Table 11 - crankcase heater relay (60-cycle), Compressor operation, Íttiíítedxateíy aíter ¿starting: cort^eascr – Carrier 5H User Manual

Page 7: Fig, 12 - correct belt alignment, Refrigerant piping

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 10 - 5F,H Compressor Crankcase

Heater Package

COMPRESSOR

5F20,30,40,60

5H40,46,60,66

5H80,86,120,126

ELECTRICAL

CHARACTERISTICS

Volts Watts

115

230

115

230

115

230

100

100

200

200

200

200

PACKAGE NUMBERS

-5-F—20---------381

-5-F—20---------391

-5-H—40-------- 381

-5-H—40-------- 391

-5-J__40-------291

-5-J—40------- 291

Table 11 - Crankcase Heater Relay (60-Cycle)

CONTROL CIRCUIT VOLTAGE

115

208/230

PART NUMBER

HN61AJ-101

HN61AJ-108

COMPRESSOR OPERATION

Motor Rotation - Start motor before connecting to

compressor. Rotation direction must be same as

arrow cast on pump cover or plate attached near

pump end bearing housing. To rotate compressor

in opposite direction the manually reversible oil

pump must be reversed as follows:

5H120 AND 126; ALL 5F COMPRESSORS - Remove

6 capscrews from oil pump cover. Do not damage

gasket. Rotate cover 180° and replace. Arrow will

now be on top and show new direction of rotation,

5H40,46,60,66,80 AND 86 COMPRESSORS - Drain

oil below level of end bell cover. Remove end bell

assembly and pump end cover. Rotate cover 180°

and replace. Reverse direction of external arrow

(shows compressor rotation without removing end

bell). Arrow on pump end cover must match arrow

on main bearing housing. Replace end bell and

refill with specified oil.

CAifTJON* it

b&twsen oli putnp

cowr stsi oil ï«tnî*> IS- àaîîaagôd, relace xt'with

correct gasket onJy. Check oïî ^CÊinp rotor esá

■ cîearaixce í

Checktcéí ■ ísresstfre

íttiíítedxaTeíy aíter ¿starting: cort^eascr.

Oil Safety Switch installation instructions are in

cluded in Oil Safety Switch Packages.

Motor Fastening Set supplied with all compressor

units (except 5F20,30) includes motor blocks and

shims

for

motor

alignment;

capscrews,

plate

washers and lock washers for fastening motor to

base; taper dowel pins for securing motor position

on

base

(after

alignment);

beveled

washers

for

fastening unit base to vibration isolators or floor.

