A caution, 5^yel - -s, Table 4—air delivery (cfm) performance – Carrier 50QQ User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

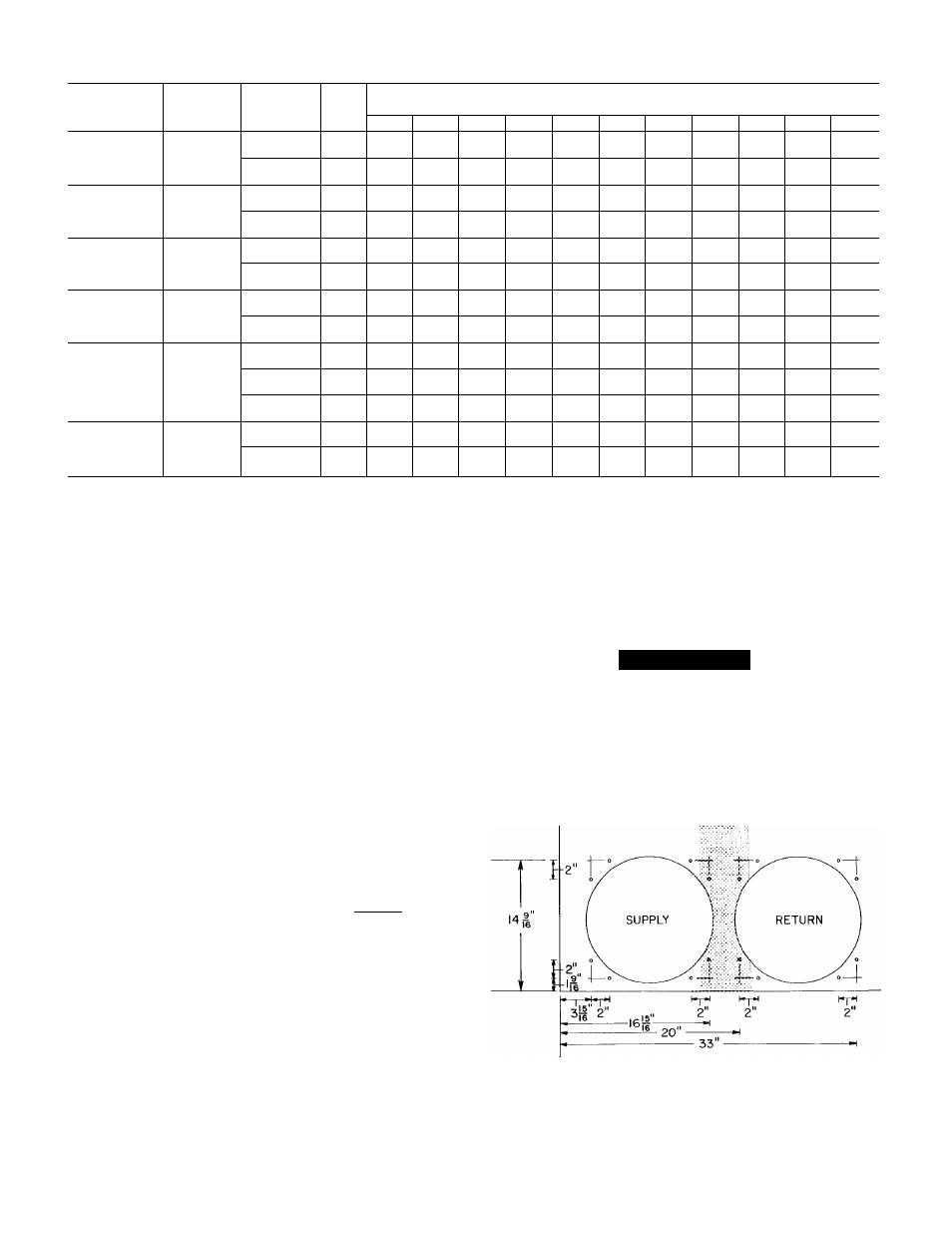

Table 4—Air Delivery (Cfm) Performance

MODEL

50QQ

UNIT

VOLTAGE

BLOWER

MOTOR

SPEED

COIL

EXTERNAL STATIC PRESSURE (in. wc)

