More than 0.3 in. wg – Carrier 48GH User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

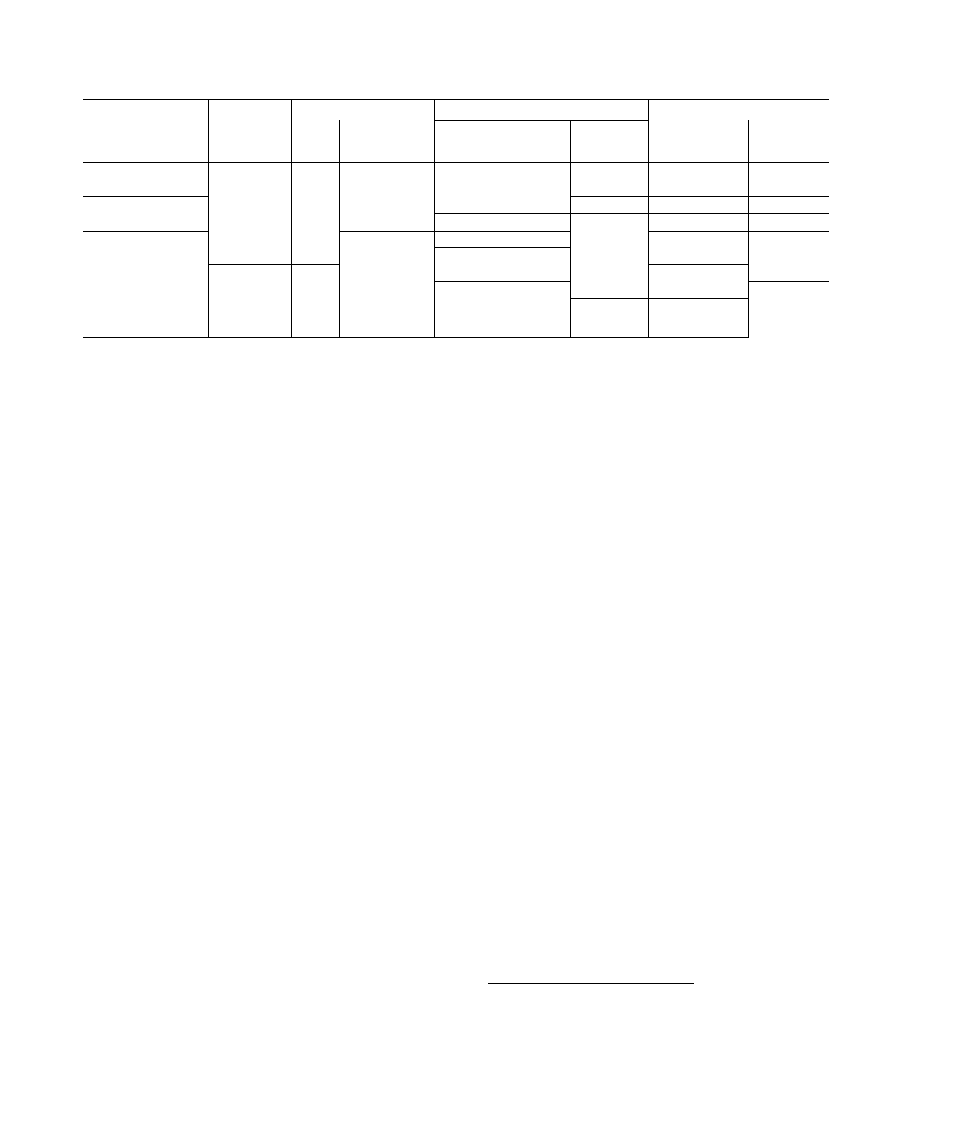

Table 3 — Rated Gas Inputs (Btuh) for Various

Burner Orifices at Indicated Manifold Pressures*

NUMBER

OF

ORIFICES

MANIFOLD

NATURAL GAS

LP (Propane) GAS

MODEL

48

P

Nat

KfcSSUHt

(in. wg)

LP (Propane)

Orifice

Part No.

