Carrier 48GH User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

€

NOTE: Screw holes in vent stack extension and

unit top are not symmetrically located; thereby

ensuring proper orientation when installing these

components.

Refer to Fig. 4 and install vent cap as follows:

1. Place combustion-air duct over combustion-air

opening in unit top, and line up screw holes in

duct with holes in top. Secure duct to top using

screws with rubber washers (provided).

2. Place gasket and vent stack extension thru hole

in combustion-air duct, orient screw holes in

base of vent stack extension with holes in unit

top, and secure gasket and vent stack extension

to unit top using screws provided.

3. Form flat wire screen (provided) into circular

shape around protruding lip of combustion-air

duct, and bend wire ends thru holes of screen

mesh to secure screen in place. Make sure that

no sharp edges are left exposed.

4. Place vent cap sleeve inside vent stack extension.

Orient spring clip of vent cap with slot in

extension. Be sure that clip snaps into slot to

secure clip onto extension.

Typical Piping

— The gas supply pipe enters unit

thru access hole provided. See Fig. 1 for location.

The gas connection to unit is made to the 1/2-in.

FPT gas inlet on gas valve. See Fig. 6.

Install a separate gas supply line that runs

directly from meter to heating section. Do not use

cast-iron or galvanized pipe. Check local utility for

recommendations concerning existing lines. Choose

a supply pipe that is large enough to keep pressure

loss as low as practical. Never use pipe smaller than

the 112-in. FPT gas inlet on gas valve.

When installing gas supply line, observe local

codes pertaining to gas pipe installations. Refer to

National Fuel Gas Code ANSI Z223.1-1974 in

absence of local building codes. Adhere to pertinent

recommendations.

1. Avoid low spots in long runs of pipe. Grade all

pipe 1 /4-in. in every 15 ft to prevent traps. Grade

all horizontal runs downward to risers. Use risers*,

to connect to heating section and to meter.

2. Support all piping with appropriate hangers, etc.

Use a minimum of one hanger in every 6 feet. For

pipe sizes larger than 1/2 in., follow recom

mendations of national codes.

3. Apply joint compounds (pipe dope) sparingly

and only to male threads of joint when making

pipe connections. Use only pipe dope that is

resistant to action of liquefied petroleum gases

as specified by local and/or national codes.

Never use teflon tape.