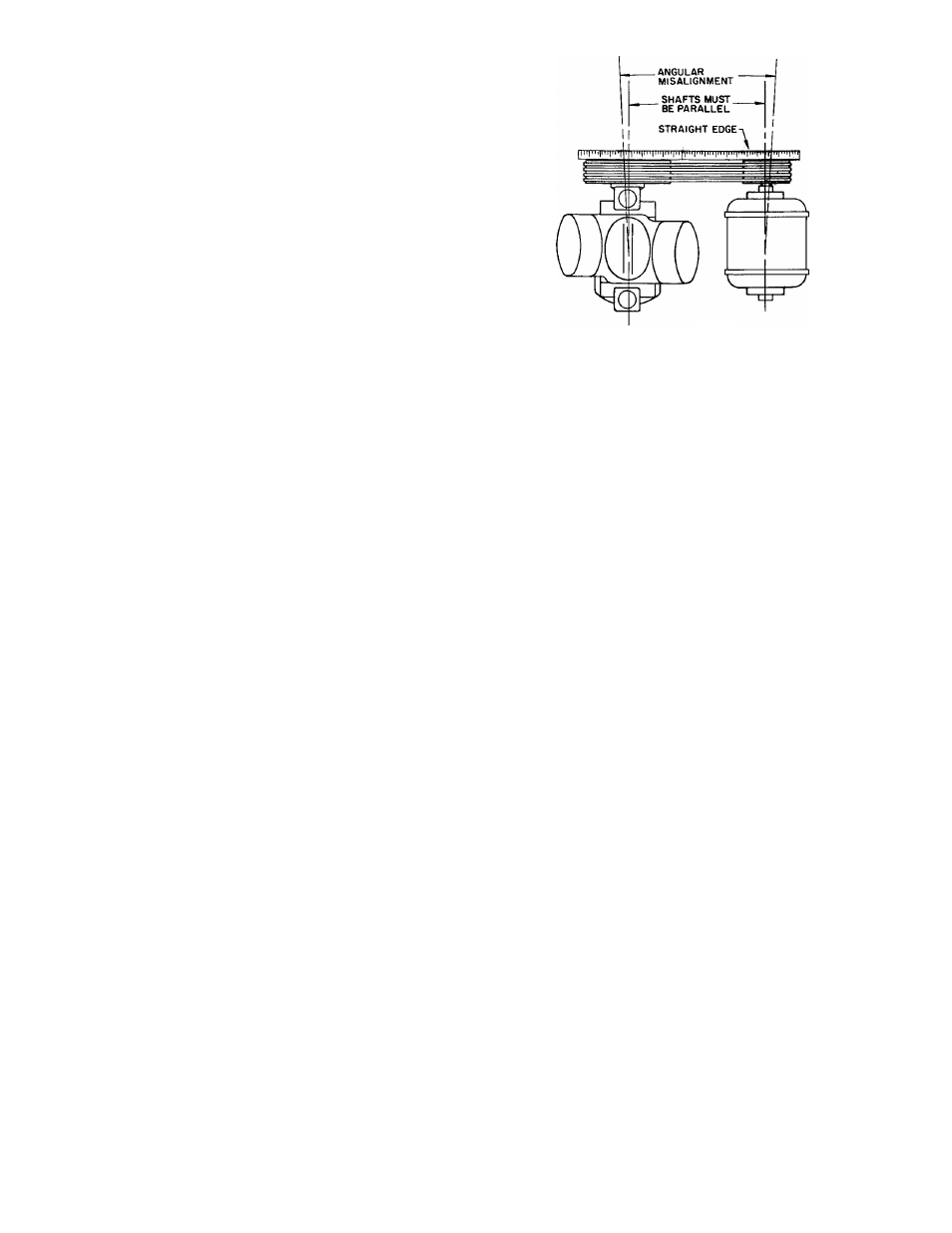

Install and Align Belt Drive — Clean motor and

compressor

shafts,

flywheel

and

motor

pulley

bores with fine emery cloth.

Install motor pulley, flywheel and keys tightly

on shafts.

Slide motor forward on rails to install belt. Line

up flywheel and motor pulley with a straight edge

Fig, 12 - Correct Belt Alignment

or string (Fig. 12) or by placing a round rod in belt

grooves. Slide motor pulley on shaft to correct any

parallel

misalignment.

Loosen

motor

hold-down

bolts and turn motor frame to correct any angular

misalignment.

Move motor backward with adjusting bolts to

tighten belts. Tighten belts just enough to prevent

slippage.

Determine belt tension by (a) loosening belts

until they slip when motor starts (belt squeals),

then

tighten

enough

to

eliminate

slippage,

(b)

amount belt is depressed at center of span (heavier

belts deflect approximately 1 inch for a 24-inch

span; lighter belts or longer span deflect propor

tionately more)

Install Direct Drive — Instructions for installation

are in the coupling package

Securing Motor to Base — Align motor and

compressor. Drill and ream two holes thru motor

feet and base. Secure motor to base with two

#6 X 2-1/2 taper dowel pins provided in motor

fastening

set.

Locate

holes

diagonally

opposite

motor feet. Use 9/32-inch diameter drill and #6

taper reamer.

REFRIGERANT PIPING

Refer to Carrier System Design Manual, Part

3 for proper piping techniques.

Venting - Replace vent plugs (front and rear heads)

and drain plug (front head) with nipples and valves

if frequent draining of condenser (water side) is

desired.

Refrigerant Drier - See System Design Manual,

Part 3, Page No. 3-75.

Felt Filter - Install felt filter (supplied with com

pressor) in suction line screen. Remove after 50

hours of compressor operation. If dirty, clean with

kerosene or neutral spirits and replace for another

50 hours operation. If filter is clean, leave it out.

Indicate on tag that filter has been cleaned and

reinstalled.

569