Safety considerations, Introduction, General – Carrier 48GH User Manual

Page 2: Installation step 1 — rig and place unit, Step 1 — rig and place unit

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ge

16

17

20

22

lOX

a

)36;

O

SAFETY CONSIDERATIONS

Installation, start-up and servicing of this equip

ment can be hazardous due to system pressures,

electrical components and equipment location

(roofs, elevated structures, etc.).

Only trained, qualified installers and service

mechanics should install, start-up and service this

equipment.

Consult the Owner’s Manual for routine main

tenance. All other operations should be performed

by trained service personnel.

When working on the equipment, observe pre

cautions in the literature, tags, stickers and labels

attached to the equipment and any other safety

precautions that apply.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging and setting bulky

equipment.

WARNING; Do Hot discosaect electric power

to this appliance wiiliout

Htst

mrnirfg oft the gas

supply. Be sure power to ©quipmeot is shut off

before perforuiiug maintenance (»r service.

INTRODUCTION

Models 48GH/GL Packaged Gas/Electric Units

are fully self-contained, combination gas-heating/

electric-cooling units designed for outdoor installa

tion either on a rooftop or ground-level slab. See

Fig. 1.

These units are equipped with an energy-saving

automatic intermittent electric spark ignition system

that does not have a continuously-burning pilot.

Also included is the Time Guard II circuit for added

compressor protection. All units are manufactured

with natural gas controls.

Models 48GH/GL are AG A design-certified with

2 input ratings. See Table 1. All units are manu

factured for operation at the minimum rating. For

operation at the maximum ratings, optional burner

orifices must be field installed. See Table 3.

These units are factory charged with R-22 refrig

erant. To install: connect gas supply, air ducts, high-

and low-voltage wiring, condensate drain, and

install a field-supplied air filter in the return-air

ductwork.

All units can be connected into existing duct

systems that are properly sized and designed to

handle an airflow of 350 to 450 cfm per each 12,000

Btuh of rated cooling capacity. See Tables 1 and 4

for cooling and heating airflow requirements.

NOTE: When installing any accessory item, see

Installation Instructions packaged with the

accessory.

IMPORTANT —

READ BEFORE INSTALLING

L

This insiaUation must conform with all

applicable local and national codes.

2. Power .supply (volts, hertz and phase) must

correspond to that specified on unit rating

plate.

3- Elecíríeal supply provided by utility mast be

sufikient to handle load imposed by this unit.

4. Refer to the 4SGH / GL dimensionai drawing

for locations of gas inlet, elearical inlets,

condensate drain, duct connections, and

required clearances before setting unit in

place.

5. Locate the nnit where the vent cap will be a

minimum of 4 ft from openable windows or

doors.

6. This installation must conform with local

building codes and with the National Fuel

Gas code ANSÍ Z223.1-1980.

GENERAL

Models 48GH/GL Packaged Gas/Electric Units

have been designed and tested in accordance with

ANSI Z21.47-1978, ARI Standard 210-79 and ARI

Standard 270-75. The appliance design is certified

by the American Gas Association (AGA) for use

with natural or LP (propane) gases with appropriate

components and orifices.

INSTALLATION

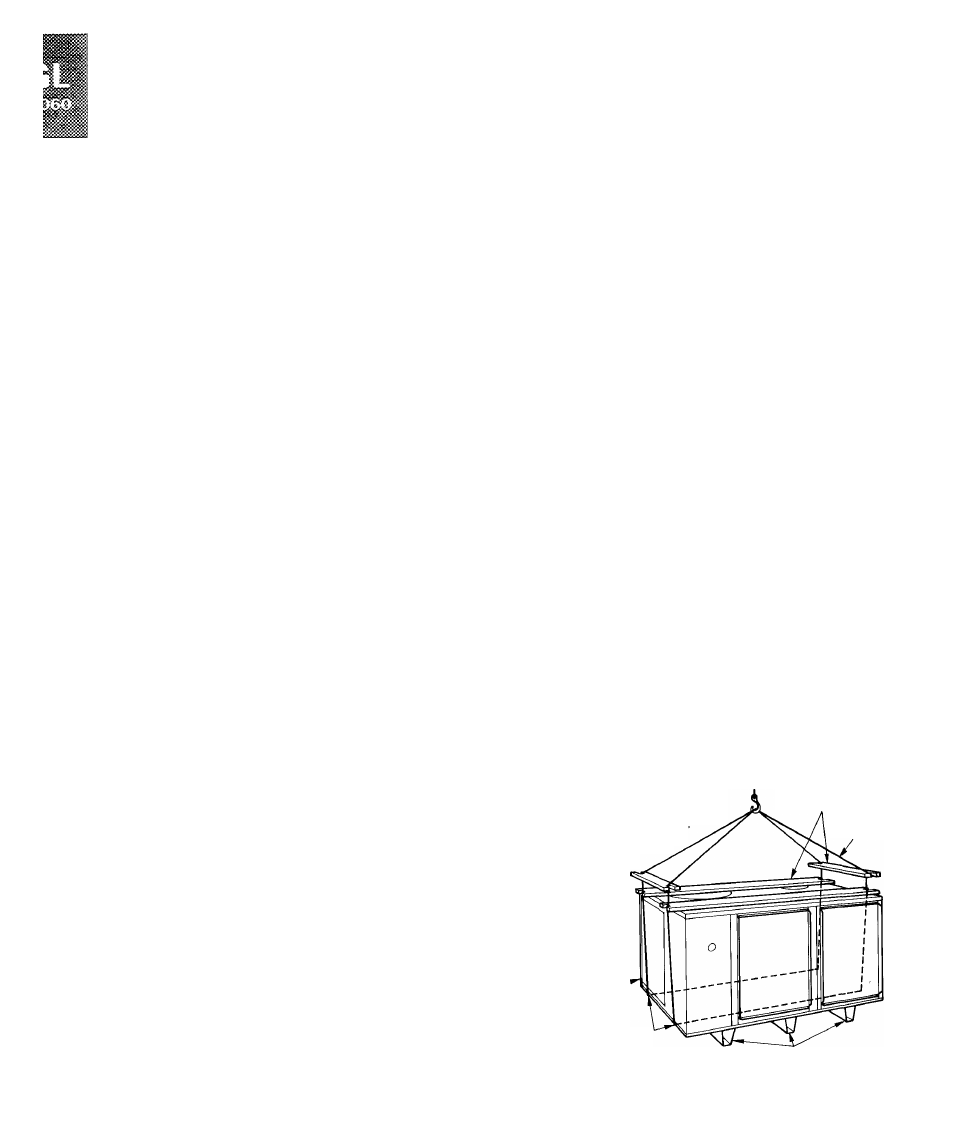

Step 1 — Rig and Place Unit

CAUTION: W'hen rigging unit to be lifted, use

spreader bars to protect top and sides. Models

4^GH/GL must he rigged for lifting as shown

in Fig, 2. Use extreme caution to prevent

damage when moving unit.

SPREADER BARS:

(2)2x4xUNIT LENGTH PLUS IO"WITH

if DEEP 90° NOTCHES EACH END

(2) 2x4xUNIT WIDTH WITH 1^’

DEEP 90° NOTCHES

EACH END

USE SPREADER BARS

TO PROTECT UNIT

CHAIN

PACKAGED UNIT-

LOCATE CHAINS THRU

HOLES IN BASE

CHANNELS

TWO OR THREE BASE

CHANNELS ATTACHED TO

BOTTOM OF UNIT

Fig. 2 — 48GH/GL Suggested Rigging

5SI