Condenser-fan adjustment {fig. 22), Belt tension adjustment, Economizer adjustment – Carrier 50HJ015 User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 8 — Alternate Drive Components Table, 50HJ024

UNIT

50HJ

MOTOR

HP

DRIVE

SOURCE

FAN

RPM

MOTOR

SHEAVE DATUM

DIMENSION*

(in.)

MOTOR

SHEAVE

PART NO.t

BLOWER

SHEAVE DATUM

DIMENSION*

(in.)

BLOWER

SHEAVE

PART NO.t

BELT

PART NO.t

7

V

2

Field

1181

5.6

BK62

8.4

BK90

BX50

024

71/2

Field

1244

5.9

BK65

8,4

BK90

BX51

Vh

Factory

1287

6 1

BK67

84

BK90

BX51

7'M

Field

1379

6.6

BK72

8.4

BK90

BX52

i

LEGEND

MPTA

— Mechanical Power Transmission Association

RMA

— Rubber Manufacturers’ Association

‘Datum dimension is equal to the old pitch diameter per RMA/MPTA

Standard IP20-1977. To convert to new pitch diameter per RMA/

Belt Tension Adjustment

— To adjust belt tension:

1. Loosen fan motor bolts.

2. a. 015 units:

Move motor mounting plate up or down for proper

belt tension ('/2 in, deflection with one finger),

b. 024 units;

Turn motor jacking bolt to move motor mounting plate

up or down for proper belt tension (Ys in. deflection

at midspan with one finger [9 lb force]).

3. Tighten nuts.

4. Adjust bolts and nut on mounting plate to secure motor

in fixed position.

