Fig. 8 — burner flames – Carrier 48GH User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Proceed as follows to measure and change

manifold pressure:

a. Turn off gas to unit.

b. Remove pipe plug on gas valve outlet identified

as PRESS TAP, then connect manometer at

this point.

c. Turn on gas to unit and start heating section.

d. Measure and change manifold pressure with all

burners fired to obtain desired gas input.

e. Turn off gas to unit, remove manometer from

gas valve, and replace pipe plug.

ADJUSTING

BURNER

AIR

SHUTTERS

After burners have operated at full input for at least

10 minutes, adjust primary air to each burner to

ensure optimum heating performance. Make these

adjustments when unit is being installed and during

routine maintenance inspections at beginning of

each heating season. Be sure that each burner is

clean and free of deposits before adjusting primary

air.

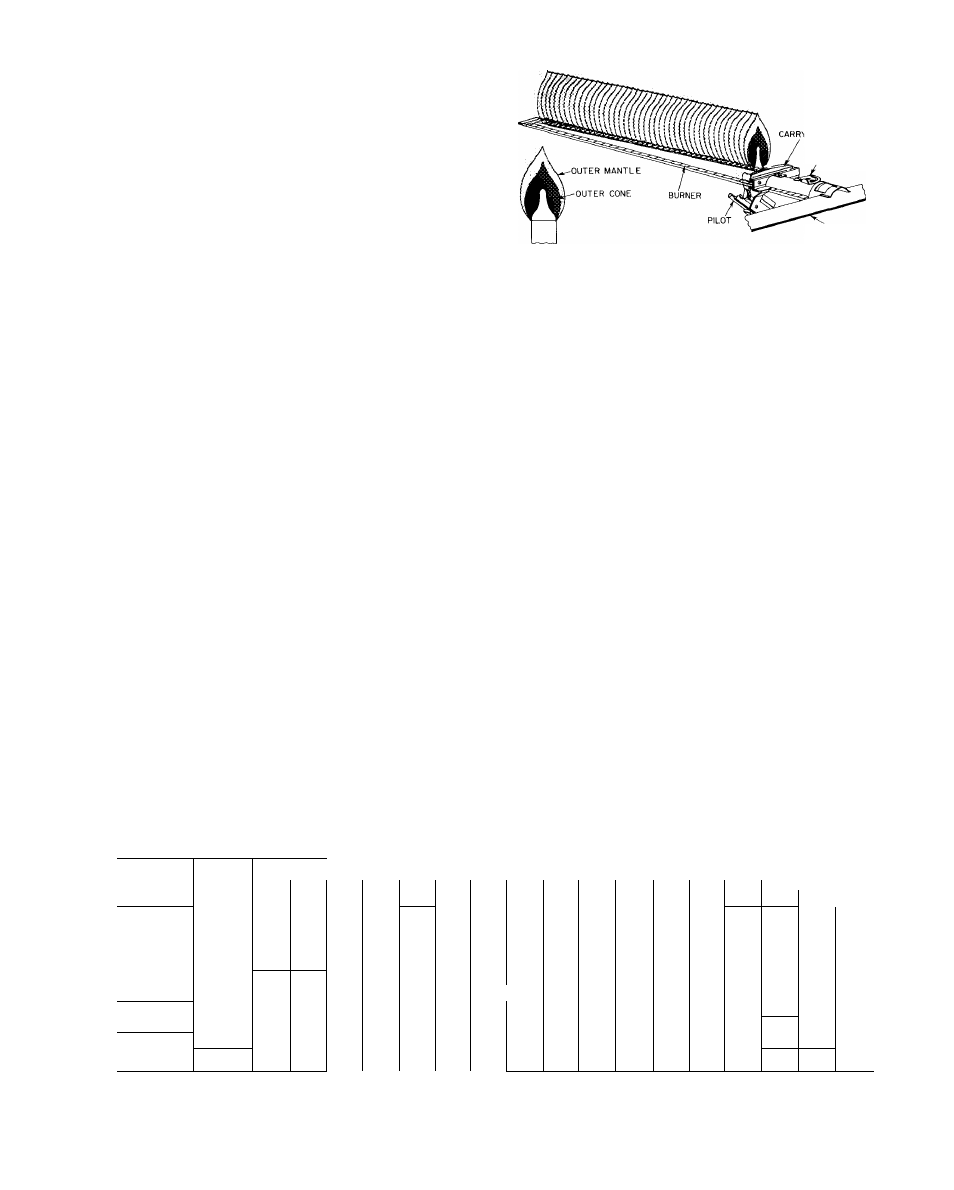

The primary air to each burner is regulated by

burner air shutter on each burner. See Eig. 8 for

location of burner air shutter. With all burners

operating, adjust primary air to each burner as

follows:

1. Loosen locking screw that secures air shutter

in place on burner, then partially close air shutter

until a slight yellow tip appears on top of burner

flames.