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Low

Dry

___

—

___

___

—

800

730

640

_

—

018-10

230

Wet

—

_

—

—

—

750

680

550

—

—

—

High

Dry

_

—

—

—

—

820

680

550

—

—

Wet

—

—

—

—

785

685

575

—

—

—

Low

Dry

1450

1410

1375

1320

1345

1175

1090

985

850

760

024-10

230

Wet

1390

1340

1290

1225

1165

1105

1020

915

740

_

_

High

Dry

1500

1475

1435

1390

1335

1260

1180

1090

980

840

—

Wet

1460

1405

1350

1295

1255

1190

1110

1020

870

—

—

Low

Dry

___

___

1425

1360

1295

1235

1160

1080

995

925

815

030-

230

Wet

—

—

1380

1315

1250

1190

1125

1045

960

895

790

10&30

High

Dry

___

___

1500

1425

1245

1275

1190

1120

1020

935

830

Wet

—

_

1450

1375

1295

1230

1145

1080

985

905

805

Low

Dry

__

___

1440

1400

1345

1290

1225

1140

1040

930

—

036-

230,

Wet

—

1400

1365

1290

1240

1185

1090

990

890

—

10&30

460

High

Dry

___

___

1500

1460

1410

1345

1270

1195

1075

930

—

042-10

Wet

—

_

1465

1430

1365

1300

1230

1145

1020

890

—

Low

Dry

1850

1810

1770

1725

1685

1640

1600

1535

1480

1410

1345

Wet

1820

1775

1730

1695

1650

1610

1555

1500

1440

1385

1320

042-30

230,

Med

Dry

1960

1915

1885

1830

1780

1725

1655

1600

1540

1470

1400

048-

460

Wet

1895

1880

1850

1795

1745

1690

1620

1565

1510

1445

1375

10&30

High

Dry

2230

2160

2120

2070

2010

1950

1890

1820

1750

1675

1590

Wet

2145

2105

2060

2000

1940

1880

1820

1750

1690

1615

1540

Low

Dry

2395

2365

2335

2290

2245

2205

2150

2100

2050

2000

1915

060-

230,

Wet

2375

2325

2295

2250

2225

2180

2135

2070

2020

1960

1875

10&30

460

High

Dry

2570

2525

2470

2425

2370

2335

2265

2220

2160

2100

2030

Wet

2550

2485

2435

2385

2345

2310

2235

2190

2130

2075

2000

NOTES:

1. Air delivery values are based on 230- or 460-volt unit operating voltage without air filter or optional electric heaters Deduct field-supplied air filter and

electric heater pressure drop to obtain external static pressure available for ducting

2 Dashes indicate portions of table that are beyond blower motor capability,

3 Do not operate unit at a cooling airflow less than 350 cfm for each 12,000 Btuh of rated cooling capacity. Indoor coil icing may occur at airflows below

this point

3. Using duct flange as a template, make sure marked

locations line up with clearance holes on flanges.

4. At marked locations, drill screw engagement holes

using a #26 (.147-in.) twist drill.

GROUND LUG

(IN SPLICE BOX)

I - PHASE

CONN.

TO

DISCONNECT

PER NEC

--GROUND LEAD

L2

__________

__________ ^

BLK

YEL--------1

HEAT PUMP

GROUND LUG

(IN SPLICE BOX)

3-PHASE

CONN.

TO

DISCONNECT

PER NEC

- - GROUND LEAD -

L2----------------------

BLK-------- S

L3

■BLU--------5

-5^YEL - -s

HEAT PUMP

A CAUTION

On 042, 048, do not drill deeper than one inch in shaded

area. Damage to refrigerant coil could result.

5. Attach duct adapters using #10B, V

2

-in. long screws

supplied in accessory kit.

6. Finished kit installation accommodates a 14-in. x 14-in

duct.

A88059

Fig. 7—Line Power Connections

Fig. 8—Duct Fiange Kit Dimensions and Hoie Locations

A88058

ELECTRIC HEATER INSTALLATION-For complete

heater installation data, refer to separate accessory electric

heater Installation, Start-Up and Service Instructions.

#