Water treatment, Power supply, Power wiring – Carrier 30GA User Manual

Page 3: Table 4 — electrical data

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

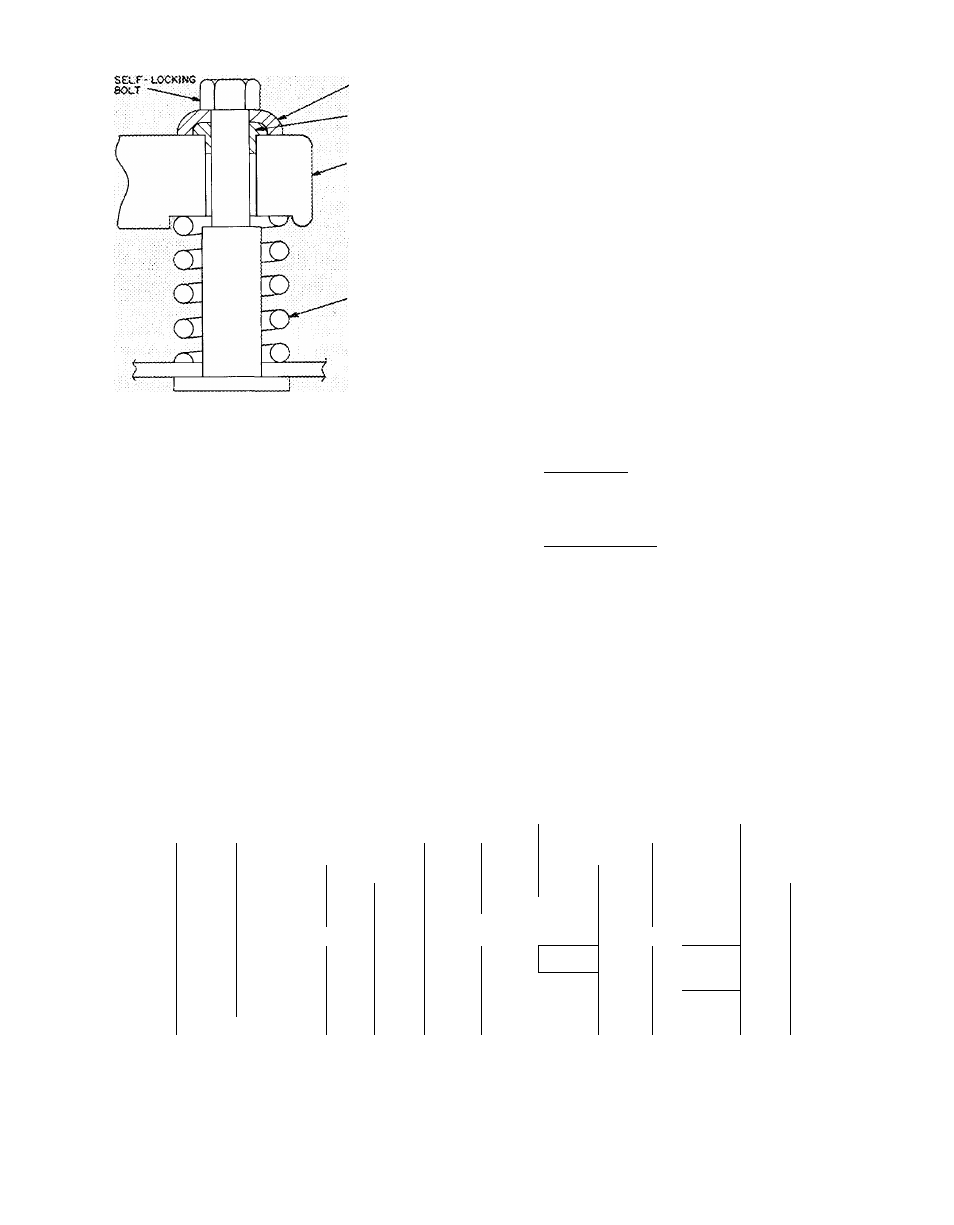

$»«je8ER Fl.AN«ED

WASHER

MEORRERE

SNUB8ER

. COMPRESSOR POOT

(SOCATJON SPRiNC

Fig. 2 — Compressor Mounting

Chilled Water and Drain Piping

— Facing the cooler

side of the unit, the return water connection is on

the left and the leaving water connection is on the

riglrt (see Fig. 1). The connections are oriented

vertically to minimize pressure losses and to facili

tate field piping for roof-mounted installations. A

means of venting air from the high point of the

field-installed piping should be provided. After

field piping is complete, wrap all piping with elec

tric heating tape and cover with suitable thickness

of closed-cell insulation. The power source for the

electric heating is the 115-volt (60-FIertz only) con

venience outlet in the bottom of the cooler section,

at compressor end. The cooler drain connection is

at compressor end (see Fig. 1). Drain piping can be

installed directly thru hole provided in cooler

section base pan. Insulate this piping, similar to

the chilled water piping, for at least one foot

from cooler.

Water Treatment

— Consult local water authority

on characteristics of water in the area and add a

recommended inliibitor to the chilled water.

Power Supply

~ Electrical characteristics of avail

able power supply must agree with unit nameplate

rating. Supply voltage must be within the limits

shown in Table 4.

IMPORTANT; Operation on improper supply

voltage or with excessive phase unbalance con-

.stitutes abuse and is not covered by Carrier

Warranty,

Power Wiring

— All power wiring must comply

with applicable local and national codes. Install a

field-supplied branch circuit disconnect switch per

NEC of a type that can be locked OFF or OPEN.

FIELD CONNECTIONS

1. Main Power — Bring wires from the disconnect

switch thru hole in bottom of unit control box

(Fig. 1) and connect to terminals LI, L2, L3 on

line side of terminal block TBl (see Fig. 3).

