A caution – Carrier 50QQ User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

2. Start unit and allow to operate until operating condi

tions stabilize and pressures level out.

3. Evaluate system performance and refrigerant charge

level by determining following conditions:

a. High- and low-side pressure gage reading.

b. Dry-bulb temperature of inlet air at outdoor coil.

c. Dry-bulb temperature of inlet air at indoor coil. This

may be read at central return-eiir grille.

d. Compare readings to those listed in Heating Operat

ing Pressures section of charging chart inside unit

(refer to Table 6, part A). The Heating Operating

Pressures portion of the chart is for checking charge

only when unit is in heating mode and outside tem

peratures are below 60 F.

If charge adjustment is necessary, charge can be adjusted

accurately only by blowing the charge, evacuating system,

and recharging unit with correct charge as listed on unit rat

ing plate. A volumetric charging device such as Dial-a-

charge is recommended for use when recharging.

Cooling Mode—A superheat charging label is affixed to elec

trical access door. The label includes a Field Superheat

Charging table (see Table 6, peirt B) and a Required Suction

Tube Temperature (F) chart (see Table 6, part C).

An accurate superheat-, thermocouple-, or thermistor-type

thermometer, a sling psychrometer, and a gage manifold are

required when using superheat charging method for evalu

ating unit charge. Do not use mercury or small dial-type

thermometers. They are not adequate for this type of

measurement.

Proceed as follows:

1. Remove caps from low- and high-pressure service

fittings.

Using hoses with valve core depressors, attach low-and

high-pressure gage hoses to low- and high-pressure

service fittings, respectively.

Start unit in cooling mode. Let unit run until system

pressures stabilize.

Measure and record following;

Outdoor ambient air dry-bulb temperature (F).

Evaporator inlet air wet-bulb temperature (F).

Suction tube temperature (F) at low side service

fitting.

Suction (low side) pressure (psig).

Using Field Superheat Charging table, compare out

door air dry-bulb temperature (F) with evaporator inlet

air wet-bulb temperature (F) to determine desired sys

tem operating superheat temperature.

Using Required Suction Tube table, compare desired

superheat temperature (F) with suction (low side) oper

ating pressure (psig) to determine proper suction tube

temperature.

Compare actueil suction tube temperature with proper

suction tube temperature. Using a tolerance of ± 3 F,

add refrigerant if actual temperature is more than 3 F

higher than proper suction tube temperature, or

remove refrigerant if actueJ temperature is more than 3

F lower than required suction tube temperature.

Metering Device (Dual-Piston Type) Servicing—

See Fig. 11

for dual-piston components. The pistons have a refrigerant

metering orifice through them. The retainers form a stop for

the pistons in the refrigerant bypass mode, and a sealing

surface for liquid line flare connection. To check, clean or

replace piston:

1. Shut off power to unit.

2.

3.

4.

a.

b.

d.

5.

6

.

7.

2. Remove refrigerant from unit using approved refriger

ant removal methods.

3. Remove liquid line flare connections from metering

device.

4. Note position of arrow on metering device body with

respect to unit.

5. Pull retainer out of body. Be careful not to scratch flare

sealing surface. If retainer does not pull out easily,

carefully use locking pliers to remove retainer. Replace

scratched or deimaged retainer.

6. Slide piston out by inserting a small soft wire through

metering hole (18-gage thermostat wire). See that

metering hole, sealing surface around piston cones and

fluted portion of piston are not damaged.

7. Chart on unit access panel illustrates proper arrange

ment and sizes of piston.

8. Clean piston refrigerant metering orifice.

9. Replace retainer 0-ring before reassembling metering

device. 0-ring Part No. is 99CC501052.

LIQUID LINE STRAINERS (to protect metering device),

are made of wire mesh and located in the liquid line on each

side of the metering device. The strainers are pressed into

the line. Remove strainer by threading a #10 sheet metal

screw into strainer and pulling the screw with pliers.

Compressor Removal—

See Table 7 for compressor informa

tion and Fig. 12 for component location. Follow safety

codes, and wear safety glasses and work gloves. Have

quenching cloth available (step 8).

