Carrier 58DH User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

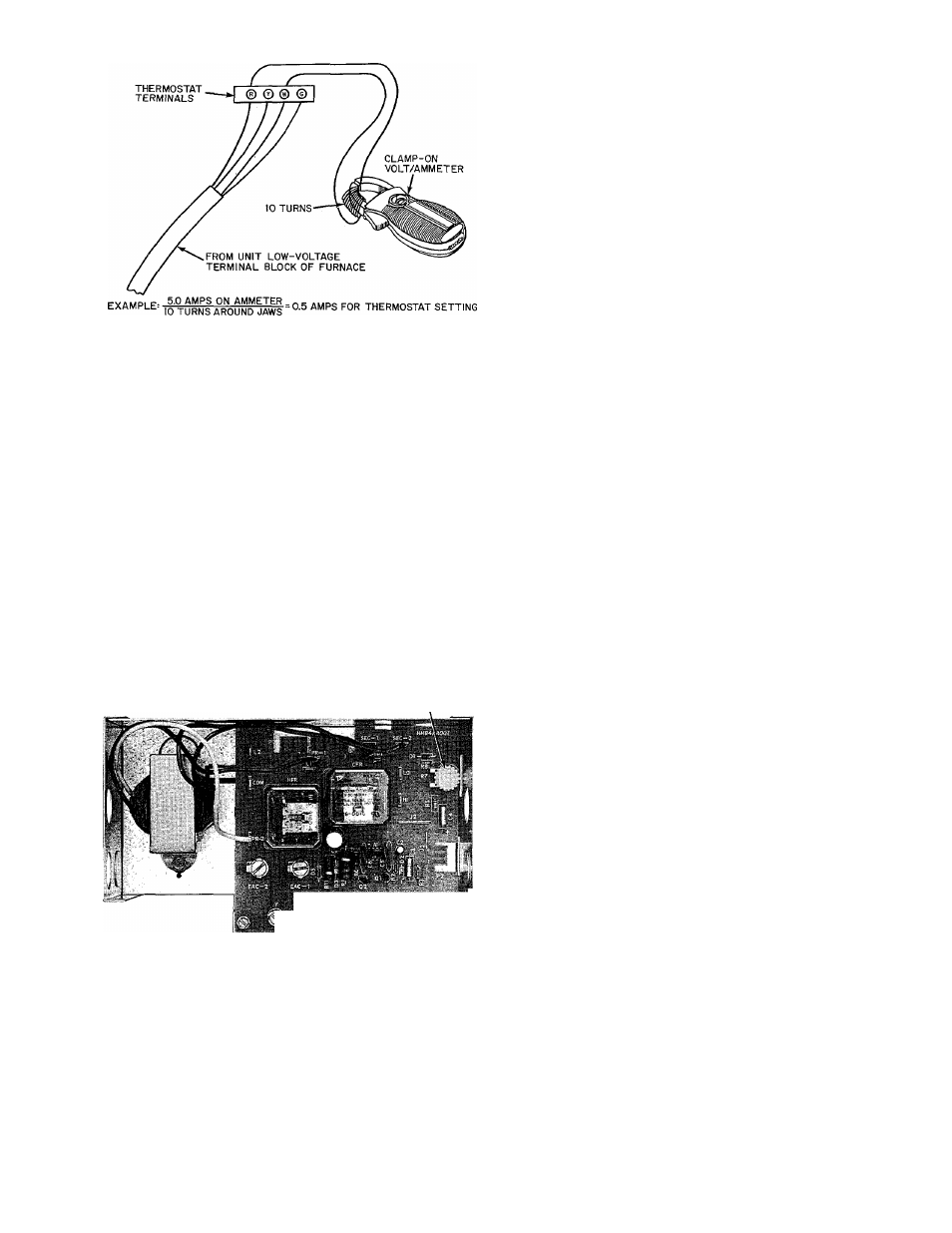

Fig. 14 — Amp Draw Check With Ammeter

BLOWER CONTROL CENTER — Furnace

features a blower control center. This aids installer

and serviceman when installing and servicing unit.