2. Auxiliary Power — Bring separate source power

(115-1-60) into unit as shown in Fig. 1 and Fig. 3.

This supplies power for control circuit, compres

sor crankcase heater, cooler heater and conven

ience outlet for miscellaneous auxiliary 115-volt

applications. Connect incoming wires to TB2 in

unit control box (LI toQ] and L2 to[2]). In the

auxiliary power supply, a field-supplied dis

connect with 15-amp circuit protection must be

provided to take care of crankcase heater and

cooler heater cable.

In compliance with NEC Article 440-14, the dis

connect must be located within sight of and

readily accessible from the unit.

Table 4 — Electrical Data

UNIT

COMPRESSOR

EACi-

V

d

U

s

Max

CCB

“ F

l

30GA

Mode I

Supp lied*

MCA

>"use

RLA

LRA

Fan

Min

Max

P

1 MTA

It

530

208/230

187

253

103

175

.........

76

......

^ 345

~6

S3

4.5

020

630

460

414

508

51

80

36

173

3

DO

1 9

130

575

518

632

41

60

28 6

120

3

1 40

1 6

530

208/230

187

253

145

225

100

446

6

.......

7(Г“

6.2

025

630

460

414

508

69

1 10

48

223

6

3 0

130

575

518

632

61,7

70

4d> .6

164

3

1 oT

2.4

530

208/230

187

253

168

275

\\o

506

6

83

6 2

030

630

460

414

508

72

110

ZiO

253

6

;

35

3 0

130

575

518

632

63 5

80

45

176

3

63

2 4

No.

2.3

4 6

1 9

1 6

6 6

3 0

2 4

6 6

3 0

2.4

CCB

-

FCB

-

FLA

-

LRA

-

MCA -

RLA for each motor winding is half the value shown

MTA shown is for eacli 3-pole section of the CB (each

motor winding)

Compressor Circuit Breaker

Fan Circuit Breaker (one for all fans)

Full Load Amps (fan motors)

Locked Rotor Amps

Minimum

Circuit

Amps

Complies

with

NEC,

Section

430-24

FCB

MTA

29

18

14

29

18

14

29

18

14

MTA — Must Trip Amps (factory-installed circuit breaker)

P — No of poles in CCB

RLA — Rated Load Amps (compressor)

*Units are suitable for use on electrical systems where voltage

supplied to the unit terminals is not below or above the min

and max limits shown

■fAdjacent to compressor compartment (non-cycling)

NOTE

Maximum

allowable

phase

unbalance

is

volts,

2%:

amps, 10%