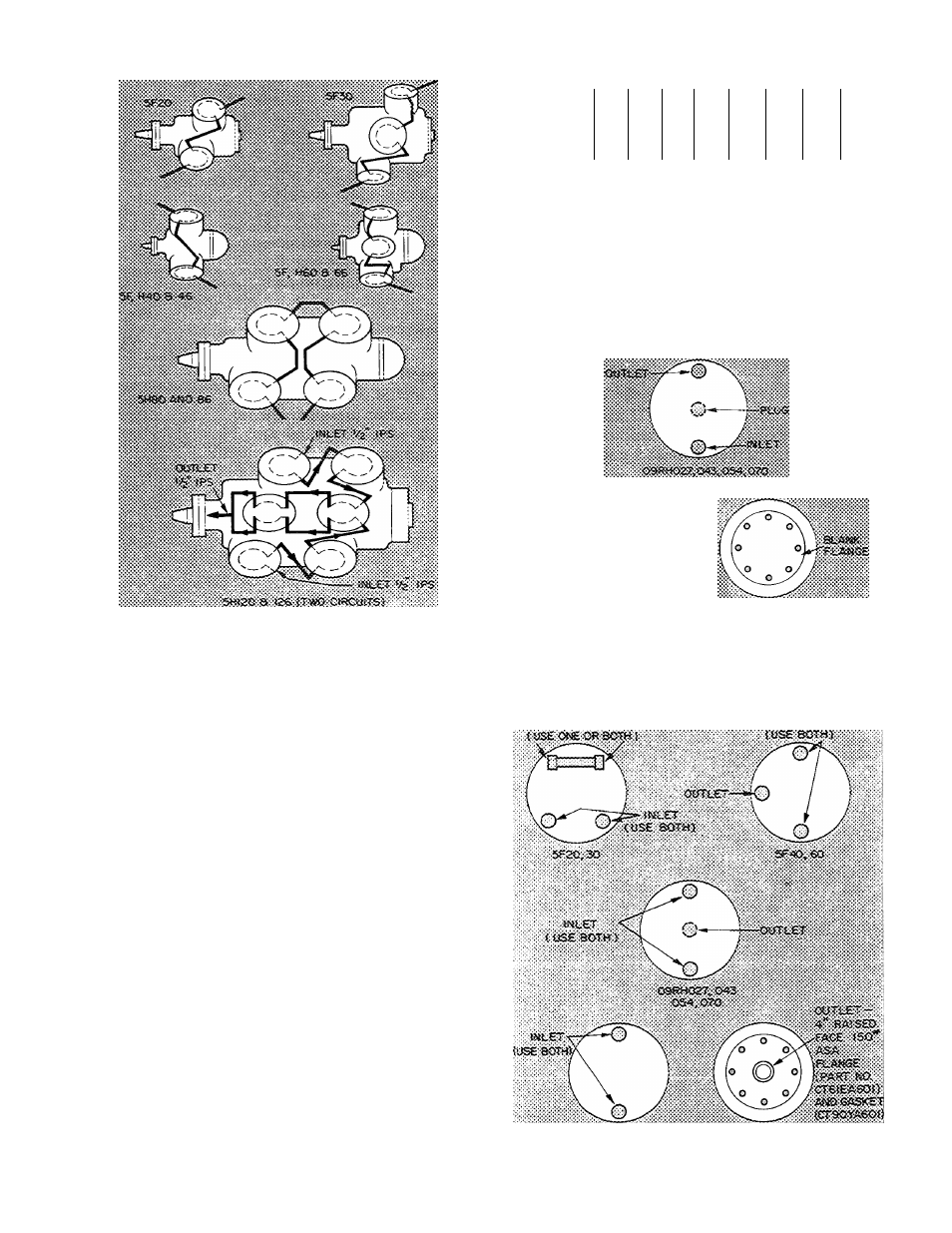

Fig. 16 - Schematic Piping for

Water-Cooled Heads

COMPRESSOR

5F20 5F30 5F40 5F60

5H40,

5H46

5H60,

5H66

5H80,

5H86

OIL CHG (pt)

5

5-1/2

12

13

18

21

41

erri mres

itec.

f '

Sr2e>aci

O'

5H120,

5H126

81

8UiS-^0

QiiilSA—y^ “~0

/

N

111

cîîifî>'0a>ii>e3?>Kï7

Fig. 17 - Condenser Maximum Pass Connections

CONDENSER WATER PIPING

Piping - Use piping for maximum pass operation,

Fig. 17, when ample water pressure is available.

Use minimum pass operation. Fig. 18, for low

water pressure or when cooling tower is used.

Water Regulating Valve Adjustment - Set shut-off

point at least 10 F below condensing temperature

to be maintained at maximum load, but not above

90 F. Select shut-off point high enough to close

valve when unit is not operating.

LUBRICATION

Compressors are charged with oil at the fac

tory. Oil quantities are given in Table 12.

Maintain oil level at center of sight glass.

When adding oil, use only a dehydrated, wax-

free refrigeration grade oil of suitable viscosity.

Compressors

are

charged

with

refrigeration

grade oil (Carrier No. PP36) for evaporator tem

peratures above -45 F. When evaporator tempera

ture is -40 or below, replace oil with Carrier

No. PP33.

WfiMAt. ON COOLiMG TOWSfi;

oas«os4.^as7, iz?

Fig. 18 - Condenser Minimum Pass Connections

1072