A caution, Caution – Carrier 38EV024320 User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

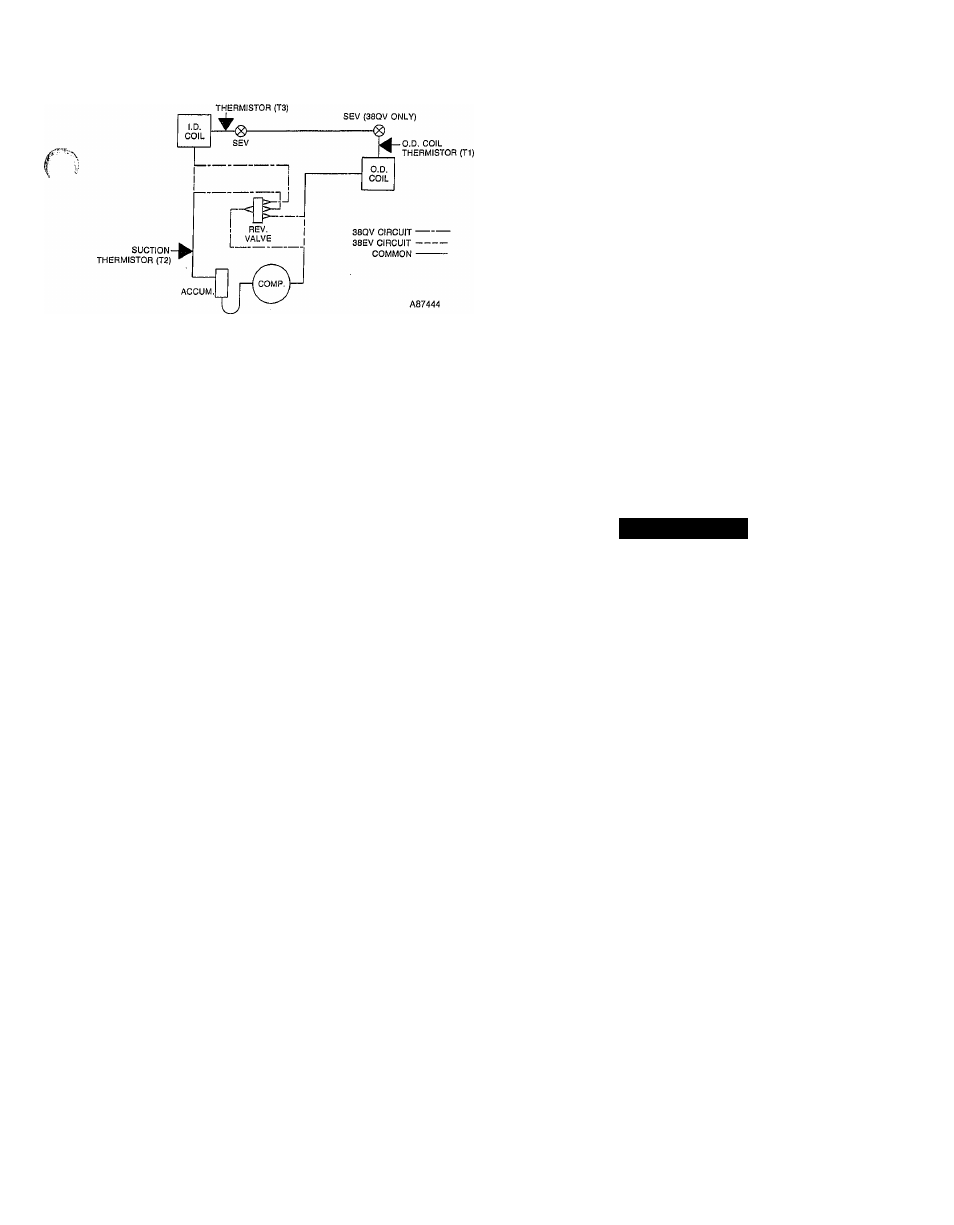

Fig. 10—Thermistor Locations

58SSB Furnace Blower Accessory—Includes the same

motor as the 40QV fan coil. Its controller and interface

board are 115 VAC versions of the fan coil components,

mounted as shown in Fig. 13.

Interface Board—serves three major functions in the

system.

Whenever gas or electric heat is energized, the interface

board takes over control of the blower from the outdoor

unit. It then forces the blower to high heating speed, which

is adjusted at the blower speed trimpot (ref. Fig. 14).

