Fig. 4 — floor opening for concrete slab, Installation – Carrier 58DH User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 3 — Ratings and Performance*

FURNACE

SIZE

TEMP

RISE

RANGE (F)

HEATING

COOLING

APPROX

SHIP.

WT (lb)

INPUT

(Btuh)

CAPACITY

(Btuht)

Ext

Static

Pressure

(in. wg)

Cfm

Ext

Static

Pressure

(in. wg)

Cfm

MOTOR

HP & TYPE

OJS 100CC

43,000

3b,000

20- 50

0 12

1060

0 50

1 171

1 '3PSC

132

040-100CC

48,000

38,000

25-55

.12

1060

0.50

1 1 / 1

1 /3 PSC

132

055-1OOCC

;

6.1,UCiO

beo-'iooc'c i /1000

52,000

•10 7(J

012

1080

0.50

1157

1 3PSC

142

57,000 \ 45-75

0 12

1080

0.50

1157

1 3PSC

142

070-1 OOCC f 86,OCiO

71 000

40-70

015

1240

0 50 ' 1553

1 2 PSC

163

080-1 OOCC

95,000

77,000

45-75

0.15

1240

0.50

1553

1/2PSC

16.1

OiJO loncr

107,000

88,000 ¡ 55-85

0 20 ! 1348

0 50

1590

1 2 PSC

178

1 100 1 OOCC

119,000

98,000

60-90

_!20 I 1348

0.50

1590

1 2 PSC

178

OOlllOODC

107,000

88,000

50 80

0.20

13i)0

0 50

1929 ! 1 2PSC

188

100-100DC

119,000

■ ■ )bo"'

97,000

3-85

0 2n

1350

0.50

1929

1/2PSC

188

^ iio-ii)ocf;

106,000

40 '7Ó

0 20

193/

0 50

2010

1 2PsSC

208

120-1 OOCC

143,000

117,000

50-80

0.20"

1937

0.50

2010

1/2PSC

208

. ' I r. Models meet or exceed California low NOx requirements.

PSC — Permanent Split Capacitor

*Ratings are certified for altitudes to 2000feet. For elevations above 2000ft, reduce ratings 4% for each 1000ft above sea level.

tOetermined by U.S. Government Standard test procedures using outdoor combustion air method.

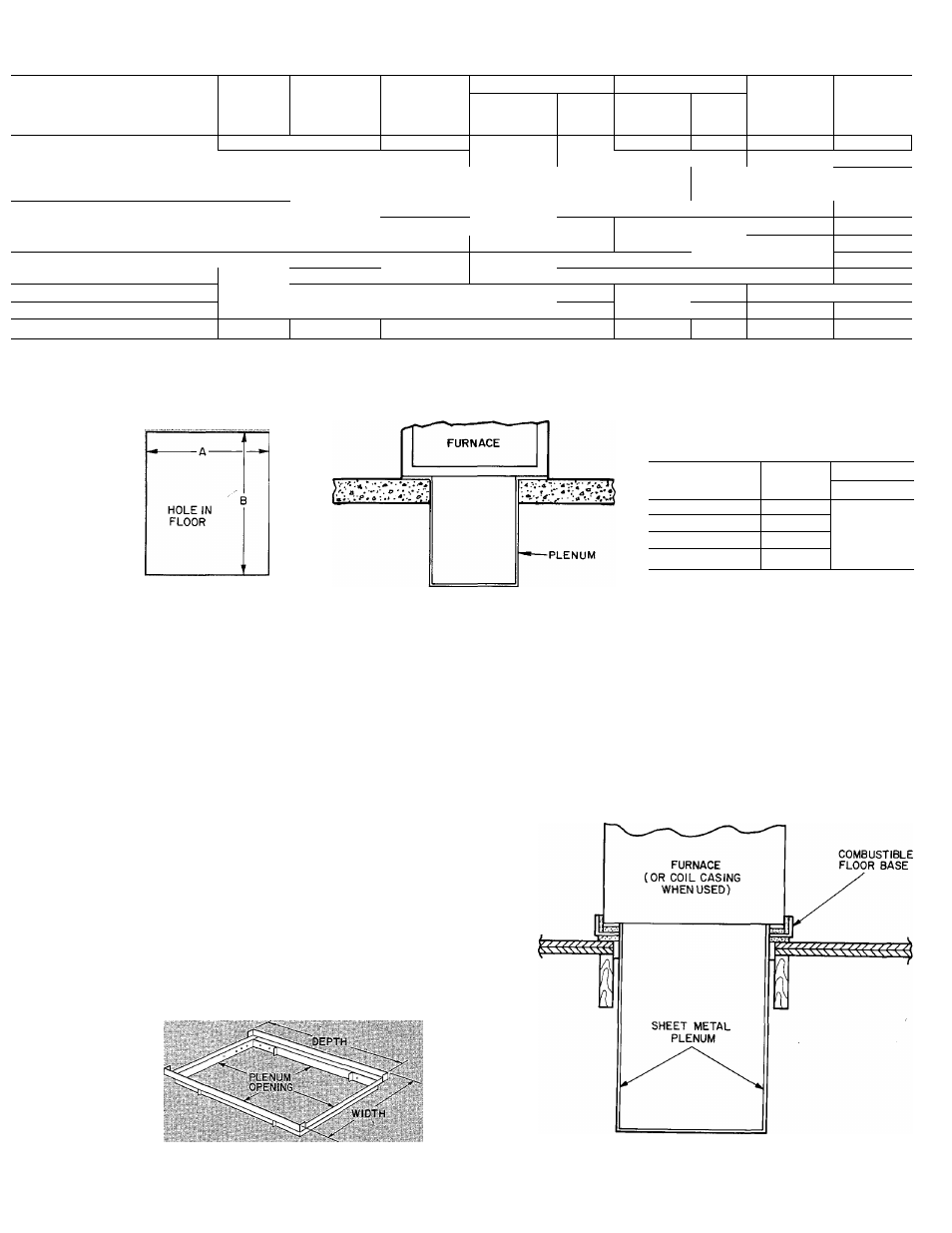

Table 4 — Opening Dimensions

(in.)

Furnace

A

B

Size

Heat-Only

035—060

13-1/8

070—lOO(CC)

16-7/16

19-5/8

090—100(00

19-7/8

110—120

23-7/16

Fig. 4 — Floor Opening

for Concrete Slab

Fig. 5 — Furnace on a Concrete

Slab

INSTALLATION

Supply-Air Plenum (Downflow)

INSTALLATION ON CONCRETE SLAB

1. See Fig. 3 for dimensions and location of supply-

air opening in furnace bottom.

2. Construct hole in floor. See Fig. 4 and Table 4.

3. Place plenum and furnace. See Fig. 5.

INSTALLATION ON COMBUSTIBLE FLOOR

1. Read installation instructions packaged with

accessory combustible floor base.

2. Cut and frame hole in floor. See Table 1 of in

stallation instructions packaged with combus

tible floor base. If this requires cutting a floor

joist, tie ends of cut joist into adjacent joists for

proper floor support.

3. Assemble and install combustible floor base per

instructions packaged with base.

4. When completed, install combustible floor base,

plenum, and furnace (or coil casing when used).

See Fig. 7.

Fig. 6 — Accessory Combustible Floor Base

Fig. 7 — Furnace, Plenum, and

Base Installed on Combustible Floor