Carrier 30GA User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

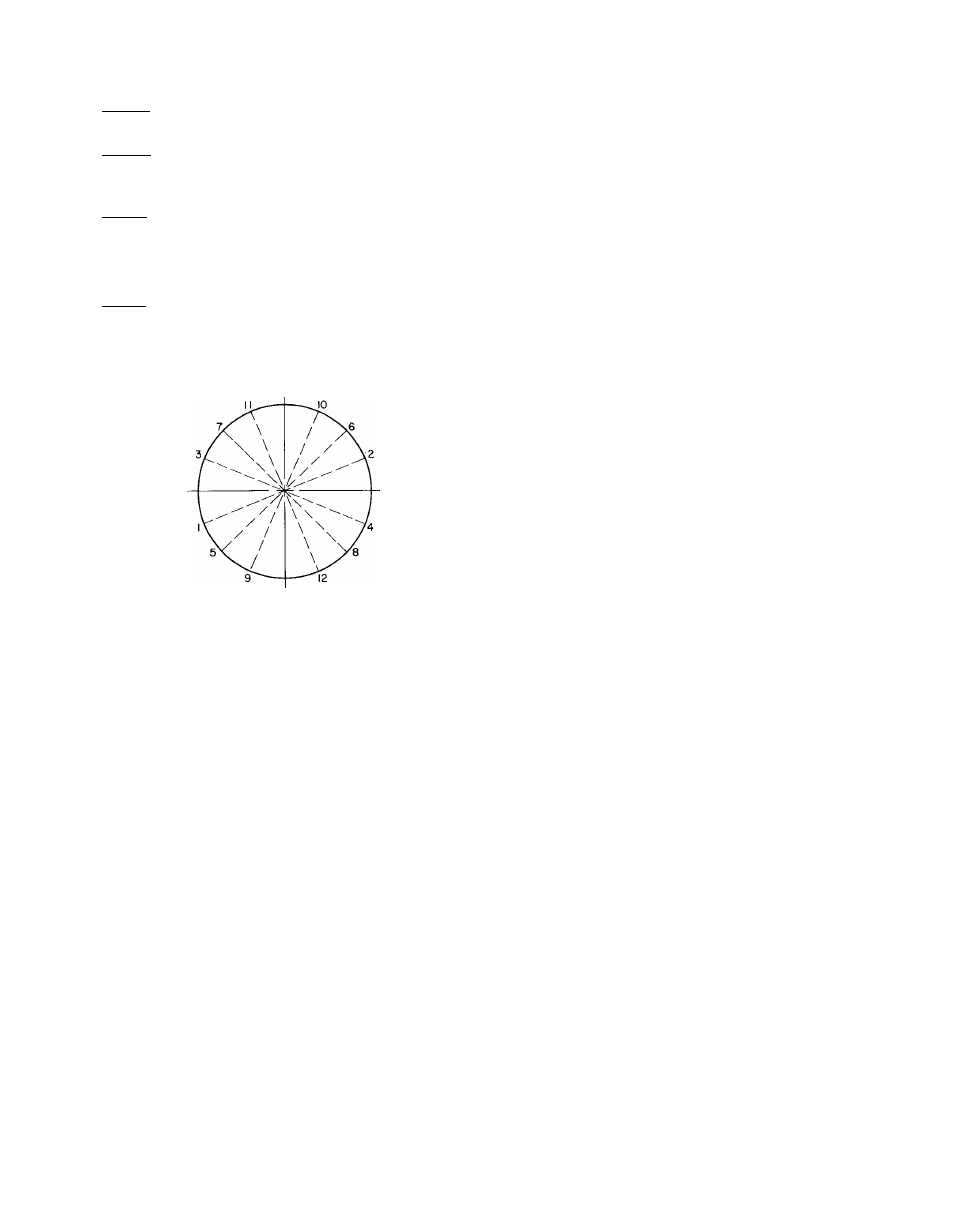

BOLT TIGHTENING SEQUENCE (See Fig. 6)

Step 1 — Tighten moderately (without torquing)

all the flange bolts in the sequence shown.

Step 2 — Tighten moderately (without torquing)

the hex nuts on the center studs (no specified

sequence).

Step 3 — Repeat Step 1, tightening the bolts to the

specified torque.

Step 4 ~ Repeat Step 2, tightening the nuts to the

specified torque.

Step 5 — Not less than one hour later, retighten the

center stud nuts to the specified torque.

TOP

Fig. 6 — Tightening Sequence, Cooler Head Bolts

Oil Charge

— Compressor is factory charged with

oil. Each 30GA020 unit has 14 pints of oil; each

30GA025 and 030 unit has 19 pints. When addi

tional oil or a complete charge is required, use only

Carrier approved compressor oil

Sun Oil Company..................................... Suniso 3GS

Texaco, Inc................................ Capella WFI-32-150

E.I. DuPont Company...........................Zephron 150

(Synthetic)

IMPORTANT; Do not reuse drained oil or use

oil tiiat has been exposed to atmosphere. Refer

to Cssrrier Standard Sendee Teclmiques Manual,

Chapter 1, Refrigerants for procedures to add or

remove oil.

Thermostatic Expansion Valves,

one for each of

the 2 refrigerant circuits, are factory set to main

tain 6 — 7 F superheat of vapor leaving cooler to

control flow of liquid refrigerant to cooler. Super

heat can be reset but should be done only if abso

lutely necessary. The complete power head and

cage assembly can be removed for servicing with

out removing the body flange from the liquid line.

The thennostatic expansion valves have non

condensable-charge power elements.

-^Liquid Line Solenoid Valves,

one in each of the

2 refrigerant circuits, are interlocked with the

water temperature controller to shut off the flow

of refrigerant to the cooler when the water temper

ature controller (WTC) call for cooling is satisfied.

They are located immediately upstream of the

thermostatic expansion valves. With single pumpout

control, the compressor continues to run after the

WTC is satisfied and the refrigerant flow is shut off

Tliis causes pumpout of refrigerant from the cooler

and subsequent shutdown of the compressor on

low-pressure control. The compressor will not

restart until the WTC again calls for cooling.

Discharge Line Check Valve

— A check valve in the

compressor discharge line prevents migration of

refrigerant from the condenser to the compressor

during the off cycle.

Moisture-Liquid Indicator

— Clear flow of liquid

refrigerant indicates sufficient charge in system.

Bubbles indicate undercharged system or presence

of noncondensables. Moisture, measured in parts

per million (ppm), in system changes color of indi

cator. Green — moisture is below 45 ppm, char

treuse (caution) — 45 to 130, yellow (wet) — above

130. Change filter-drier cores at first sign of mois

ture in system.

IMPORTANT: Unit musí be m operation at

least 12 hours before moisture indicator can give

an accurate reading. With unit running, indicat

ing element mxist be in contact with liquid

reirigexant to give true moisture indication.

Filter-Drier

— Whenever the moisture-liquid indi

cator shows presence of moisture, replace filter-

drier core. Refer to Carrier Standard Service Tech

niques Manual, Chapter 1, Refrigerants for details

on servicing filter-driers.

Liquid Shutoff/Charging Valve

is located imme

diately ahead of filter-drier, provided with 1/4-in.

flare connection for field charging.

Compressor Protection

CIRCUIT BREAKER — Calibrated trip manual

reset, magnetic. Protects against motor overload

and locked rotor conditions.

THERMAL PROTECTOR - A sensor in the dis

charge side of the compressor reacts to excessively

high discharge temperature and shuts off the com

pressor. The high discharge temperature indicates

overtemperature in the compressor motor.

TIME GUARD® function protects compressor

against short cycling. See Sequence of Control.