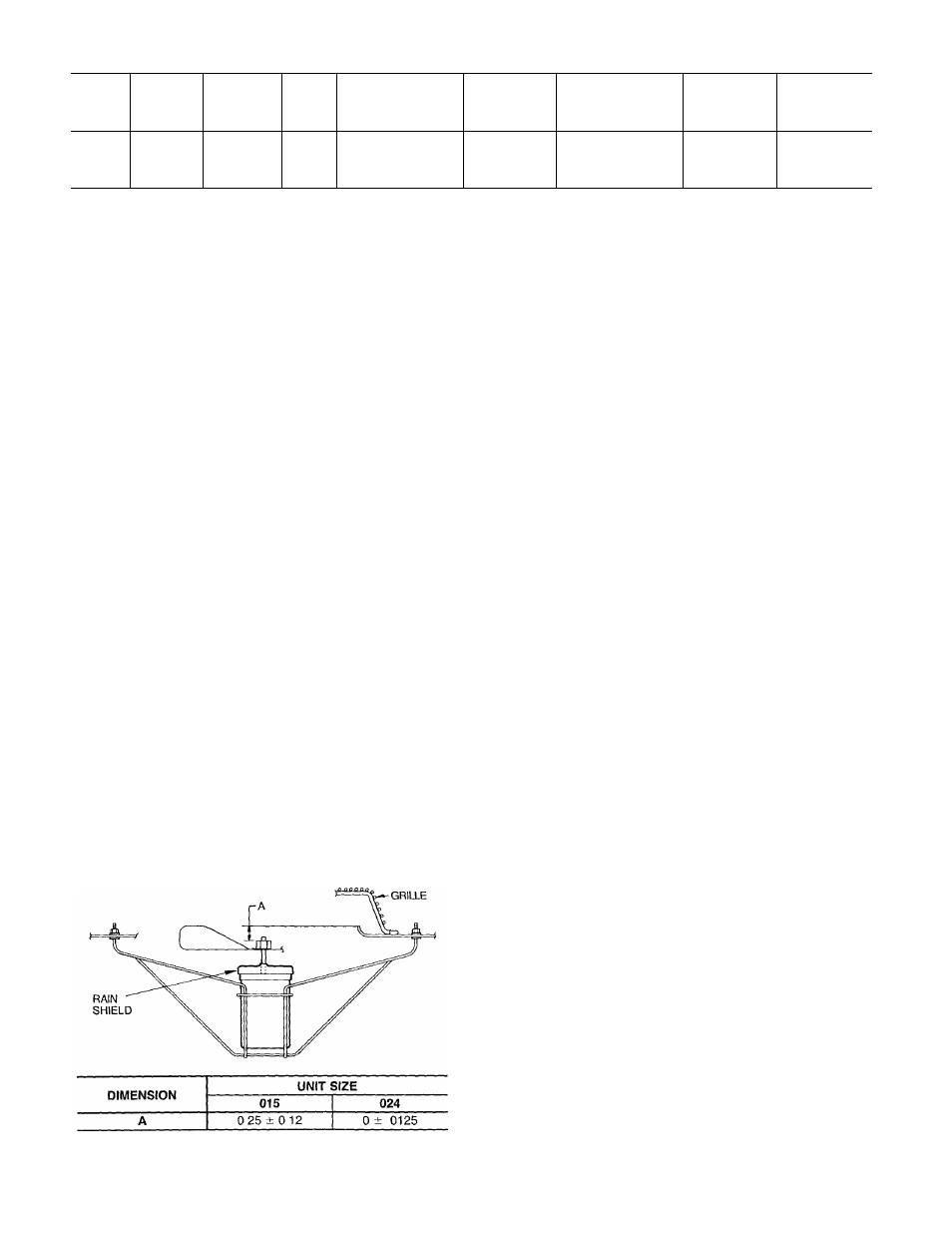

Condenser-Fan Adjustment {Fig. 22)

1. Shut off unit power supply.

2. Remove fan top-grille assembly and loosen fan hub screws.

3. Adjust fan height on unit, using a straightedge placed

across the fan orifice.

4. Tighten setscrews and replace rubber hubcap to prevent

hub from rusting to motor shaft.

5. Fill hub recess with permagum if rubber hubcap is

missing.

Economizer Adjustment

— Refer to Tables 9 and

10 for economizer checkout procedures. Make certain the

outdoor-air damper is fully closed and the return-air damper

is fully open before completing the following steps.

1. Turn on power to the unit.

2. Turn the thermostat fan switch to the ON position. The

damper will go to the vent position.

3. Adjust the vent position with the minimum position ad

justment on the economizer control module. See

Fig. 14.

Fig. 22 — Condenser-Fan Adjustment

MPTA Standard IP20-1988, add 0.3 in. to the sheave datum

dimension.

tPart numbers for motor sheave, blower sheave, and belt are Brown

ing Catalog part numbers. The motor sheaves have Browning fixed

bore sheaves supplied with factory drive package.

4. Set the system selector switch to COOL position and

set the cooling temperature selector to its lowest

setting.

NOTE: The cooling mode may also be simulated by remov

ing the thermostat wires from terminals Y1 and Y2 and in

stalling a jumper between terminals R and Y1. Refer to unit

label diagram for terminal locations.

5. Set the outdoor-air thermostat (OAT) located in the econo

mizer section of the unit to 75 F.

6. If the outdoor temperature is below 75 F, the econo

mizer will control the mixed air with the mixed-air sen

sor. If the outdoor air is above 75 F, place a jumper

around the contacts of the OAT

7. Jumper terminal T to terminal T1 on the module (see

Fig. 14). The economizer will go to the full open

position. The outdoor-air damper will go to the full open

position, and the return-air damper will go to the full

closed position.

8. Adjust mechanical linkage, if necessary, for correct po

sitioning. It may be necessary to remove the filters to

adjust the linkage.

9. Remove the jumper from around the contacts of the

OAT if installed in Step 6. Remove the jumper from

terminals T and T1 installed in Step 7.

10. If the cooling mode was simulated to operate the unit

in Step 4, remove the jumper and reconnect the ther

mostat wires to terminals Y1 and Y2.

Power Failure — Dampers have a spring return In event

of power failure, dampers will return to fully closed posi

tion until power is restored. Do not manually operate damper

motor.

Refrigerant Charge — Amount of refrigerant charge

is listed on unit nameplate and in Table 1. Refer to Carrier

GTAC II; Module 5; Charging, Recovery, Recycling, and

Reclamation section for charging methods and procedures.

Unit panels must be in place when unit is operating dur

ing charging procedure.

NO CHARGE — Use standard evacuating techniques.

After evacuating system, weigh in the specified amount of

refrigerant (refer to Table 1).

LOW CHARGE COOLING - Using appropriate cooling

charging chart (see Fig. 23 and 24), add refrigerant until

conditions of the chart are met. Note that charging charts

are different from those normally used. Charts are based on

charging units to correct superheat for various operating con

ditions. An accurate pressure gage and temperature sensing

device are required. Connect temperature sensing device to

service port on suction line and insulate it so that outdoor

ambient temperature does not affect reading. Indoor-air cfm

must be within normal operating range of unit.

14