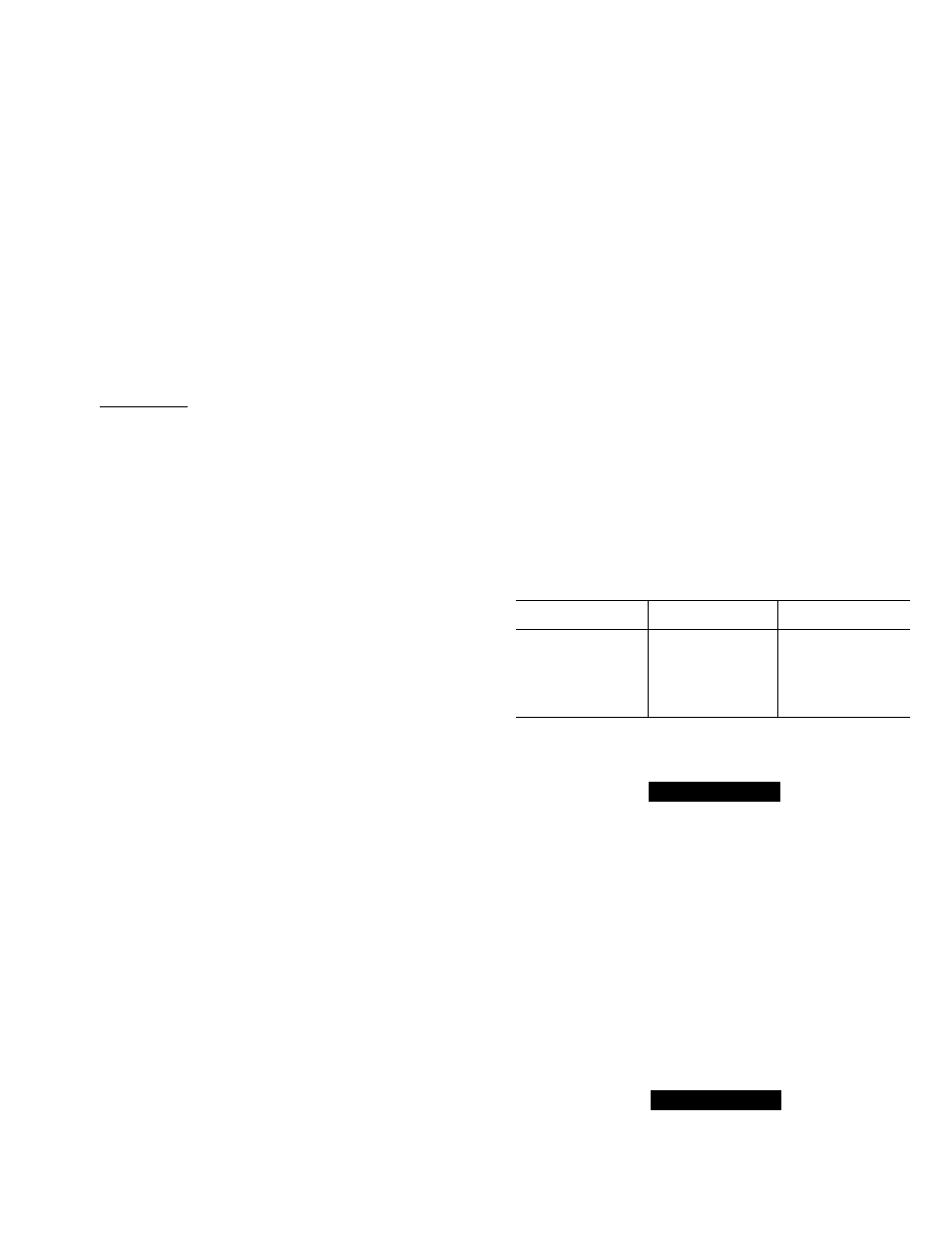

Table 7—Compressor Data

MODEL

SOQQ

PRODUCTION

COMPRESSOR*

OIL

RECHARGE (oz)

018

H22B173

37

024

JD25

44

030

JD30

44

036

JD37

44

042

JD42

44

048

JD45

44

060

H23A623

47

*Refer to compressor nameplate for complete model number.

A CAUTION

Copper tubing is used in unit coils. Do not overheat or

place excessive strain on tubing or damage may result.

1. Shut off power to unit. Remove compressor access

panel to expose compressor. See Fig. 12.

2. Remove refrigerant from unit using approved refriger

ant removal methods.

3. Remove core from suction and discharge line Schrader

fittings.

4. Disconnect compressor wiring at compressor terminal

box.

5. Using a tubing cutter, cut suction and discharge lines

at convenient place near compressor for easy reassem

bly to new compressor with copper slip couplings.

A CAUTION

Excessive movement of copper lines at compressor may

cause a break where lines connect to other system

components.

11