Service – Carrier 38QF User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MOUNT OUTDOOR THERMOSTAT on control

ring, to the left of the low-voltage control connec

tion. See Fig. 1.

Attach brackets with short sheet metal screws to

avoid contact with coil. Leave capillary tube coiled

in control compartment making sure it is clear of all

electrical connections and sharp metal edges.

MOUNT SUPPLEMENTAL HEAT RELAY in

convenient location on indoor unit. Attach with

sheet metal screw.

To Start Unit

— (Make sure crankcase heater

has been energized for 24 hours.) Adjust the thermo

stat as follows:

1. Set selector switch at OFF.

2. Turn on main disconnect switch(es) to indoor

and outdoor units.

3. Set fan switch as desired (ON or AUTO.).

4. Set thermostat dial at desired temperature.

5. Set selector switch at HEAT or COOL.

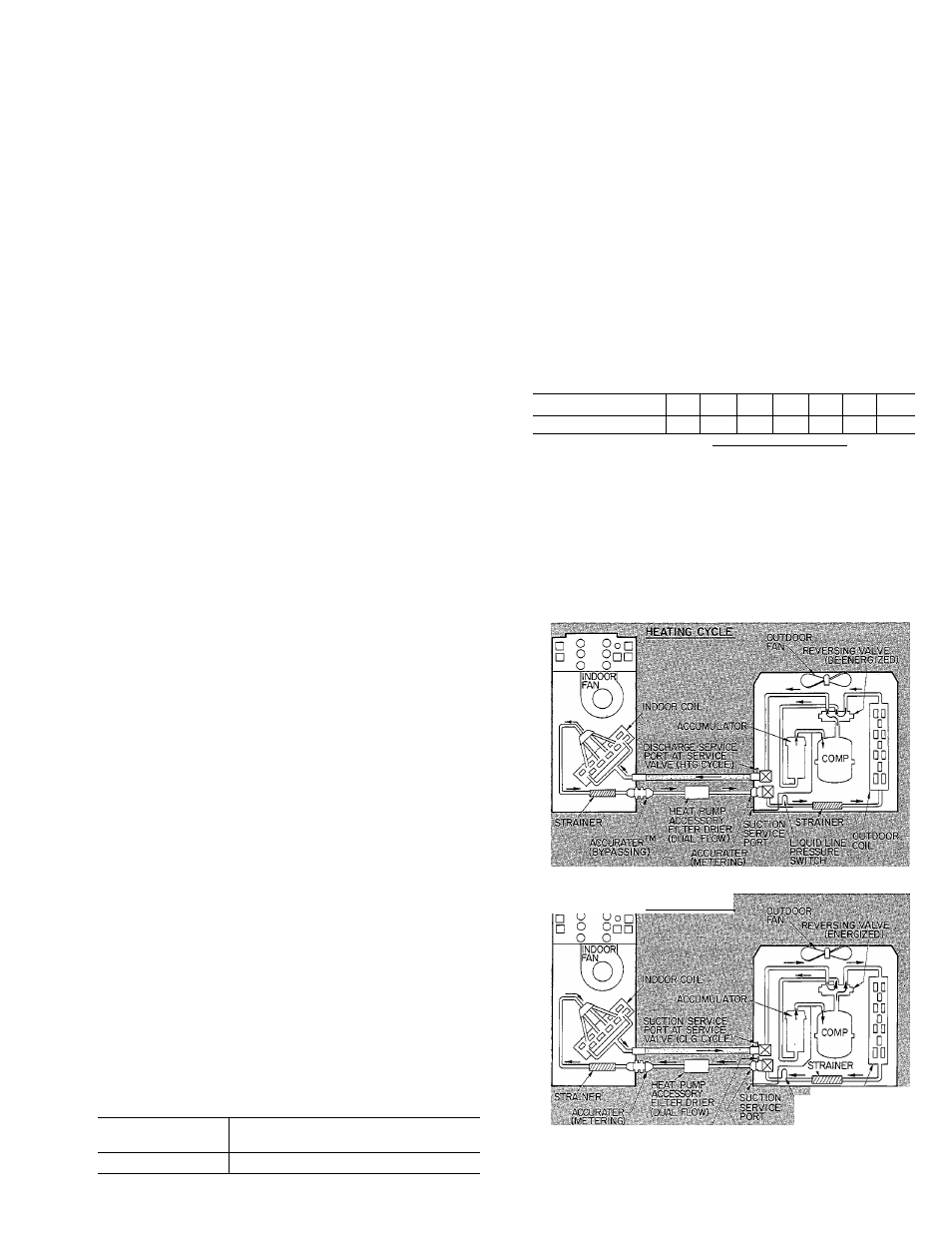

Check system refrigerant charge. See Refrigerant

Charging.

When recharging is necessa^ during heating or

cooling season, weigh in total charge indicated in

Table 6. (Charge must be weighed in during heating

season.) Remove any refrigerant remaining in

system before recharging. If system has lost com

plete charge, triple-evacuate system to 5000 microns

(29.7 in. vacuum) before recharging. Service port

connections are provided on liquid and suction line

service valves for evacuation and charging (See

Fig. 6 for correct service port location on cooling

and heating cycles.) Dial-a-charge charging cylinder

is an accurate device used to recharge systems by

weight. These cylinders are available at refrigeration

supply firms.

Table 6 — Service Data

UNIT38QF

018

024

030

036

042

048

060

R-22 CHARGE (lb)

5.7

6.1

6.7

7.4

8.7

9.3

9.8

REFRIG CONTROL

FAN

Cfm

Rpm

Diam (in.)

AccuRater™ (Bypass Type)

2400

2750

840

20

4500

26

SERVICE

C M ' l l O N : Unit has high-picssiire piping

whicli ma\ also be lu)t to touch, cncrgi/.ed elec

trical components and a rotating fan. Before

ser\icing or checking unit, be sure

all

s\stem

power is off and tubing is cool.

( \l l l ( ) \ I I I p u \ . . i l pei'oiul in, ! i \ . weai

satety glasses and glcues when handling

Do not overeharge system. \n o\erchargeean

cause compressor flooding.

Refrigerant Charging

— The 38QF units contain

correct operating charge for complete system when

connected to 28VQ, 40QB/ QH or 40AQ indoor

units with 25 ft of tubing of recommended diameter.

Charge adjustment is required on other systems.

Adjust system charge for refrigerant line lengths and

diameters that differ from 25 ft and 3/8 in. OD

(liquid line), respectively, using refrigerant weights

below. Twenty-five ft 3/8-in. OD tubing contains

14.4 oz of R-22. Add R-22 charge to system if liquid

line is over 25 ft; remove charge if liquid line is

shorter than 25 feet.

LIQUID LINE

DIAM (in.)

OUNCES OF R-22/FT LENGTH

OF LIQUID LINE

%

.58

COOLING CYCLE

piÌBilÌÌlBSB«Eip0IipÌ*®Ì5!SEBÌ

AT SERVICE VALVE (CLG CYCLE) (BYPASSING)

SWITCH

Fig. 6 — 38QF Refrigerant Flow Diagrams