Fig. 7 — high- and low-voltage connections, Start-up – Carrier 48GH User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

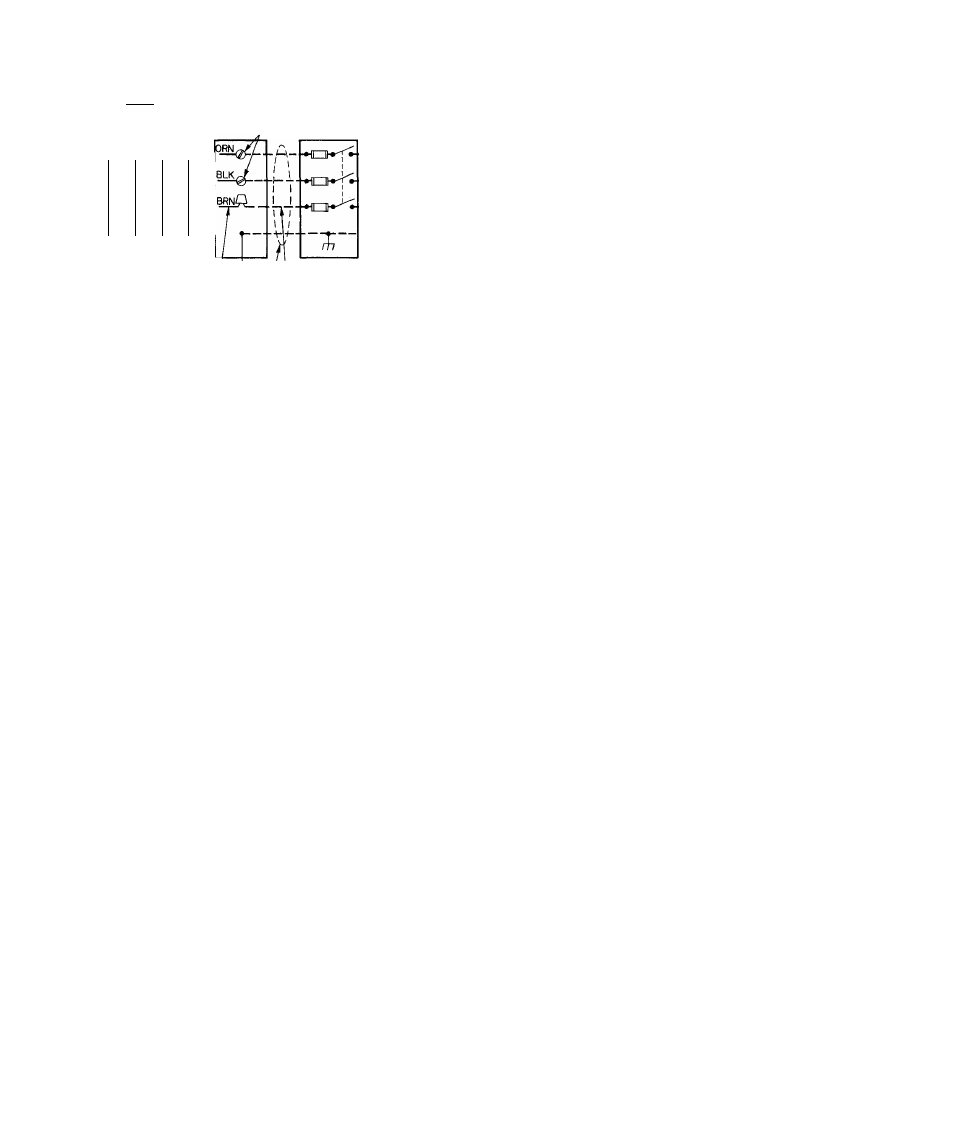

SINGLE-STAGE HEAT & COOL-MANUAL CHANGEOVER

(p ®

I FIELD

I SPLICE

CONTACTOR TERMINALS (SEE

UNIT WIRING LABEL)

b ^ ^

V]

I]

-J

3

O

>•

GÛ

a:

