A warning – Carrier 38EV024320 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A WARNING

Unit is capable of restarting on normal thermostat

demand soon after Run Test is completed. Personal

injury can result.

(J

Normal System Startup Sequence

Apply power to indoor units via main disconnect switches.

If outdoor unit control box cover is removed, main control

board LED wiU light and extinguish after 30 seconds.

Thermostat will display HPOO (for 38QV units) or ACOO (for

38EV units).

Set up thermostat in heat, cool or automatic mode for room

temperature desired (Ref. Thermostat Operation, Trouble

shooting Section 4).

Thermostat setpoint must be 2-deg.F or more away from

room temperature for the system to initiate a startup.

(Room temperature can be displayed on thermostat by

pressing both heat setpoint adjustment buttons to right of

display simultaneously).

Startup Sequence

NOTE:

Startup delays and sequence times can be shortened

for system checkout by initiating “Speed-Up” jumper,

described below.

a) Time Guard-

Normal Ambient Startup—Mter applying power and/

or adjusting thermostat setpoint, the system will

undergo a 5-minute delay before starting. This will also

occur any time the system cycles off normally, to pre

vent unnecessary on-off cycling.

Low Ambient, Initial Startup—When outdoor tempera

tures are near or below 20-deg.F, the system will

undergo a

26-minute delay bn initial power-up only.

This allows the crankcase heater to at least partially

warm up compressor before startup.

Siartop—Compressor wffl start and ramp up to low

speed, outdoor fan wffl come on. Indoor blower will

start in a similar manner to compressor, 30 seconds

later.

b)

Low Speed

L

oc

A-I

ti

—

After starting, the' unit will lock

in at low speed for a period of 8 minutes. This is done

for the following reasons:

1. System self-diagnostics wffl monitor system condi-

tionis during this period to verify proper system

operation.

2. Allows indoor blower time to circulate and slowly

mix possibly cold ductwork air with room air, thus

avoiding erratic speed fluctuations due to unstable

thermostat readings.

c) Transition to Normal Control—li the thermostat is sat

isfied during the Srminute period at low speed, the sys

tem wffl remain at low speed for 4 more minutes and

then shut down. If not, it wffl speed up depending upon

thermostat demand. The startup sequence is complete.

“Speed-Up” Function

The “Speed-Up" jumper is a yellow jumper, similar to the

“Run Test” jumper. It’s located on the outdoor unit main

control board next to the label “Speed-Up” (ref. Fig. 5). The

function is initiated by removing and reinstalling the

jumper during the sequence period you want to eliminate.

For instance, if you want to ehminate the time guard period

before startup, wait for the LED to extinguish after power-

up. Then pull and reinstall the “Speed-Up” jumper. This

wffl shorten the respective period, (i.e., 5 minutes down to 2

minutes for the normal time guard, or 20 minutes down to 4

minutes for low ambient initial startup).

If the jumper is pulled and reinstalled during a sequence

period listed in Table 2, it wffl shorten that period as indi

cated. The speed-up function will then cancel automatically

when the next event listed in the table occurs. To shorten

subsequent sequence periods, the jumper must be initiated

again.

Table 2—Speed-Up Function

Initiate The

Jumper During

This Period

Period Wiil

Shorten From

Normal- to Speed-Up

Speed-Up Function

Will Cancel

When

—Prestart

Time Guard

5 Min.—2 min.

OR* 20 Min.—4 Min.

Compressor Starts

—Low Speed

Lock in At

Startup

8 Min.—

40-50 Seconds

Compressor Begins

Ramping Above

Low Speed, Or

Shuts Down

— Between Defrost

Periods (Beiow

32-Deg.F

Ambient)

45 Min.—4-5 Min.

(1st Defrost)

30 Min.-4 Mrs.-

3-24 Min.

(Subsequent

Defrosts)

Unit Initiates

A Defrost

—During Defrost

4-10 Min.-

24 Sec-1 Min.

Defrost Termination

*Low Ambient Initial Startup

Cooling Operation

Compressor—

During normal operation, the compressor speed will vary,

based on thermostat demand, from 2200 RPM at low speed

to 5000 RPM at high speed.

