Carrier 38EV024320 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

sor speed, the solenoid is energized on continuously, allow

ing the extra refrigerant flow required through a second ori-

flce in parallel to the bypass orifice. At intermediate com

pressor speeds, the SEV is cycled on-off at different rates,

depending upon compressor speed. This rate is based on a

5-secpnd on-off period, with the on-time increasing (with

compressor speed) from zero (at low speed) to the full five

seconds on (i.e., continuous on) at high speed. For instance,

at lower speeds, the SEV is on 1 second, off 4 seconds; at

medium speed, on 2.5 seconds, off 2.5 seconds, and so on.

Proper vsllve operation can be checked by listening closely

for the “clicking’’ at the indoor SEV during intermediate

speed operation.

- --—

-----

The system will cycle on-off at low speeds at moderate^ (75-

deg.F) outdoor temperatures. It will operate continuously at

increasingly higher speeds as outdoor temperatures

increase.

Heating Operation—

38QV Systems Heat Pump

Heat pump operation is executed in the same manner as in

the coohng mode. Indoor blower speed and SEV control

“track” or follow compressor speed directly. However, in

the heat mode, only the outdoor unit SEV is operated. It is

cycled in the same pattern as cool mode control, except

cycling on-time is shortened at colder ambients, (i.e. At low

ambients, the SEV may also be cycling on-off rather than

remaining full on when the unit is at high speed).

The system will cycle on-off at low speeds during normal

operation at moderate (50-deg.F) outdoor temperatures. It

will operate continuously at increasingly higher speeds as

outdoor temperatures drop.

When outdoor temperatures drop to a point where supple

mentary heat is required, dr the optimizer function is ena

bled, electric or gas heat is initiated. Electric heat and

furnace operation are described in the following sections.

