Compressor bolted to concrete base - see fig. 8, Fig. 11 - wiring schematic single pumpout cycle – Carrier 5H User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 9 - Dimension "C" (ft-in.) (Fig. 10)

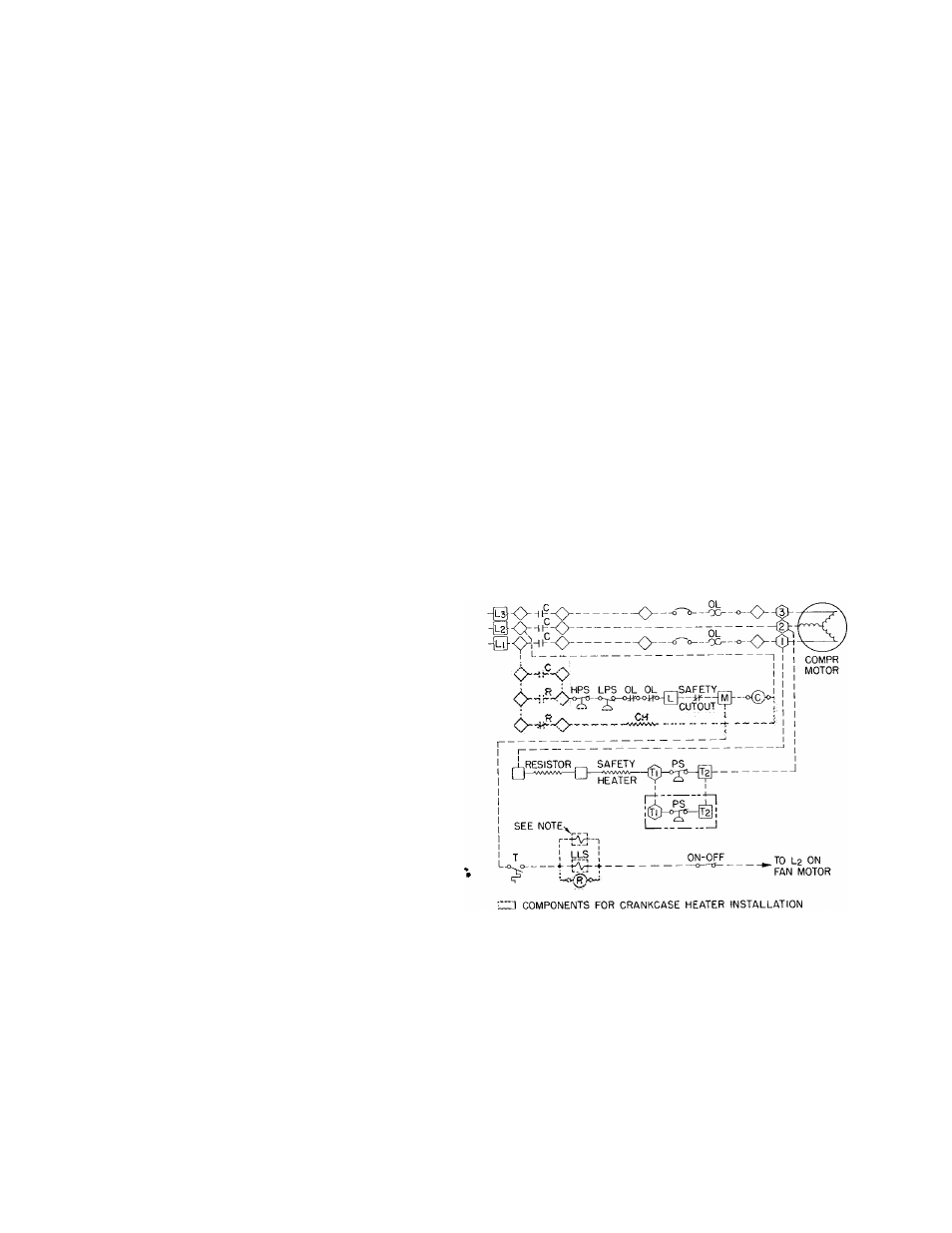

CRANKCASE HEATER

COMPR

5F

5H

20

30

40

60

60*

40

46

60

66

60*

66

*

80

86

120

126

DRIVE

Belt

2-8-3/8

2- 8-3/8

3- 7-7/8

3- 7-7/8

4- 2-3/4

4-2-3/4

4-7-3/4

4-7-3/4

J

Direct

3-7-7/8

3- 7-7/8

4-

2-3/4

4-2-3/4

4-2-3/4

4-2-3/4

4-2-3/4

4-5-1/2

4-

5-1/2

5-

9-3/4

5-9-3/4

5-9-3/4

5-9-3/4

*Overs

bas

Loosely

connect

compressor

discharge

line

and adjust condenser position so discharge line

is in line with condenser inlet. Assemble discharge

lines

for

5H

Series

compressors

as

shown

on

special

diagram

sheet

included

in

5H

condenser

piping packages. Before making joints, try coup

ling or belt guard to ensure piping clearance.

Place strips of Fabrica provided between lower

support straps and condenser. See Fig. 10.

Tighten lower strap enough to lift condenser

off stands.

Sweat discharge line to condenser. Adjust con

denser position as required to prevent distortion

of discharge line. Instructions are included in the

piping assembly package.

Place

Fabrica

strips

(see

Fig.

10),

between

condenser and upper straps. Tighten strap bolts

to secure condenser to stand. NOTE; Use lower

straps only for 5F20 and 30 units. Place the two

extra strips of Fabrica between top of condenser

and base. Assemble discharge line as described

above.

Compressor Bolted to Concrete Base - See Fig. 8.

Set compressor level on foundation bolts. (Level

in two directions.) Removal of discharge shut-off

valve exposes face of mounting flange on com

pressor which can be used as a leveling pad. Lo

cate and level motor slide rails. Provide for 3/8

inch to 1/2 inch grout. Tighten foundation bolts

handtight. Do not use wrench.

Wet top of concrete, pour grout and tamp to

fill all spaces between machinery and concrete.

Allow grout to dry slightly then trowel smooth.

Suggested mixture for grout is one part Port

land cement to two or three parts of sharp sand.

Tighten foundation bolts moderately tight when

grout has hardened for 24 to 36 hours. Overtight

ening bolts may cause compressor misalignment.

Energizing crankcase heater helps prevent oil

and refrigerant from mixing and accumulating in

crankcase when compressor is off.

Wire heater to relay or set of normally closed

contacts in compressor starter so it will be de

energized when compressor is operating.

Installation of Heaters- Remove rubber plug from

crankcase heater casing (see Fig, 1 thru 4).

Insert

heater

element

entirely

into

casing.

Element should fit snugly, not loosely.

Wire in accordance with local codes and dia

gram (Fig. 11).

Relay Coil voltage is determined by control cir

cuit voltage which must be specified when ordering

relays.

Mount relays vertically.

When crankcase heater is installed, system can

operate on a single pumpout cycle as shown in

schematic. Fig. 11.

Crankcase heater packages are given in Table

10 and corresponding relay is in Table 11. When

two heaters are usedona 5H80or 120 compressor

only one relay is required.

NOTE; Auto-suction stop valve (flooded systems only)

c

— Compressor

□

CH

— Crankcase Heater

HPS — High Pressure Switch

o

LLS

— Liquid Line Solenoid

EPS — Low Pressure Switch

OL

- Overload

0

PS

— Pressure Switch

R

- Relay

T

— Thermostat

—

Terminal Connections,

Marked

Component Connection,

Unmarked

Component Connection,

Marked

dd W iring

Fig. 11 - Wiring Schematic Single Pumpout Cycle