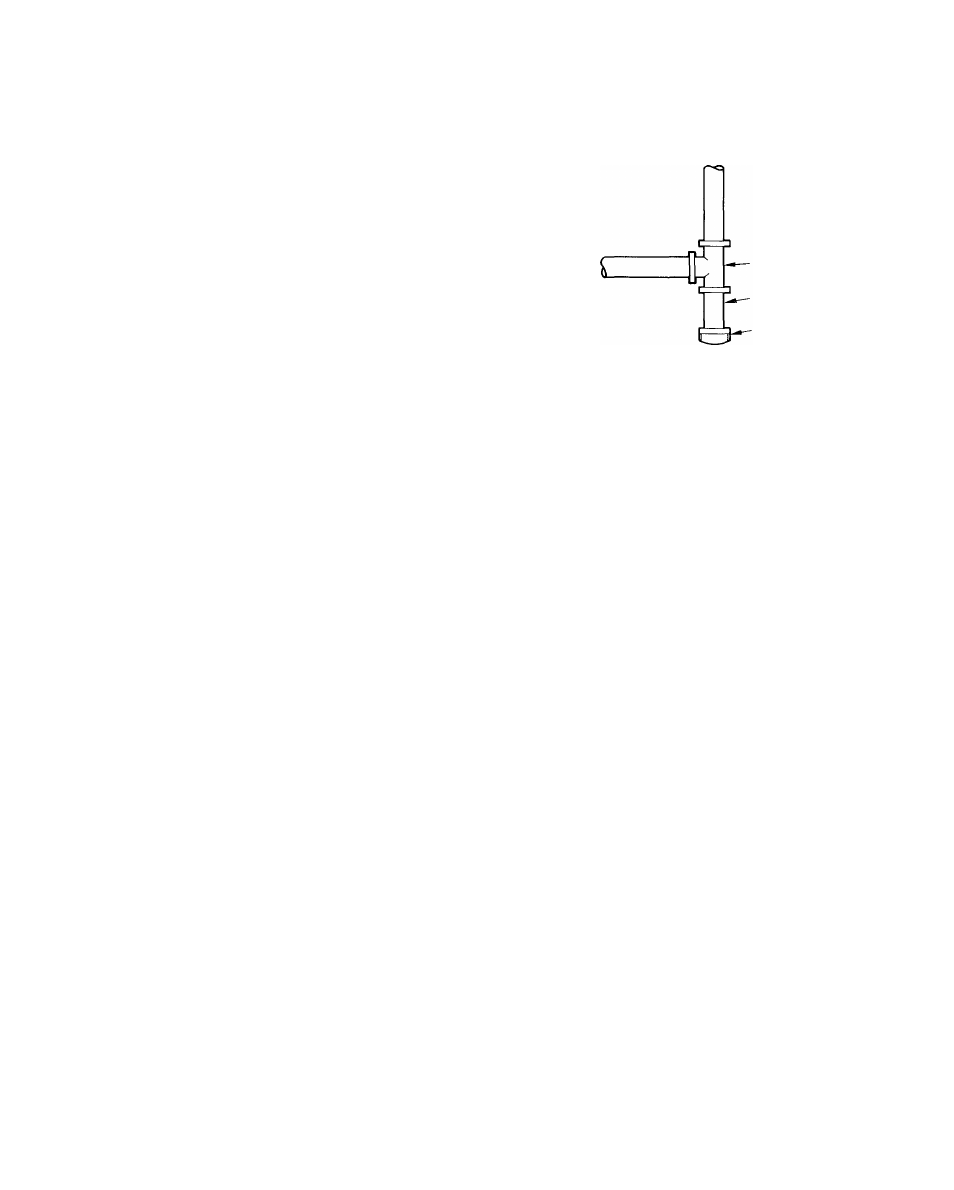

4. Install a sediment trap in riser leading to the

heating section. This drip leg functions as a trap

for dirt and condensate. Install trap where con

densate cannot freeze. Install this sediment trap

by connecting a piping tee to riser leading to

heating section so that straight-thru section of

tee is vertical. See Fig. 5. Then, connect capped

nipple into lower end of tee. Extend capped

nipple below level of gas controls.

-TEE

-NIPPLE

CAP

Fig. 5 — Sediment Trap

5. Install an accessible, external, manual shutoff

valve in gas supply pipe within 6 ft of heating

section. Install a 1/8-in. NPT plugged tapping

that is accessible for test-gage connection

immediately upstream of gas supply connection

to heating section.

6.

Install ground-joint union close to heating

section between gas valve and external manual

shutoff valve.

CAUTION: Unstable operaiton may occur,

parttcüïariy -ander Mgh-wiiKi coiiditions, wh.cn

gas valve and mardfold assembly are forced out

of poskîoo while connecting improperly routed

rigid gas piping to gas valve. Use a backup

wrench when making connection to avoid strain

on, or distortion of, gas control piping.

7. Use flexible gas pipe to make connection between

rigid gas piping and gas valve where permitted

by local codes. Flexible pipe ensures proper

alignment between manifold orifices and burner.

WARNING: Never use a match or other open

Same when, checking for gas leaks.

8. Check for gas leaks at all field-installed and

factory-installed gas lines after all piping connec

tions have been completed. Use soap-and-water

solution (or method specified by local codes

and/or regulations).

Duct Connections

— Model 48GH/GL has duct

flanges on the supply- and return-air openings on

side of unit. See Fig. 1 for connection sizes and

locations.

W'AR-NiNG; The desigaand to.stahatioa.ofduct

system must be in acoordarice with standard&of

National Fire ProtectÎoa Association for

m&tahattou of nopresideace-type air condi-

tiimiag and veutiiatmg systems, NFPA No,

codes atïd ordinances-