A caution, Lubrication – Carrier 50QQ User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

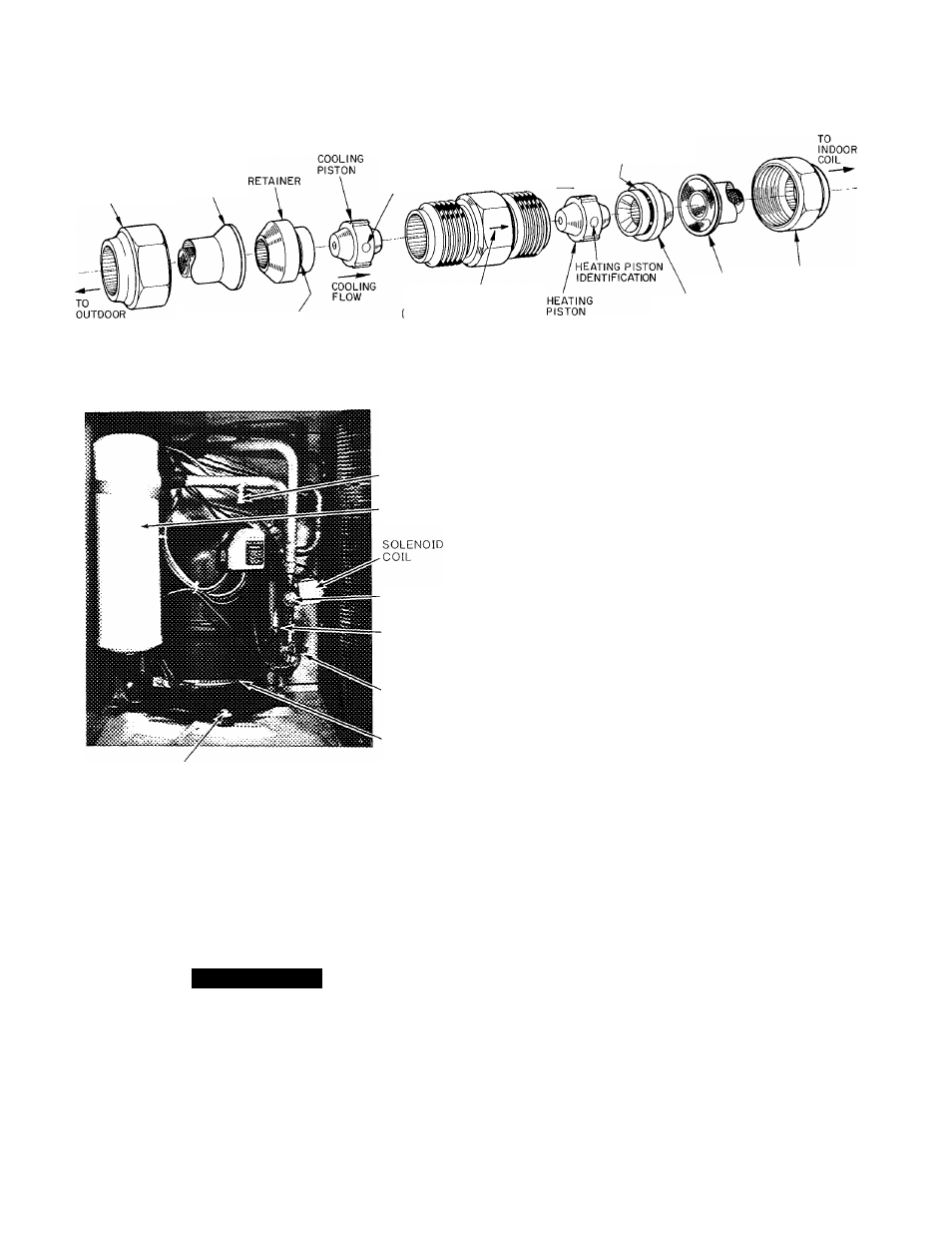

FLARE

NUT

STRAINER

COIL

COOLING PISTON

IDENTIFICATION

RUBBER 0-RING

STAMPED ARROW ON

COUPLING BODY

TOWARD INDOOR COIL)

HEATING

FLOW

RUBBER 0-RING

STRAINER

n

U

t

'^^

RETAINER

A87292

Fig. 11—Metering Device (Dual-Piston) Components

SUCTION

SCHRADER

FITTING

ACCUMULATOR

COMPRESSOR HOLDDOWN BOLT

Fig. 12—Compressor Section

REVERSING

VALVE

DISCHARGE

SCHRADER

FITTING

CRANKCASE

HEATER

SWITCH

CRANKCASE

HEATER

A87293

6. Remove wraparound crankcase heater (if used) from

compressor base.

7. Remove compressor holddown bolts and lift compres

sor out.

8. Carefully unbraze suction and discharge line piping

stubs from compressor. If oil vapor in piping stubs

ignites, use quenching cloth.

A CAUTION

Muffler may contain quemtity of oil.

9. Braze piping stubs (removed in step 8) on new

compressor.

10. Install new compressor in unit. Braze suction and dis

charge lines to compressor piping stubs (at points

where cut, step 5) using field-supplied copper cou

plings. Ensure compressor holddown bolts are in place.

Connect wiring.

NOTE:

Reinstall wraparound crankcase heater (if used)

on compressors.

11. Clean system. Add new suction line filter drier as

described below. Refer to Fig. 10.

NOTE:

If a compressor failure was caused by motor

winding burnout, the byproducts of the burnout must

be separated from the circulating refrigerant. This

must be done before the byproducts enter the reversing

vedve or accumulator emd render peu-ts inoperative.

Burnout byproducts can cause future system operating

problems if left in the system.

Clean the system by installing a suction line drier in

the refrigerant line where the suction gas enters the

reversing valve. During the cooling cycle, this is the

line from the indoor coil running across the top of com

pressor compartment; during heating cycle, install

drier in line between outdoor coil and reversing valve.

If possible, run unit in cooling mode when cleaning sys

tem as installation of temporary suction drier is

simplified.

For drier installation during heating cycle, cut line

between outdoor coil and reversing valve, install fit

tings and tubing, and install suction filter drier. To pro

vide protection for the reversing valve, do not place fil

ter drier between reversing valve and accumulator.

Since the suction drier works in one mode only, tempo

rarily wire the unit in the selected mode (heating or

cooling, based on suction drier location). To ensure

cooling operation only, instiJl a jumper between termi-

neds R and O on the low-voltage terminal board. For

heating operation only, remove and insulate one of the

reversing valve solenoid leads. Run unit for 48 hours

emd check oil for acidity. If satisfactory, remove suc

tion line drier. Refer to and follow procedure under

Metering Device Servicing for cleaning of pistons.

Rewire unit to normal conditions.

12. Triple-evacuate and recharge unit. See Refrigerant

Charging.

Filter Drier—

Install an accessory reversible, liquid line filter

drier assembly, following the instructions in accessory

package.

NOTE:

Follow instructions carefully as piston locations are

reversed from those shown when a filter drier is not used.

Lubrication

COMPRESSOR contains factory oil charge. Replace oil

when lost. See Table 7 for oil recharge. Use Carrier PP33-1,

Texaco Capella WF-32 or Suniso 3GS oil.

#

12