Access for servicing (see fig. 5) – Carrier 30GA User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

leaks. After leaks are repaired, the system must be

dehydrated. For leak testing and dehydration pro

cedures, refer to Carrier Standard Service Tech

niques Manual, Chapter 1, Refrigerants, Sections 6

and 7.

Refrigerant Charge

— When additional or complete

field charging is required, refer to Table 1 and use

the Liquid Charging Method. Refer to Carrier

Standard Service Techniques Manual, Chapter 1,

Refrigerants, Section 8, for charging procedures.

Immediately ahead of the filter-drier is a factory-

installed liquid shutoff charging valve. A 1/4-in.

flare connection is provided for field charging.

CAUTION: Never charge liquid in to low-pressure

side of system.

Auxiliary Power Circuit

— Switch 115-1-60 field

disconnect to ON. The cooler heater is factory

wired into the control circuit. Compressor crank

case heater should be on as soon as auxiliary circuit

is energized. Allow crankcase heater to operate at

least 24 hours before starting unit, then close main

power circuit breaker.

Actual Start-Up

should be done only under super

vision of a qualified refrigeration mechanic:

1. Open any compressor and system valves that

were closed during charging.

2. Turn control circuit toggle switch to ON.

3. Push control reset button and chilled water

safety thermostat reset button to ensure circuit

operation.

4. Be sure all safety devices are satisfied.

^ 5. Check to see that the leaving chilled water

temperature agrees with the dial setting on the

temperature controller. If it is not the same as

the dial setting, the variation can be compensated

by shifting the control point slightly to obtain

the proper leaving chilled water temperature.

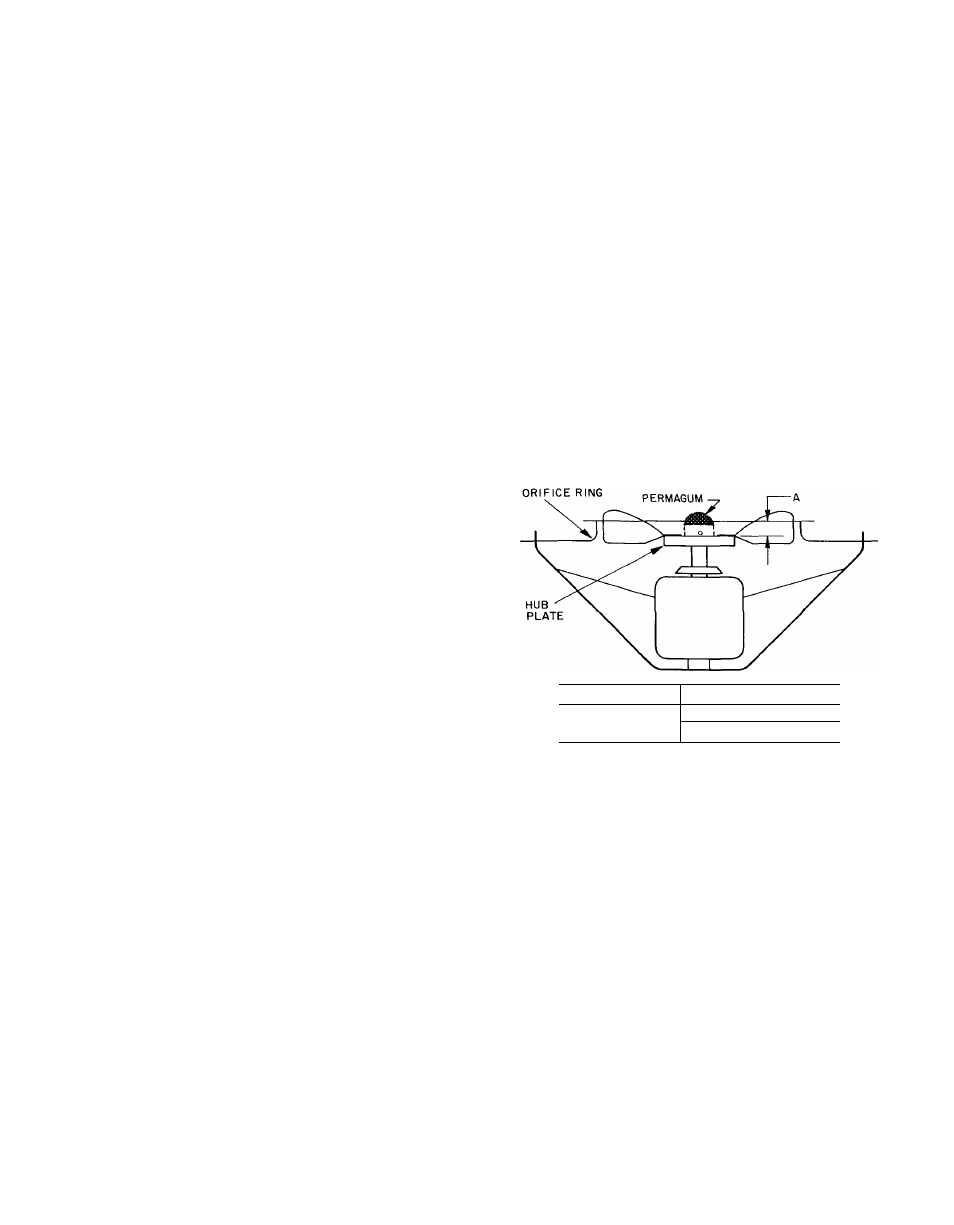

Access for Servicing (See Fig. 5)

UNIT CONTROL BOX has a gasketed removable

outer cover held on with thumb screws. An inner

panel is hinged and fastened with 2 screws. When

the inner cover is closed, the following components

are accessible; compressor and fan circuit breakers,

control circuit reset buttons, control circuit ON-

OFF switch, water safety thermostat reset button

and chilled water temperature controller set point

adjustment.

COMPRESSOR SECTION Removable top cover

and quick-access side and front panels permit ser

vicing without disturbing the condenser and fans.

In this section are the replaceable-core filter-drier,

liquid line shutoff charging valve, and moisture-

liquid indicator.

CONDENSER SECTION — Each fan motor is

clamped in a formed-wire mount. Each clamp con

sists of 2 formed-steel straps with 2 sets of bolts,

washers and nuts. The motor mount is supported

from the fan deck. If a fan motor is repaired or re

placed, be sure the wire fan guard is in place over

each fan before starting unit. See Fig. 4 for proper

fan adjustment. Secure fan hub on motor shaft

with 2 setscrews, which bear against the key. Be

sure Permagum is applied to exposed end of motor

shaft to ensure against moisture causing fan to rust

on shaft.

UNIT 3ÒGA

DIMENSION A (in.)

020

025-030

U

/32

;

End Fans

Fig. 4 — Fan Adjustment

COOLER SECTION -- Removable service panels

are provided at each end for general servicing. For

more extensive work on cooler, the full length

cover can be removed. If it is necessary to remove

cooler tubes or cooler, place a support under frame

at point “A” (Fig. 5) at each end and remove (2)

struts. Do not remove supports until the struts are

replaced.

Cooler Head Bolt Tightening

— If the cooler heads

are removed for any reason, use the following

torques and follow the given tightening sequence

when reassembling;

Torques — 5/8-in. diam bolts.......... 150 to 170 Ib-ft

1/2-in. diam bolts,

or nuts................... •......... 70 to 90 Ib—ft