Charging and pressure check charts – Carrier 38QF User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

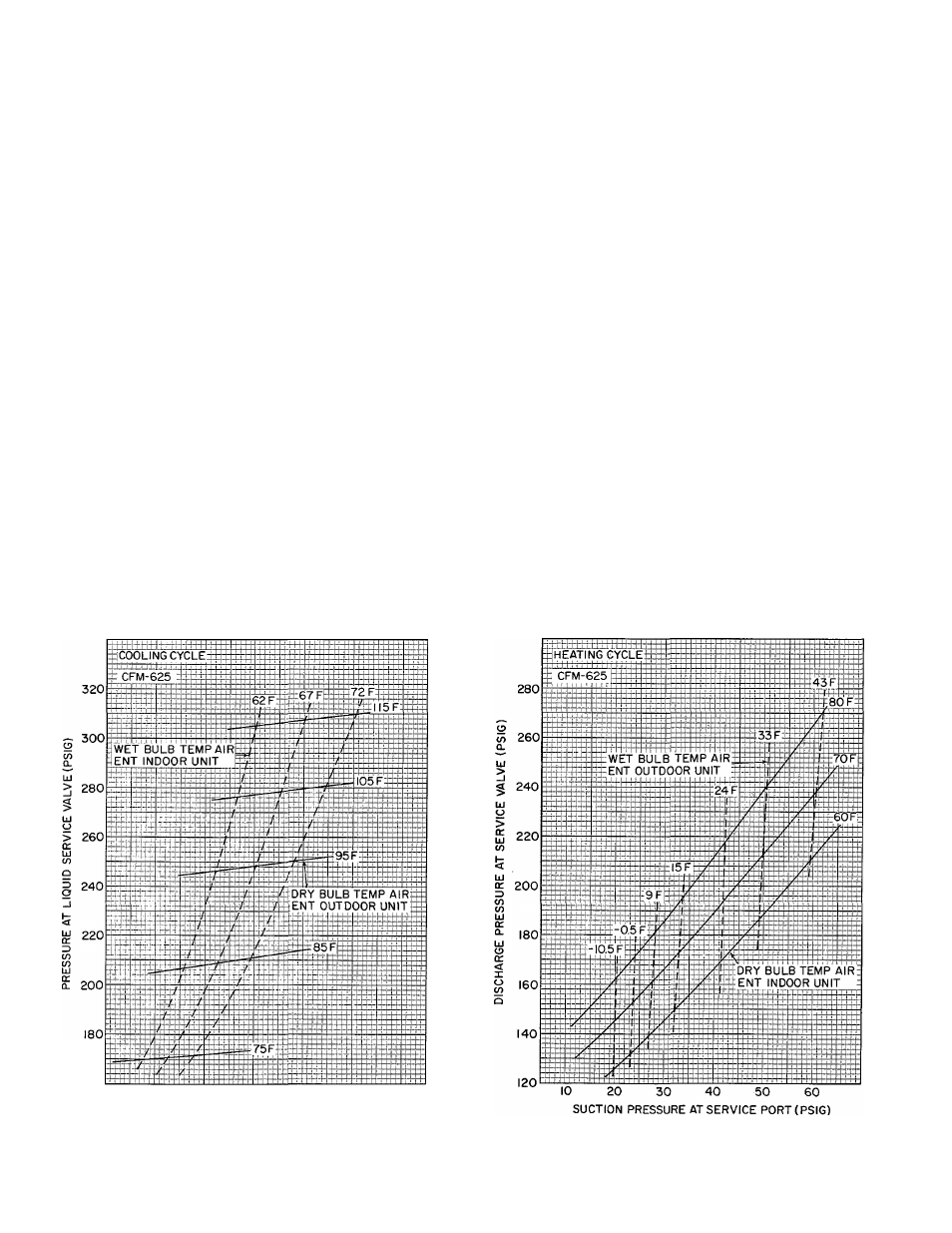

To check and/or adjust charging during cooling

season, use correct Cooling Cycle Charging Chart

(Fig. 7, 9, 11, 13, 15, 17, 19) and follow Charging

Chart Method below. The charging chart may also

be used as an alternate method of recharging system.

To check system operation during heating cycle,

use correct Heating Cycle Operation Check Chart

(Fig. 8, 10, 12, 14, 16, 18, 20).These charts indicate

whether a correct relationship exists between system

operating pressures and air temperatures entering

indoor and outdoor units. If pressure and tempera

ture lines do not intersect on chart, the system re

frigerant charge may not be correct or other system

abnormalities may exist. Do not use Operation

Check Charts to adjust refrigerant charge. Weigh

charge into system.

COOLING CYCLE CHARGING CHART

METHOD

1. Operate unit a minimum of 10 minutes before

checking

charge,

and

after

each

charge

adjustment.

2. Measure suction pressure by attaching a gage to

outdoor unit suction service port. (See Fig. 6 for

correct service port location on cooling cycle.)

3. Measure outdoor (coil inlet) air dry-bulb tem

perature with service thermometer.

4. Using a sling psychrometer, measure wet-bulb

temperature of air entering indoor unit.

5. Refer to correct Charging Chart. Locate on

curves where outdoor air dry-bulb and indoor

air wet-bulb temperature lines intersect.

6. From intersect point, project vertically down

ward to chart suction pressure line. Compare

chart suction pressure to unit suction pressure

(Step 2).

7. If unit suction pressure is lower than chart pres

sure, add refrigerant to system until chart

pressure is reached. If unit suction pressure is

higher than chart pressure, remove refrigerant

until chart pressure is reached.

Unit Single-Phase Compressors

COMPRESSORS OF THE SPLIT CAPACITOR

(PSC) TYPE require an equalized system pressure

to start. When supply voltage is within nameplate

limit and compressor does not start, give com

pressor a temporary capacitance boost. See Carrier

Standard Service Techniques Manual, Chapter 2,

for details.

W A R N I N G : C’apacilance boost or installation

of start capacitor and slaii relay should be per

formed b\ trained personnel. Improper pro

cedure could cause personal injur\ or equipment

CHARGING AND PRESSURE CHECK CHARTS

160

66 68 70 72 74 76 78 80 82 84 86 88

PRESSURE AT SUCTION SERVICE VALVE (PSIG)

Fig. 7 — 38QF018 with 40AQ018,024,

28HQ,VQ018 or 024, 40FS075 with

28HQ,VQ042 Cooling Cycle Charging Chart

Fig. 8 — 38QF018 with 40AQ018,024,

28HQ,VQ018 or 024, 40FS075 with 28HQ,

VQ042 Heating Cycle Operation Check Chart