Stallation data, Venting – Carrier 48GH User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

3/4-in. galvanized pipe, or

plastie pipe. Do

not undersize the tube. Pitcfi drain tube downward

at a slope of at least 1 in. in every 10 ft of horizontal

run. Be sure to check drain tube for leaks.

Condensate water can be drained directly onto

roof in rooftop installations (where permitted) or

onto a gravel apron in ground-level installations.

When using a gravel apron, make sure it slopes

away from unit.

TO DRAIN

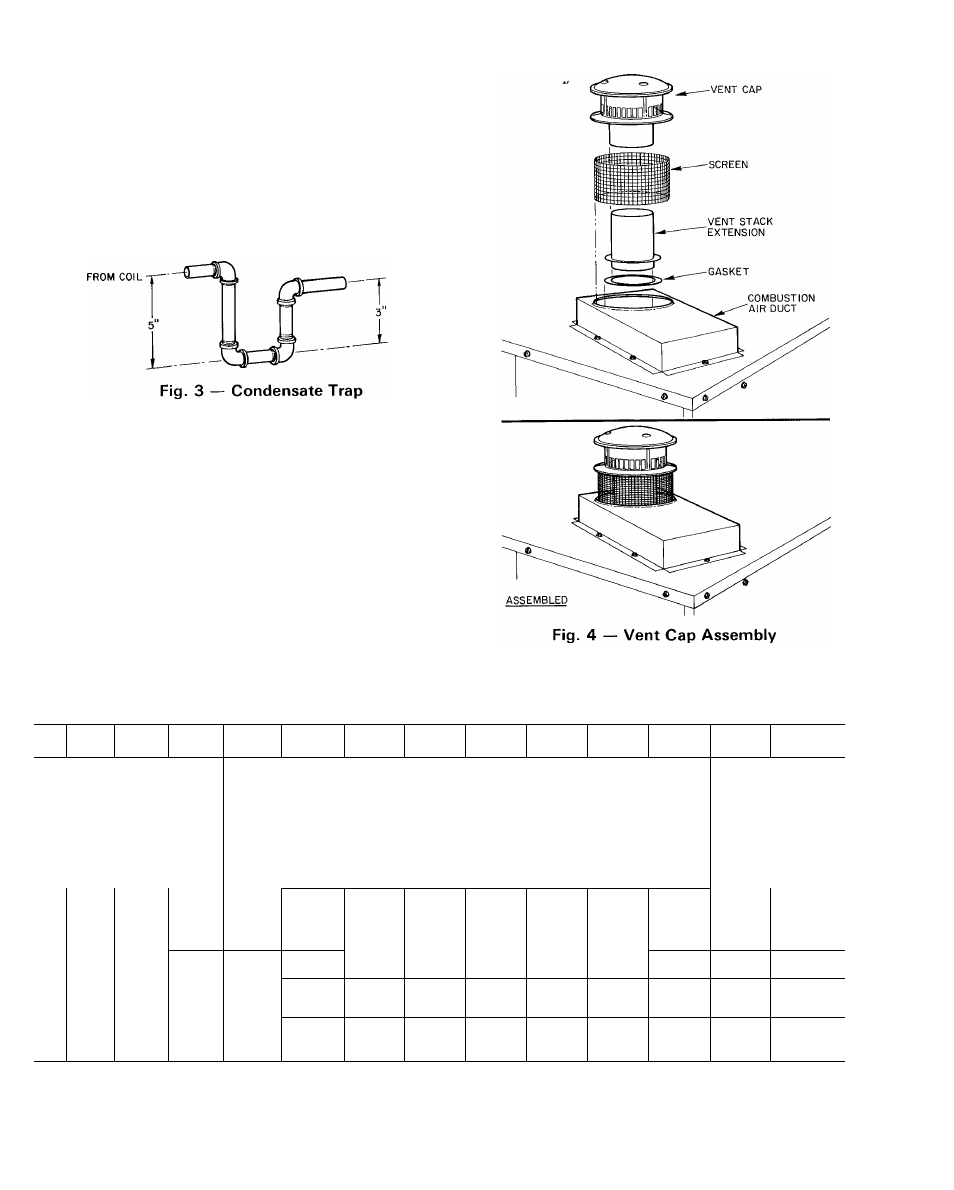

Venting

— The vent-cap and combustion-air duct

assemblies are shipped in either the blower or

control compartment. Remove access doors to

locate assemblies. See Fig. 1 for door locations. Vent

stack extension is shipped either in air hole in unit

top or fastened to back of the control box or in

blower compartment.

CAUTION: Vestiug systetu ss

ea-

s»£« proper ventiijg. Vejit-ci^ assembly tnaslbe

ins.taSed as indicated in this setikm, of Instalia-

tioo liistructtosis.

stallation Data

042

00

GL042

500

GH042

300

GH042

500

GL048

300/310

GL048

500/510

GL048

600/610

GH048

300/310

GH048

500/510

GL060

300/310

GL060

500/510

GL060

600/610

GH060

300/310

GH060

500/510

i- 5-5/8

6- 0-3/8

6- 0-3/8

i-

8-5/8

3- 8-5/8

3- 8-5/8

MO-1/8

4- 6- 1/8

4- 6- 1/8

2- 0

2- 8

2-8

1- 1-1/4

1- 1-1/4

1- 1- 1/4

3- 8-7/8

0- 8-7/8

0- 8-7/8

3- 1-3/8

0- 1- 3/8

0- 1- 3/8

0-10

0-10- 1/2

0-10-1/2

1-10-5/8

2- 0- 11/16

2- 0- 11/16

4- 1

3- 10

4 -1

>72

672

672

672

768

768

768

768

768

951

951

951

951

951

137

437

437

437

499

499

499

499

499

618

618

618

618

618

120

420

440

440

535

535

535

555

555

575

575

605

605

605

130

430

450

450

545

545

545

565

565

585

585

615

615

615

1,000

60,000

80,000

80,000

80,000

80,000

80,000

100,000

100,000

100,000

100,000

100,000

1 20,000

1 20,000

>,000

75,000

100,000

100,000

100,000

100,000

100,000

125,000

1 25,000

1 25,000

1 25,000

1 25,000

150,000

1 50,000

400

1400

1400

1400

1600

1600

1600

1600

1600

1981

1981

1981

1981

1981

) 15

0 15

0 15

0 15

0 20

0 20

0 20

0 20

0 20

0 20

0 20

0 20

0 20

0 20

mum recommended filter areas when these units have been field converted for operation at maximum rated

heating input

.fAll units have a minimum and maximum A G A -certified rated heating input and are manufactured with burner

orifices for heating operation at minimum rating

Units may not be derated below this minim um rating