Start-up, Fig. 4 — line power connections, Table 4 — electrical data (60 hz) – Carrier 38QF User Manual

Page 5: Heat anticipator settings for room thermo stat

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

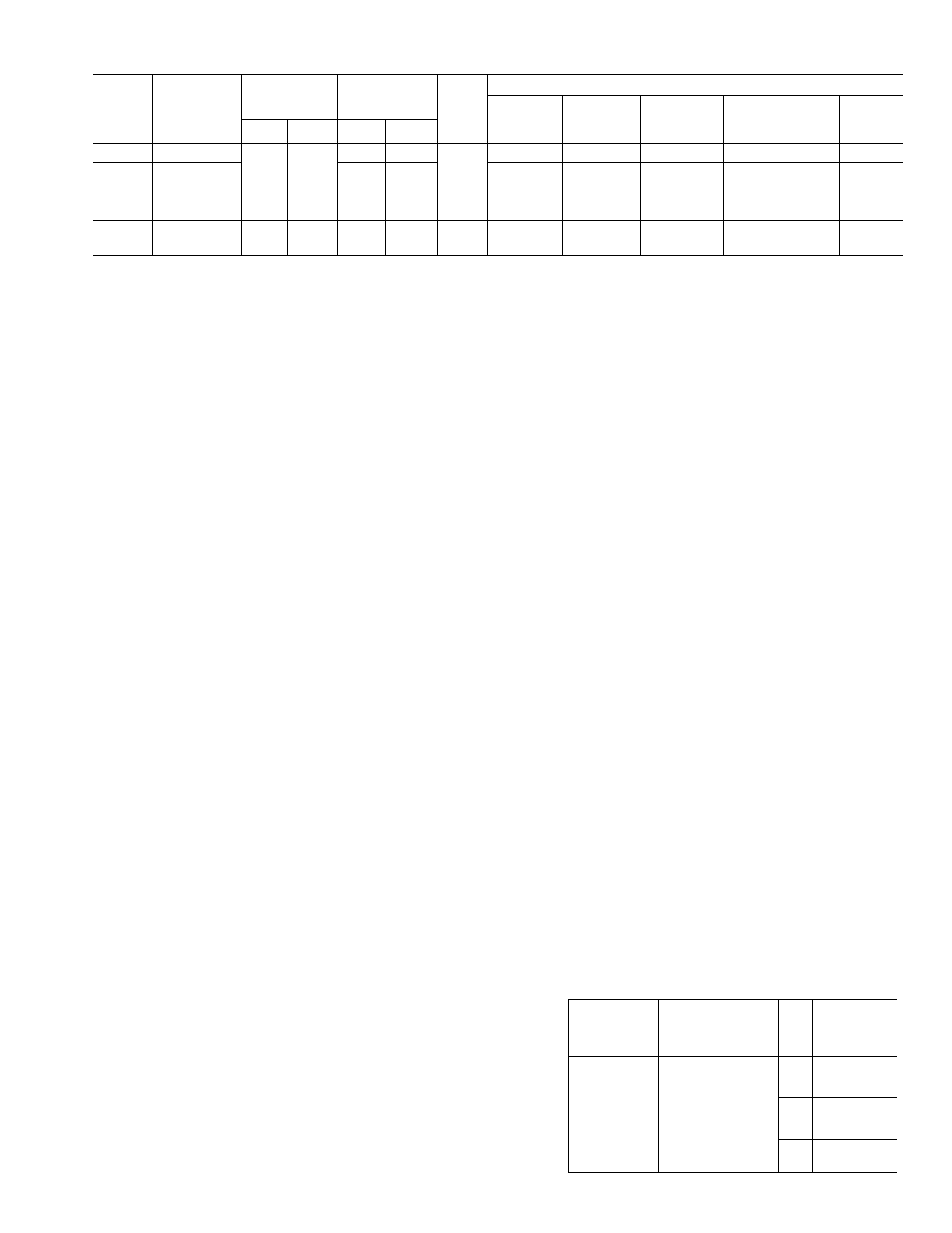

Table 4 — Electrical Data (60 Hz)