Indoor Blower-

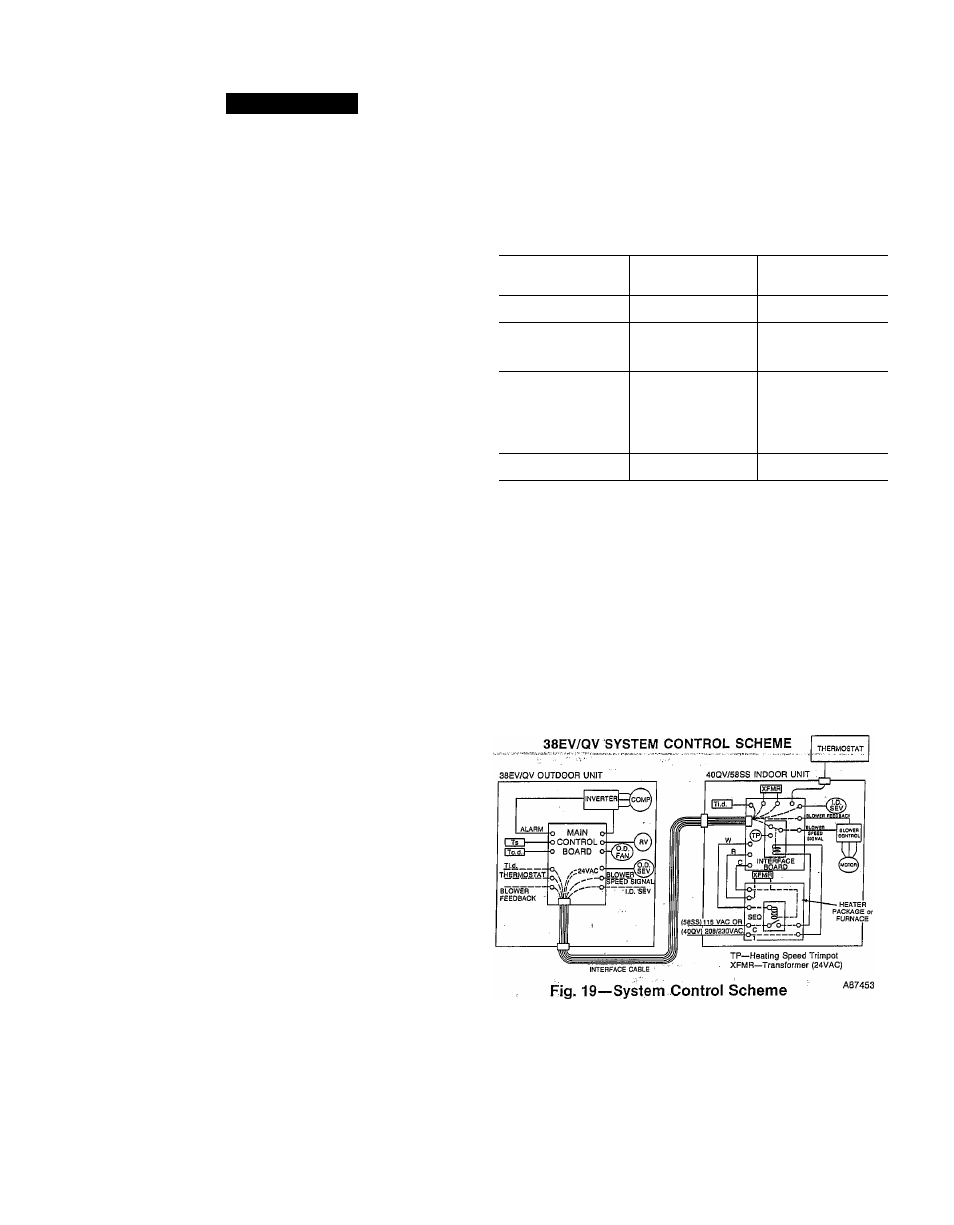

Blower speed (or airflow) wffl “track” or follow compressor

speed; i.e., when the compressor is at low speed, so is the

blower. If the compressor ramps^oTiigh.speed, the blower

ramps to high speed simultaneously. This speed signal is

sent from the outdoor unit main control board, through the

indoor unit interface board to the blower controller. (See

Fig. 19).

Outdoor Fan—

The outdoor fan cycles on-off with the compressor.

Solenoid Expansion Valves (SEV)—

In the cooling mode only, the SEV at the indoor unit is oper

ated. SEV operation “tracks” or follows compressor speed

directly. At low compressor speed operation, the solenoid

remains off and aU refrigerant flow is directed through a

bypass orifice in the valve body (38EV systems). In 38QV

systems, the bypass orifice is located in the accurator piston

(Ref. Component Description, Section 3). At high compres-