Carrier 48GH User Manual

Page 7

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

1. Make all electrical connections in accordance

with National Electrical Code and local elec

trical codes governing such wiring.

2. Use only copper conductor for connections

between field-supplied electrical disconnect

switch and the unit. Do not use aluminum or

copper-clad aluminum wire.

3. Ensure that high-voltage power to unit is within

operating voltage range indicated on unit rating

plate. On 3-phase units, ensure that phases are

balanced within 2%. Consult the local power

company for correction of improper voltage

and/or phase imbalance.

4. Insulate low-voltage wires for highest voltage

contained within conduit when low-voltage

control wires are run in same conduit as high-

voltage wires.

5. Do not damage internal components when

drilling thru any panel to mount electrical

hardware, conduit, etc.

6. Make sure that service conductors used between

the electrical service panel and field-supplied

electrical disconnect switch do not have a current

capacity less than the copper wire specified, and

do not create a total voltage drop in excess of 2%

of rated voltage of the unit.

NOTE: When using aluminum conductor from

electrical service to disconnect switch (where local

codes permit use of aluminum wire), make the

connections in accordance with National Electrical

Code. Prepare all aluminum wire immediately be

fore installation by “brush-scratching” the wire,

then coating the wire with a corrosion inhibitor

(such as Pentrox A). Be sure that entire connection

is completely covered to prevent an electrochemical

reaction that will cause the connection to fail very

quickly. Do not reduce effective size of wire by

cutting off strands to fit wire into a connector.

Always use properly sized connectors.

HIGH-VOLTAGE CONNECTIONS ^ Unit must

have a separate electrical service with a field-

supplied, waterproof, fused disconnect switch per

NEC mounted at, or within sight from, the unit.

Refer to unit rating plate for maximum fuse size and

minimum circuit amps (ampacity) for wire sizing.

Table 2 shows recommended wire sizes and lengths

based on rating plate data.

The field-supplied disconnect switch box may be

mounted on unit over the high-voltage inlet hole

in control corner panel. See Fig. 1.

WARNING: Label part no, A-74I9ÍB, whickis

shipped loose in bag of parts,

must be affixed

to

the disconnect switch, box. This iabei states;

“DO NOT DISCONNECT THE ELEC

TRICAL POW'ER TO THIS APPLIANCE

WITHOUT FIRST TURNING OFF THE

GAS SUPPLY ”

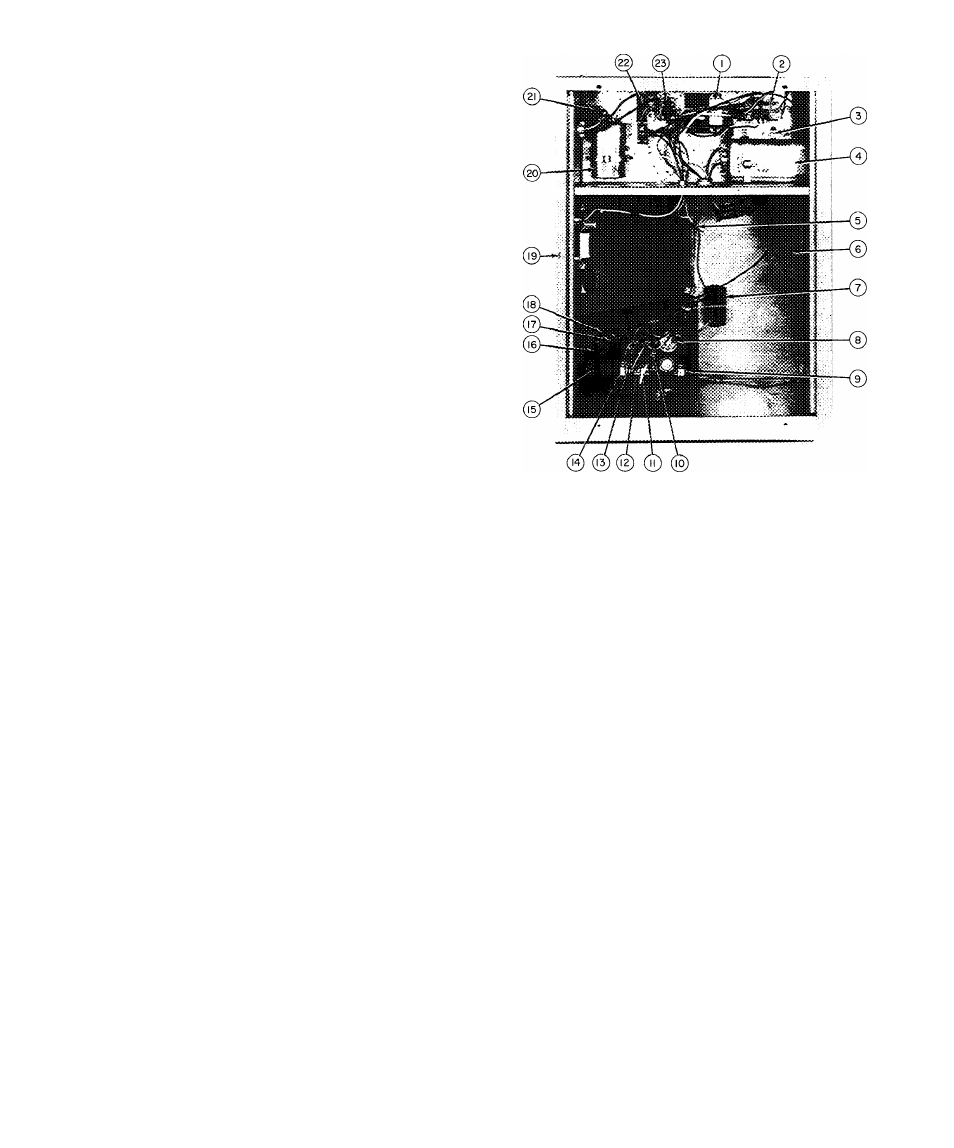

1 — Control Transformer

2 — Compressor Contactor

3 — