Typical wiring connections, Gl0ï – Carrier 48GH User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

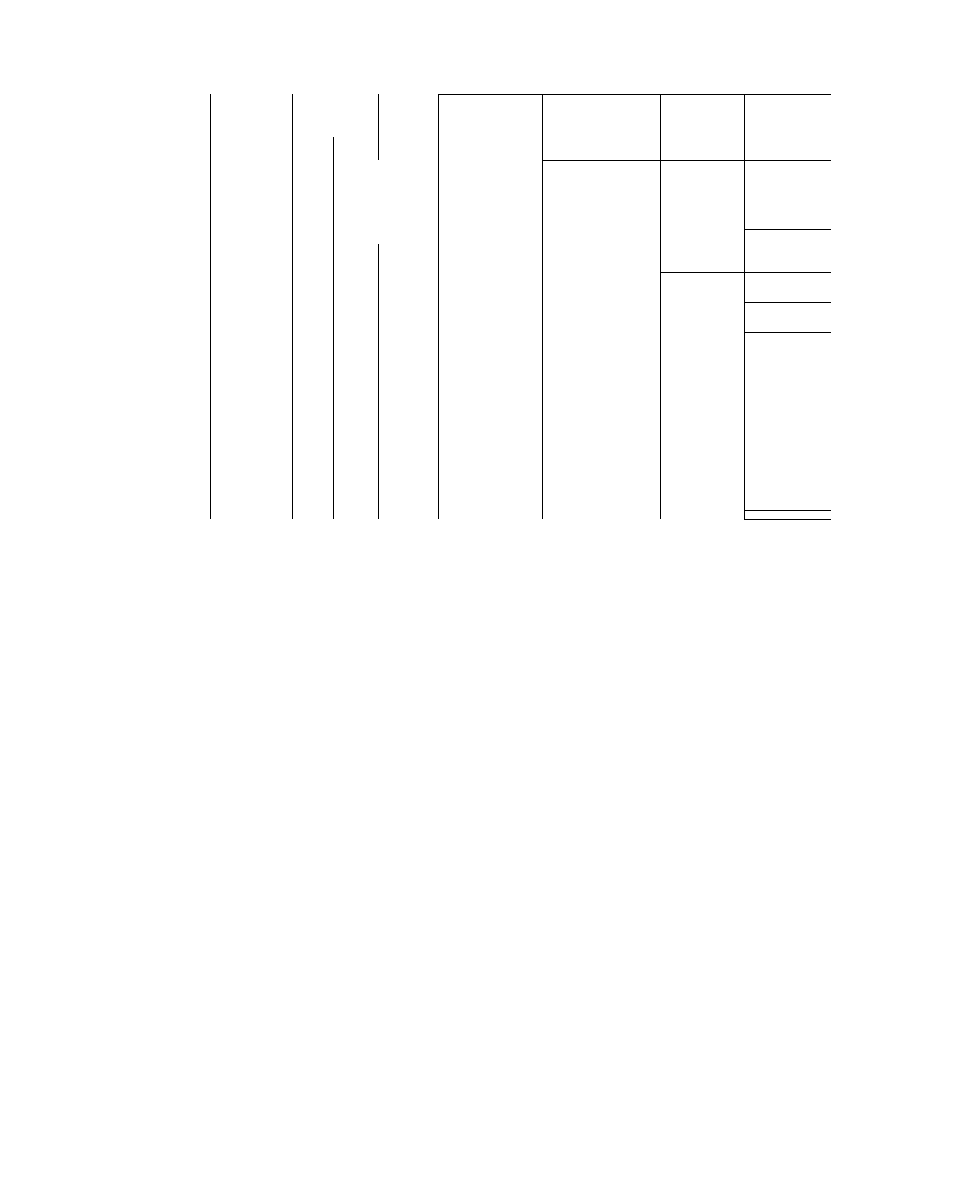

Table 2 — Electrical Data

MODEL

48

GL0Ï¥

GL024

GH024

GL030

GH030

GL036

GH036

GL042

GH042

GL048

GH048

GL060

GH060

*Use only copper wire for field connections to unit Wire size is

based on 60 C or 75 C copper conductor at 86 F (30 C) ambient

temperature and ampacity shown in table If other than 60 C or

75 C copper conductor is used, if ambient temperature is above

86 F, or if voltage drop of the wire exceeds 2% of total rated

Adhere to the following criteria when selecting,

sizing, and installing duct system:

1. Select and size ductwork, supply-air registers

and return-air grilles according to Carrier Sys

tem Design Manual, Part 2. System airflow must

be within range of temperature rise and external

static pressure shown on unit A.G. A. rating plate.