The board also contains the VVTTI thermostat power

supply.

Last of all, it acts as a connection point for input power, and

the control circuit between outdoor unit and indoor compo

nents (i.e., indoor SEV, thermistor, transformer, and blower

motor).

Blower Controller—serves a function similar to the outdoor

unit compressor inverter. It converts single-phase, 60 Hz.

power into a variable frequency output to control blower

motor speed. High and low motor speed settings are adjust

able at a 10-pin connector on the controller.

Blower Motor—is of unique design, containing a permanent

magnet rotor for superior eflBciency.

(

High Pressure Switch (HPS)—is provided for high pressure

protection of the system. It is located on the hquid line in

38EV units, and the discharge hne in 38QV units, (ref. Figs.

2 and 3). Its setting is 425 (+ -10) psig.

Low Pressure Switch (LPS)—is included to provide loss-of-

charge protection.

In 38QV heat pumps the LPS is located in the hquid line

between the outdoor coil and outdoor SEV (ref. Fig. 3). Its

setting is 5 + (+ -3) psig and provides protection in the heat

ing mode.

In 38EV coohng units, the LPS is located in the suction line

between suction service valve and accumulator (ref. Fig. 2).

Its setting is 27 (4--5) psig.

Emergency Stop Switch /EiSSj—Is used only on 38ÉV036

and 38QV036 model units. It is mounted to the top of the

scroU compressor to provide over-temperature protection,

as the scroll has no internal overload. It is located in the

safety electrical circuit in series with LPS and HPS

switches. The ESS is set to open on temperature rise at

265 + -10 deg.F and reclose at 210 + -20 deg.F.

Crankcase Heater and Switch (CH,CHS)—is connected

across the input side of the line filter and operates continu

ously except above the setting of the crankcase heater

switch (70-deg.F) which is located on the liquid hne.

The purpose of the heater is to keep the crankcase warm

during the off cycle and thus prevent dilution of the oil with

refrigerant. This assures good lubrication and prevents loss

of oil from the crankcase during startup. To energize crank

case heater, turn the indoor thermostat to OFF position and

energize electrical disconnect to the outdoor unit. If the elec

trical disconnect switch to the outside unit has been off for

an extended period of time, the crankcase heater should

be always energized for 24 hours before starting the

compressor.

INDOOR UNIT COMPONENT DESCRIPTION

40QV Fan Coils—Are essentially standard Carrier indoor

units with motor replaced by the variable speed motor and

208-230 VAC controller and interface board (ref. Figs. 11

and 12.)

A

CAUTION

An extremely hard or sharp blow to the casing or drop

ping the motor may affect motor operation due to mag

net damage.

Indoor SEV Assembly—Is provided with the 38EV or 38QV

outdoor unit. It must be mounted to indoor unit liquid con

nection during installation. The 38EV SEV assembly pro

vides two expansion orifices in parallel; a main orifice, which

is controlled by the solenoid, and a b

3q)ass orifice (See

Fig. 15).

The b

5qiass orifice is sized to meter refrigerant properly at

low compressor speeds with valve de-energized. At high

Compressor speed, the solenoid is energized, allowing paral

lel flow through a second, main orifice, sized properly for the

additional refrigerant flow needed. At intermediate com

pressor speeds, the solenoid is cycled on-off to control mid

range flow rates.

The 38QV heat pump valve functions in much the same

manner, except the fixed bypass orifice is replaced by a

standard accurator piston. This allows the capability for

non-expanded flow in the reverse direction needed in heat

pumps. This valve, with cutaway, is shown in Figs. 16

and 17. See Table 3 for piston sizes.

The SEV solenoids are energized by a 24 VDC coil, driven

directly by the main control board.

Indoor Coil Thermistor (T3)—Mounted to the SEV assem

bly, it is identical to the outdoor unit thermistors.

STEP 3—Sequence Of Operation

Startup—Once the system is properly installed or serviced,

there are two methods available to start the system and

check operation.

The first method is the “Run Test” function, which is

highly recommended for operational checkout after initial

installation or servicing. The Run Test automatically oper

ates the system in both the heat (including aux. heat) and

cool modes, thus eliminating the need to adjust the thermo

stat a number of times to force system into the desired oper

ating conditions. “Run test” operation is detailed below.