2. Open air shutter very slowly until yellow tip just

disappears, then secure air shutter in place with

locking screw.

3. Repeat steps 1 and 2 for each burner.

After air shutter adjustments have been com

pleted, observe that flames on each burner are light

blue and “soft” in appearance, and that flames are

same height along the entire length of each burner.

See Fig. 8.

AIR

SHUTTER

MANIFOLD

Fig. 8 — Burner Flames

BLOWER HEAT-RELAY OPERATION — Heat

relay (see Fig. 6 and unit wiring diagram) is located

in control box and adjusts to permit either longer or

shorter OFF cycles. The ON cycle automatically

adjusts as OFF cycle changes. Adjusting lever on

relay is factory-set at center position to provide

optimum performance for most installations. On

unusual installations, or where line voltage is

considerably above or below rated voltage, length

of time blower remains on may require increasing or

decreasing. To increase blower operation time,

move adjusting lever toward right-hand position.

In this position, control makes contact sooner and

"takes maximum time to break contact. To decrease

blower operation time, move lever toward left-

hand position.

AIRFLOW AND TEMPERATURE RISE —^

Temperature rise is temperature difference between

air in return duct and air in discharge duct at unit.

Heating section of each size of unit is designed and

approved for heating operation within temperature

rise range stamped on unit rating plate.

Table 4 shows the approved temperature rise

range for each unit, and air delivery (cfm) at various

temperature rises for both A.G.A.-certified gas

input ratings. Heating operation airflow must

produce a temperature rise that falls within

approved range.

Table 4 — Air Delivery (Cfm) at Indicated Temperature

Rise and Rated Heating Input

MODEL NO

HEATING

TEMPERATURE RISE (F)

48

INPUT

.

-

------

--

- ___

-

- “ " —

(Btuh)

35

37 5

40

42 5

45

47 5

50

52 5

55

57 5

60

62.5

65

67 5

70

75

GL018,024,

40,000*

794

741

694

654

617

585

556

529

505

483

463

444

427

397

383

370

030

50,000

1032

963

903

850

802

760

722

68"8^

657

628

602

578

556

535

516

498

481

GH024,030

60,000'

1190

1111

1042

980

926

877

833

794

758

725

694

667

641

617

595

575

556

GL036,042

75,000

1548

1444

1354

1275

1204

1140

1083

1032

985

942

903

867

833

802

774

747

722

GH042

80,000*

1587

1481

1389

1307

1235

1170

1111

1058

1ÒÌÒ

966

926

889

855

823

794

766

741

GL048

100,000

2063

1926

1806

1699

1605

1520

1444

1376

1313

1256

1204

1156

1111

1070

1032

996

963

GH036,048

100,000*

1984

1852

1736

163£^

1543

1462

1389

1323

1263

1208

1157

1111

1068

1029

992

958

926

GL060

125,000

2579

2407

2257

2124

2006

1901

1806

1720

1641

1570

1505

1444

1389

1337

1290

1245

1204

GH060

1 20,000*

2381

2222

2083

1961

1852

1754

1667

1587

1515

1449

1389

1333

1282

1235

1190

1149

nil

150,000

3095

2889

2708

2549

2407

2281

2167

2063

1970

1884

1806

1733

1667

1605

1548

1494

1444

‘These inputs are the minimum rated inputs using factory-installed burner

orifices Higher inputs shown for each size are the maximum rated inputs

using field-installed, optional burner orifices that are indicated on unit

rating plate

NOTE:

Models

48GL018,024,036;

48GH024,030

have

an

approved

tem

perature rise range of 35 to 75 F All other units have an approved tempera

ture rise range of 45 to 75 F

11