CAUTION: When dtict-sysiem fastening holes

are being drilled into side of Model 4SGH/GL

instead of the unit duct flanges, use extreme care

to avoid puncturing coil or coil tubes,

2. Use a flexible transition between rigid ductwork

and unit to prevent transmission of vibration.

The transition may be screwed or bolted to duct

flanges. Use suitable gaskets to ensure a weather

and airtight seal.

3. Install an external, field-supplied air filter(s)

in return-air ductwork where it is easily accessible

for service. Recommended filter sizes are shown

in Table 1.

4. Size all ductwork for maximum required airflow

(either heating or cooling) for unit being in

stalled. Avoid abrupt duct size increases or

decreases.

5. Adequately insulate and weatherproof all duct

work located outdoors. Insulate ducts passing

OPER

VOLTAGE

TOTAL

AMPS

MAX BRANCH

UNIT AMPACITY

MIN

MAX WIRE

SERIES

V/PH

RANGE

CIRCUIT FUSE

FOR

WIRE SIZE

LENGTH

Min

Max

SIZE (Amps)

WIRE SIZING

(AWG)»

(ft)*

300

208-230/1

197

253

11 4

20

13 8

14

67

300

208-230/1

197

253

160

30

19 4

12

76

300

208-230/1

197

253

17 3

30

20 7

10

112

300/310

208-230/1

197

253

19 3

35

23 4

10

100

300/310

208-230/1

197

253

19 1

35

23 2

10

101

300/310

208-230/1

197

253

25 0

45

30 0

10

77

500/510

208-230/3

187

253

18 6

35

21 9

10

121

600/610

460/3

414

506

9 1

15

10 8

14

218

300/310

208-230/1

197

253

24 8

45

29 8

10

78

500/510

208-230/3

187

253

19 5

35

22 8

10

116

300

208-230/1

197

253

26 4

50

31 8

8

117

500

208-230/3

187

253

21 9

40

25 8

10

103

300

208-230/1

197

253

26 2

50

31 6

8

117

500

208-230/3

187

253

21.3

40

25.2

10

106

300/310

230/1

207

253

30 3

60

36 3

8

107

500/510

208-230/3

187

253

26 6

45

30 8

8

135

600/610

460/3

414

506

11 7

20

13 5

14

169

300/310

230/1

207

253

29 5

60

35 5

8

110

500/510

208-230/3

187

253

24 6

45

28 8

10

92

300/310

230/j

207

253

43 4

60

52 3

6

116

500/510

208-230/3

187

253

30 4

50

35 6

8

118

600/610

460/3

414

506

15 3

25

17 9

12

205

300/310

230/1

207

253

43 7

60

52 6

6

116

500/510

208-230/3

187

253

29 4

50

34 6

8

122

--- -

voltage of the unit, determine wire size from ampacity shown

and National Electrical Code (NEC) Wire lengths shown are

measured one way along wire path between unit and service

panel for minimum voltage drop

thru an unconditioned space, and use a vapor

barrier in accordance with latest issue of

SMACNA and NESCA minimum installation

standards for heating and air conditioning

systems. Secure all ducts to building structure.

6. Flash, weatherproof and vibration-isolate all

openings in building structure in accordance

with local codes and good building practices.

Typical Wiring Connections

WARNING: Iftiii cabinet amst have an

interrupted,

nnbroten

electrical

gronud

to

minimize the possibiSty of personaf injury

if zxi eiectEical fault should occur. His ground

may consist of electrkai wire connected to unit

ground lag in control cotnpartnrent, or conduit

approved for electrical ground when installedin

accordance with National Electric^ Code and

local electrical codes. Do not use gas piping;

as an electrical ground. A failure to follow this

warning could result in the installer being liable

for the personal injury of others.

CAUTION: A failure to follow these precau

tions could result in damage to unit being

installed:

(%