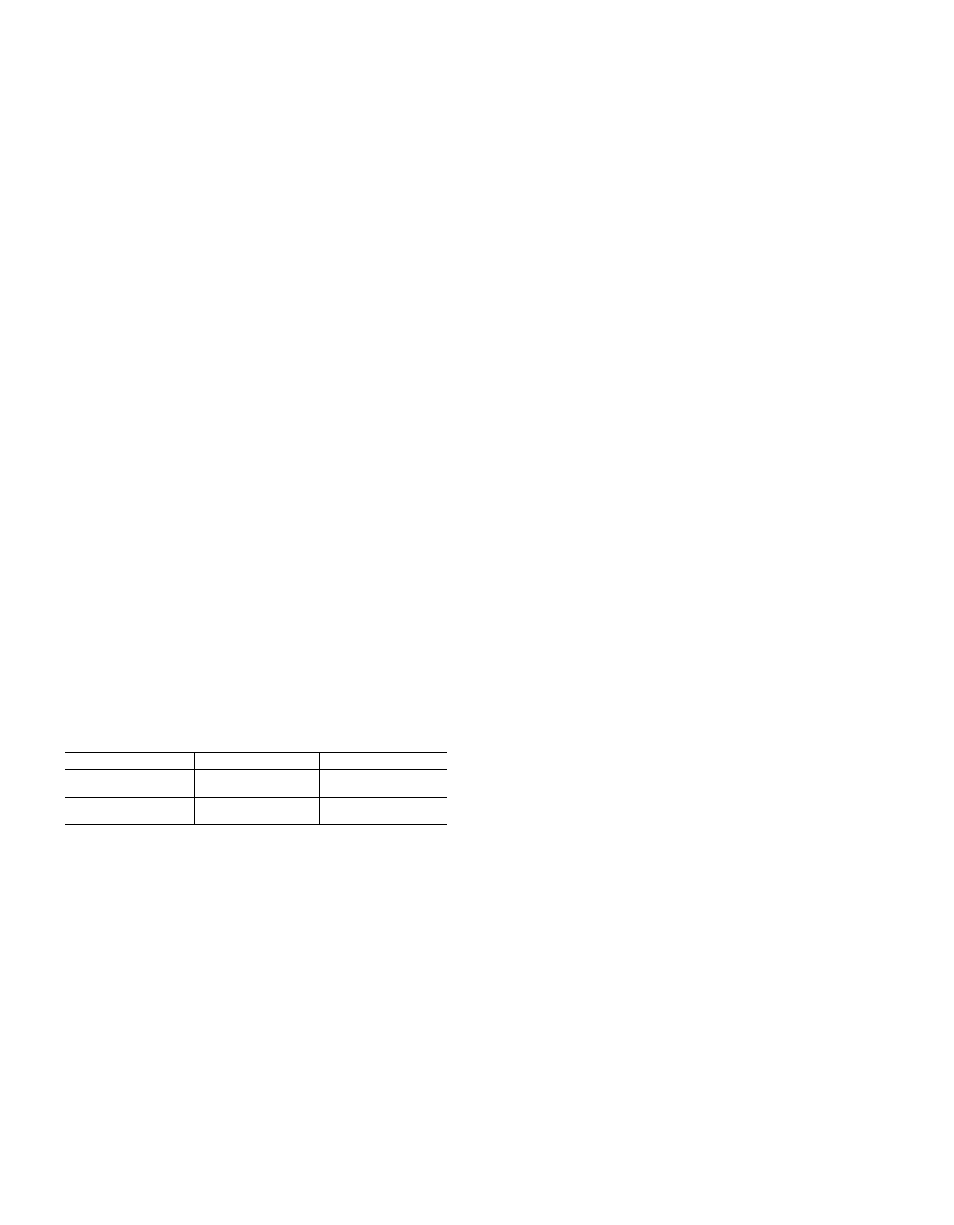

Table 3—38QV Piston Sizes

UNIT

LOCATION

■ PISTON#

38QV024

Outdoor

42

,

- - •

Indoor

49

38QV036 ,

. . '„ Outdoor ,,

. 52

. Indoor...............

63

Electric Heat Control—

(38EV and 38QV ¡Systems)

Electric heat is initiated and controlled by energizing “W”

in the same manner as in standard systems. However, since

the variable speed blower heeds a speed input signal to oper

ate, blower control is considerably different.

Blower Control—In.=a standard 'heat package, energising

‘‘W)’’ energizes the heater sequencer(s). When this is done,

the ian relay is b

3^assed-by 230V power to drive the blower

directly. Therefore, if the fan relay is faulty, the blower still

operates for safe electric heat operation.

40QV Fan Coil Units operate in a similar manner (Ref. Wir

ing Diagrams). However, instead of operating the blower

directly, this ■'230VAC power is apphed to the interface

board at terminals C and 1 (see Figs. 14 and 19). When these

terhiinals are energized by the electric heat sequencer, the

interface board relay breaks the speed signal connection

from the outdoor unit and allows the interface board to

drive the board at a speed set by the adjustable pot on the

board. ; '

When the electric heat (“W”) is cycled off, normal sequencer

operation retains blower control from the interface board

until the heaters cool down. When terminals C and 1 are de

energized by heater package, blower control reverts back to

the outdoor main control board.

Supplemental (2nd Stage) Heat—

(38QV Heat Pump/40QV

Fan Coil Systems Only)

Supplemental heat is required when the outdoor tempera

ture drops too low for the heat pump to handle the load

alone. At this point, the system begins cycling electric heat,

in addition to continuing full speed heat pump operation.

This is done by energizing heater package terminal “W.”

The heaters and blowers are controlled as described above.

A change in blower speed when the interface board takes

over control may not be noticeable, since the outdoor unit is

already operating it at high speed.

It may be noticeable if the blower heating speed trimpot is

adjusted below its maximum setting.

Heating Operation—

(38EV Cooling Systems)

and

Emergency Heat—

(38QV Heat Pump Systems)

Electric or gas heat is operated directly on thermostat

demand on 38EV systems or whenever the 38QV outdoor

unit operation is locked out due to a diagnostic problem.

The blower is controlled by the interface board as described

above. However, since the blower is not being operated by

the outdoor unit during electric heat off cycles, the blower

will cycle fuU-on-off similar to standard systems.

NOTE:

Malfunction of certain electronic control compo

nents can cause lack of Automatic Emergency Heat initia

tion. See Service & Maintenance section for corrective

servicing procedures.

The 58SSB furnace will operate as described in the litera

ture provided with it. The only difference is control of the

variable speed blower. The standard 58SSB furnace

bypasses its fan relay to lock-in blower operation when the

burner is on, just like an electric heat package.

The variable speed blower package switches blower control

to its interface board when “W” is energized, in the same

manner as described above for “Electric Heat Control.”

(The furnace interface board design is identical to that for

the 40QV fan coil, except it is a il5VAC yersioh)/

The blower will remain off for 2r3 minutes while the burner

ignites and warms the heat exchanger. The blower wUl then

start, and ramp to low speed for a short period before going

to full speed. 'When “W” is de-energized, the blower will

stay on for a short period to use the remaining heat from

theexchanger.

Supplemental (2nd Stage) and Optimizer Control—

(38QV

Heat Pump/58SSB Furnace Systems)

Unlike fan coil operation, the furnace wiU not operate simul

taneously with the heat pump. Therefore, whenever the out

door temperature drops to where the heat pump cem no

longer match the load, or the optimizer setpoint is reached,

the heat pump wfll shut down when. furnace startup is

requested (“W” is energized). At this point, the heat pump

wfll also shut down the indoor blower (except if ,the thermo

stat is in the fan-on position). The normal furnace delay of

2-3 minutes wfll then pass before the blower is cycled back

on, to allow the heat exchanger to heat up. Once the thermo

stat is satisfied by the furnace, it will cycle off. Operation

wfll alternate between furnace and heat pump, until either

the heat pump can handle the entire load, or the optimizer

setpoint is reached. If the optimizer setpoint is reached, the

heat pump wfll be locked out (a minimum of two hours) and

the furnace will cycle directly on thermostat demand.

I