A low-voltage terminal board is marked for easy

connection of field wiring. See Fig. 15.

Main furnace control box features an adjustable

blower-off timing device. Off-timing delay can be

varied over a range of 90 — 240 seconds by turning

off-timing adjustment control in direction indicated

on label attached to side of control box. After a

change in adjustment, time-delay circuit must be

energized at least 4 minutes. This saturates solid-

state circuit so that the off-time delay will be same as

during normal furnace operation. Off-timing adjust

ment is set at factory for delay of approximately

240 seconds. See Fig. 15.

BLOWER OFF-TIME

ADJUSTMENT CONTROL

** ' I? -4' 9 Z

V, ¿J., ^ I*» "4' “s ' c

* »

Fig. 15 — Blower Control Center

2. Wall thermostat calls for heat, closing R and W

circuit. This closed circuit supplies power to

24-volt safety circuit containing limit switch 7 H1,

fusible link lie, manual reset draft safeguard

switch 7H2, and manual reset auxiliary switch

7H3.

3. Simultaneously, PICK coil of gas valve 5F, spark

generator 6F, and inducer-motor relay coil 2D

are energized. Inducer-motor relay contacts 2D

in the 115-volt circuit close, starting inducer

blower motor 3A. Also, another set of contacts

in inducer-motor relay 2D closes in 24-volt

circuit, and locks in inducer-motor relay coil 2D.

Coil is locked in until R and W circuit or safety

circuit opens.

4. When PICK coil of gas valve 5F is energized,

gas flows to pilot. Pilot gas is ignited by a spark

produced by spark generator 6F. Simultaneously,

inducer motor 3A comes up to speed, actuating

flow sensing switch 7V, energizing HOLD coil

of gas valve 5F. PICK coil of gas valve 5F and

spark generator 6F are de-energized when con

tacts of pilot-flame sensing switch 6H move from

normally closed position, breaking circuit to

PICK coil and spark generator. In approximately

50 to 60 seconds normally open pilot-flame

sensing contacts close, making circuit to MGV

(Main Operator) of gas valve 5F. Gas valve 5F

opens in approximately 10 seconds allowing gas

flow to main burners, which are ignited by pilot

6H. Simultaneously, time-delay circuit IIL in

blower control center is energized. Approxi

mately 50 seconds after gas valve 5F opens,

heating relay coil 2E is de-energized, which closes

the 120-volt contacts of heating relay 2E, starting

blower motor 3D on its heating speed.

5. When thermostat is satisfied, circuit between

R and W is broken, de-energizing gas valve 5F,

inducer motor relay 2D, and solid-state time-

delay circuit on printed-circuit board. Gas flow

stops immediately to pilot and main burners.

After approximately 90 — 240 seconds, depend

ing on off-time adjustment setting, heat relay 2E

is energized and blower motor 3D stops.

NOTE; After brief interruption of either electric or

gas supply, furnace will not resume operation until

contacts of pilot-flame sensing switch 6H move from

normally open to normally closed position.

Sequence of Operation

— Refer to wiring

diagram. Fig. 13.

HEATING CYCLE

1. When blower door is in place, 115 volts is sup

plied through blower door interlock switch 9G.

Transformer lA is energized, supplying 24 volts

to heating blower relay coil 2E, which opens

normally closed blower relay contacts 2E in

low-speed circuit of blower motor 3D.

COOLING CYCLE

1. Wall thermostat calls for cooling.

2. The R, G, and Y circuits are energized. Simul

taneously, R and Y circuit starts outdoor con

densing unit, and R and G circuit energizes

cooling relay coil 2F, which closes normally open

contacts 2F, energizing cooling speed winding of

motor 3D and opening normally closed contacts

of cooling relay 2F.