LOW-VOLTAGE

PIGTAIL LEADS

.POWER

I SUPPLY

CONTROL BOX I

/ | FIELD-SUPPLIED

HIGH-VOLTAGE PIGTAIL LEAD / „"gCONNECT

HIT I

FIELD-SUPPLIED CONDUIT

3-PHASE UNITS ONLY

-------FIELD LOW-VOLTAGE WIRING ■

-------FIELD HIGH-VOLTAGE WIRING ■

-FACTORY LOW-VOLTAGE WIRING

-FACTORY HIGH-VOLTAGE WIRING

NOTE;

For manual changeover applications, use thermostat part no

HH01AD042 with subbase part no HH93AZ042; or thermostat

part no. HH01AD040 with subbase part no HH93AZ040

For automatic changeover, use thermostat part no HH07AT074

with subbase part no HH93AZ096; or thermostat part no

HH10AD041 with subbase part no HH93AZ041

Fig. 7 — High- and Low-Voltage Connections

When operating Models 48GL018 thru042 single

phase units or Models 48GH036 thru 048 three-

phase units at 208 volts, disconnect orange

transformer-primary lead from contactor. See unit

wiring label and Fig. 7. Remove tape and cover

from terminal on the end of red transformer

primary lead. Save cover. Connect red lead to

contactor terminal from which orange lead was

disconnected.

Using cover removed from red lead, insulate

loose terminal on orange lead. Wrap cover with elec

trical tape so that metal terminal cannot be seen.

NOTE: For some units, the factory-wired blower-

motor speed connections may require changing for

208-volt operation to ensure adequate airflow at the

rated external static pressure. See unit wiring label.

Insulate all unused motor leads following same

procedures described for transformer leads.

LOW-VOLTAGE CONNECTIONS — Use a suit

able room thermostat as specified on unit wiring

label.

Locate room thermostat on an inside wall in space

to be conditioned where it will not be subjected to

either a cooling or heating source, or direct exposure

to sunlight. Mount thermostat 4 to 5 ft above floor.

Use No. 18 AWG color-coded, insulated (35 C

minimum) wires to make low-voltage connections

between thermostat and unit. If thermostat is

located more than 100 ft from unit (as measured

along the low-voltage wires), use No. 16 AWG

color-coded, insulated (35 C minimum) wires.

A grommeted, low-voltage inlet hole is located

in a panel adjacent to control access panel. See

Fig. 1. Run low-voltage leads from thermostat, thru

inlet hole, and to low-voltage flagged pigtail leads

that run thru a hole in bottom of unit control box.

See Fig. 6. Connect thermostat leads to the pigtail

leads as shown in Fig. 7.

HEAT ANTICIPATOR SETTING — Room ther

mostat heat anticipator must be properly adjusted

to ensure proper heating performance. Set heat

anticipator to approximately 0.85 amps. Use an

ammeter to determine exact required setting.

Failure to make a proper heat anticipator adjust

ment will result in improper operation, discomfort

to occupants of conditioned space, and inefficient

energy utilization; however, required setting may be

changed slightly to provide a greater degree of

comfort for a particular installation.

START-UP

Unit Preparation

WARNiNG/DANGER: Failure to observe ifee

foliowirig warnbigs could result m serious

personal injury;

1. Follow recognized safety practices and wear

protective goggles when checking or servicing

refrigerant system.

2. Do not operate compressor or provide any

electric power to unit unless compressor

terminal cover is in place and secured.

3. Do not remove compressor terminal cover until

all electrical sources have been disconnected.

4. Relieve all pressure from system before touching

or disturbing anything inside terminal box if a

refrigerant leak is suspected around compressor

terminals.

5. Do not use a torch to remove any component.

System contains oil and refrigerant under

pressure. To remove a component, wear protec

tive goggles and proceed as follows:

a. Shut off gas supply and then electrical

power to unit.

b. Relieve all pressure from system.

c. Cut component connecting tubing with

tubing cutter and remove component from

unit.

d. Carefully unsweat remaining tubing stubs

when necessary. Oil can ignite when exposed

to torch flame.

PRE-START-UP PROCEDURES ^ Proceed as

follows to inspect and prepare unit for initial

start-up:

1. Remove all access panels.

2. Read and follow instructions on all WARNING,

CAUTION, and INFORMATION labels

attached to or shipped with the unit, such as

blower rotation labels, etc.