Heating

Input

(Btuh)t

Orifice

Part No

Heating

Input

(Btuh)t

GL018,024,030

2

3 5

105

LH32DB-205t

(Min)

LH32DB-207 (Max)

40.000

50.000

LH32DB-201

LH32D

b

'-060”" '

40.000

50.000

GH024.030

3

3 5

105

LH32DB-205t (Min)

60,000

LH32DB-201

60,000

GL036,042

LH32DB-207 (Max)

75,000

LH32DB-060

75,000

GH042; GL048

4

3 5

105

LH32DB-200t (Min)

80,000

LH32DB-201

80,000

LH32DB-096 (Max)

100,000

LH32DB-060

100,000

GH036.048

5

3 5

105

LH32DB-200t (Min)

100,000

LH32DB-201

100,000

GL060

LH32DB-096 (Max)

125,000

LH32DB-060

125,000

GH060

6

3 5

10 5

LH32DB-200I

(Min)

LH32DB-096 (Max)

120,000

150,000

LH32DB-201

LH32DB-060

120,000

150,000

*Data in this table is based on altitudes from sea level up to either

7000 ft above sea level at the minimum rated input, or 2000 ft

above sea level at the maximum rated input For higher altitudes,

follow the recommendations of national and local codes

fGas inputs for natural gas are based on a heating value of

1050 Btu per cu ft with a specific gravity of 0 65 at the factory-set

manifold pressure of 3 5 in wg Gas inputs for LP (propane) gas

are based on a heating value of 2500 Btu per cu ft with a specific

gravity of 1 5 at a manifold pressure of 10 5 in wg

iThese natural gas burner orifices are the factory-supplied orifices.

All other natural gas orifices shown are optional field-supplied

orifices

#

The minimum and maximum rated gas inputs

shown in Table 3 are for altitudes from sea level up

to either 7000 ft above sea level at minimum input,

or 2000 ft above sea level at maximum input. These

inputs are based on natural gas with a heating value

of 1050 Btu per cubic foot at 0.65 specific gravity,

or LP (propane) gas with a heating value of 2500 Btu

per cubic foot at 1.5 specific gravity. For elevations

above either 7000 ft at minimum input or 2000 ft

at maximum input, reduce ratings 4% of maximum

input for each 1000 ft above sea level. When gas

supply being used has a different heating value or

specific gravity, refer to Carrier training and

application materials, national and local codes, or

contact your Carrier dealer to determine required

orifice size.

ADJUSTING GAS INPUT

CAUTION; WbsD adjusting ihe gas input, do

not change manifold pressure

more than

0.3 in. wg

above or below setting shown in

'Fable 3. if larger adjustments are required,

change burner orifices foUowditg recommenda

tions of national and local codes.

Gas input to unit is adjusted by changing mani

fold pressure. Use REG ADJ screw on gas valve to

change manifold pressure as follows:

To increase input: Turn screw clockwise.

To decrease input: Turn screw counterclockwise.

Gas input can be determined and adjusted by

using one of the following 2 recommended methods:

1. Measuring gas flow at meter.

2. Measuring manifold pressure.

Measuring Gas Flow at Meter

NOTE: All other gas appliances that use the same

meter must be turned off when the gas flow is

measured at the meter.

Proceed as follows to measure gas flow at meter

to determine gas input:

a. Determine number of seconds for gas meter test

dial to make one revolution.

b. Divide number of seconds in step a into 3600

(number of seconds in an hour).

c. Multiply result of step h by number of cu ft

shown for one revolution of test dial to obtain

cu ft of gas flow per hour.

d. Multiply result from .v/cp c by Btuh heating value

of gas to obtain total measured input in Btuh.

Compare this value with input shown in Table 3.

NOTE: Consult local gas supplier if heating value of

gas is not known.

Example: Assume that size of the test dial is 1 cu ft,

one revolution takes 30 seconds, and heating value

of gas is 1050 Btuh per cubic foot, then proceed

as follows:

a. 30 seconds to complete one revolution.

b. 30 divided into 3600 equals 120.

c. 120 times 1 equals 120 cu ft of gas flow per hour.

d. 120 times 1050 equals 126,000 Btuh input.

If desired gas input is 125,000 Btuh, only a minor

change in manifold pressure is required.

Measuring Manifold Pressure — When heating

value of gas is significantly more or less than design

value, or slight manifold pressure changes are

necessary for other reasons, manifold pressure

may be changed to adjust gas input. Use a water

manometer to measure manifold pressure. If a

spring manometer is used, make sure manometer

is calibrated.

10