OPER

COMPR

BRANCH CIRCUIT

UNIT

38QF

V/PH

VOLTAGE*

FAN

FLA

Min Wire

Max Wire

Min Gnd

Max Fuse or

HACR Type

Ckt Bkr Amps**

MCA

Max

Min

LRA

RLA

(AWG)t

(ft)

Wire Size$

018

230/1

50

10.8

14

30

14

25

14.6

024

54

13.0

12

41

12

30

17.3

030

208-230/1

254

197

69

17.7

1.1

10

48

10

40

23.1

036

75

16.8

10

50

10

35

22.0

042

90

20.0

10

43

10

45

26.0

048

060

230/1

254

207

101

130

21.2

28.6

1.7

10

8

39

46

10

10

45

60

28.1

37.5

AWG — American Wire Gage

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

RLA — Rated Load Amps

*Permissible limits of the voltage range at which the unit will

operate satisfactorily.

tCopper wire sizes based on 60 C. Use copper wire only.

fRequired when using nonmetallic conduit.

**Time-delay fuse

When making electrical connections, provide

clearance at unit for refrigerant piping connections.

See Table 4 for recommended wire and fuse sizes.

INSTALL A BRANCH CIRCUIT DISCONNECT

PER NEC of adequate size to handle unit starting

current. Provide a separate disconnect for outdoor

unit, indoor unit and for each accessory electric

heater circuit as required. (See Indoor Unit and

Electric Heater Installation, Start-Up and Service

Instructions.) Locate disconnect(s) within sight

from and readily accessible from the unit; per sec

tion 440-14 of National Electrical Code (NEC).

ROUTE LINE POWER LEADS INTO UNIT —

Extend leads from disconnect thru power wiring

hole provided (see Fig. 1) and into unit splice area.

Remove top cover to gain access to unit wiring.

CONNECT GROUND LEAD AND POWER

WIRING — Connect ground lead to a ground lug in

control box for safety. Then connect power wiring.

See Fig. 4. Splice line power leads to yellow and

black pigtails. Use wire nuts and tape at each con

nection. Connect unit wiring to copper wire only.

SEE INDOOR UNIT AND ELECTRIC HEATER

INSTALLATION, START-UP AND SERVICE

INSTRUCTIONS for line power wiring details. All

control wiring is shown in this booklet.

CONNECT CONTROL POWER WIRING (24 V)

— Extend wiring thru hole provided (Fig. 1) and

into low-voltage section of unit control ring.

Connect leads to control wiring terminal board as

shown in Fig. 5.

Use indoor unit transformer as 24-v supply for

system. At least a 60-va transformer is recom

mended. Carrier approved indoor units are equipped

with a 60-va transformer. See indoor unit data.

Use Carrier accessory indoor thermostat with

subbase, Table 3.

START-UP

The 38QF unit is equipped with a crankcase

heater. It is recommended that heater be energized a

minimum of 24 hours before starting unit. To ener

gize heater only, turn the thermostat to OFF posi

tion and close electrical disconnect to heat pump.

Heat Anticipator Settings for Room Thermo

stat

(HH07AT171) — Set anticipator settings for

room thermostat according to Table 5. These set

tings may be changed slightly to provide a greater

degree of comfort for a particular installation.

1 PHASE

CONN. TO -

DISCONNECT

PE.R NEC

--------------- GROUND _EAD-|(^ GROUNDING LUG

-BLK-------------

.<1

Splicii Cfjnnpctions

_______Field '.Virinq

_______ Fditory Wiiinq

I-PHASE

rCND UNIT

Fig. 4 — Line Power Connections

Table 5 — Thermostat Anticipator Settings

UNIT

38QF

018

024

030

036

042

048

060

FIRST-

STAGE

ANTICIPATOR

SETTING

INDOOR

UNIT WITH

ELECTRIC

HEATER

HTR

KW

SECOND-

STAGE

ANTICIPATOR

SETTINGS

Fixed

40AQ Fan Coil

with 40AQ Htrs

or 40QB/QH Fan Coil

with 40QB Htrs

5.0

7.5

10.0

.25

15.0

20.0

25.0

.50

30.0

34.0

.75