A warning – Carrier 50QQ User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Return Air Filter (Field Supplied)—

Replace disposable filter

4 times a year, clean permanent filter a minimum of 4 times

yearly or as required. Flush permanent filter with hot water,

steam or soak in mild solution of soap or detergent and

water. Allow filters to dry and replace. Refer to filter manu

facturer’s instructions, as required, for other types of

filters.

Outdoor Coil—

Inspect outdoor coil regularly. A dirty coil

can lead to premature compressor failure and higher operat

ing costs. If cleaning is required, be sure power to system is

shut off before attempting to clean coil.

Outdoor coil may be cleaned with brush, vacuum cleaner, or

low-pressure water (weather permitting). Do not use indus

trial strength cleaning fluids for cleaning coils. If coil has 2

rows, make coil accessible by removing the top cover and

wash out with garden hose.

A WARNING

Be careful! Coil fins are sharp. Protect hands with

gloves when cleaning or handling coil.

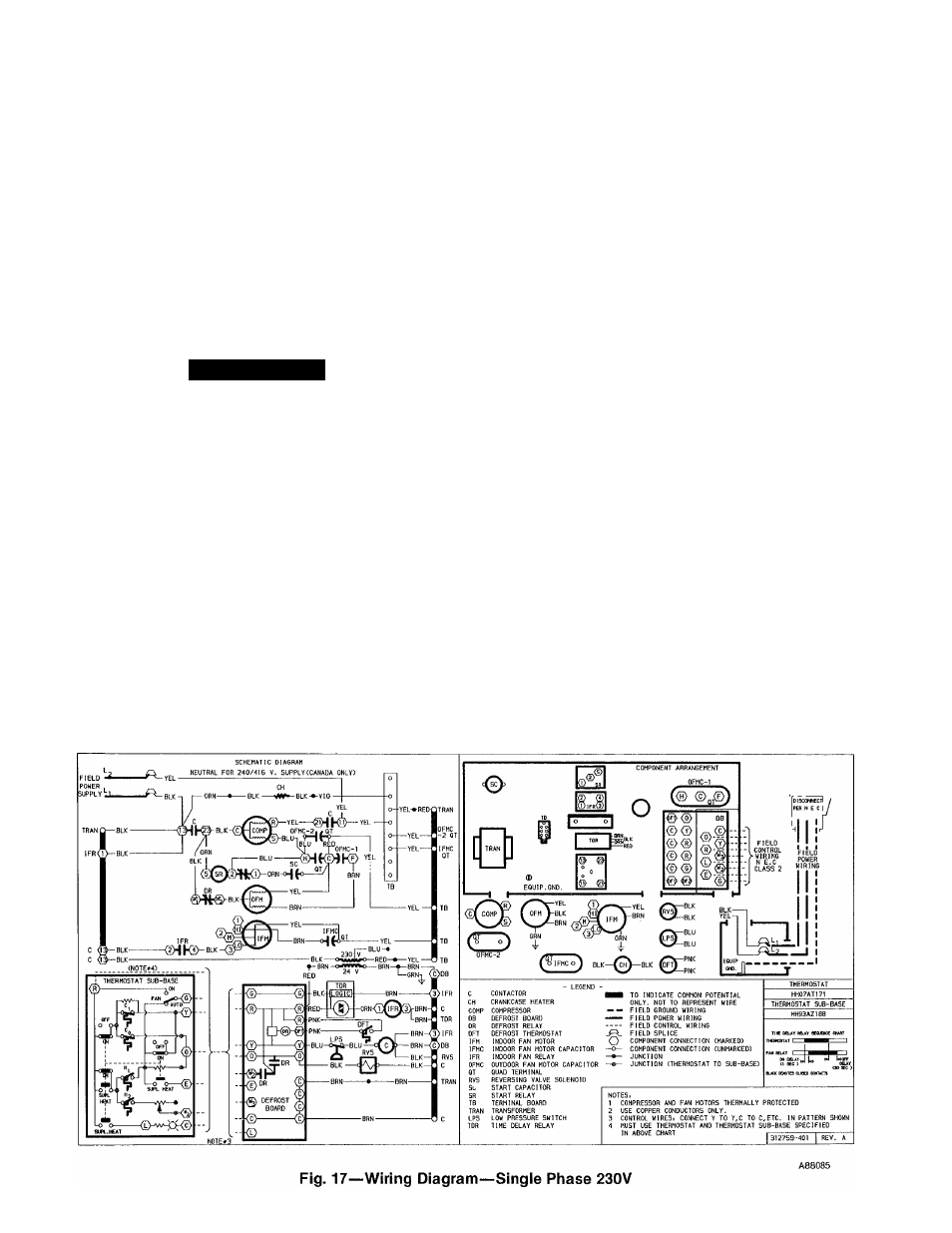

Sequence of Operation (Refer to Figs. 17, 18, 19)—

When

power is supplied to unit, transformer (TRAN) is energized.

If crankcase heater switch (CHS) is closed and outside tem

perature is below 65 F, crankcase heater (CH) will be

energized.

COOLING—On a call for cooling, thermostat makes circuit

R-0, R-Y and R-G. When room temperature rises to within 2

degrees of control setting of thermostat, circuit R-O makes,

energizing reversing vedve solenoid (RVS). Unit is now in

standby condition for cooling. As room temperature rises,

the second-stage bulb makes, allowing a circuit (R-Y)

through low-pressure switch (LPS) to contactor (C), starting

compressor (COMP) and outdoor fan motor (OFM). Circuit

R-G energizes indoor fan relay (IFR) starting indoor fan

motor (IFM).

When thermostat is satisfied, contacts open de-energizing

contactor. Indoor fan relay, compressor and motor stop.

HEATING—On a call for heat, thermostat makes circuits

R-Y and R-G. Circuit R-Y is completed, allowing circuit

through low-pressure switch (LPS) to contactor (C), starting

compressor (COMP) and outdoor fan motor (OFM). Circuit

R-G also is completed, energizing indoor fan relay (IFR) and

starting indoor fan motor (IFM).

Should room temperature continue to fall, circuit R-W is

made through second-stage thermostat bulb. If optional

electric heat package is used, a sequencer is energized bring

ing on first bank of supplemental electric heat. When ther

mostat is satisfied, contacts open, de-energizing contactor

and sequencer. Motors and heaters de-energize.

DEFROST—Defrost board (DB) is a time/temperature con

trol which includes a field-selectable time period between

check if defrost is necessary (30, 50 and 90 minutes). Elec

tronic timer and defrost cycle start only when contactor is

energized and defrost therniostat (DFT) is closed.

Defrost mode is identical to cooling mode except outdoor

fan motor stops and a bank of optional electric heat turns

on to warm air supplying the conditioned space.

14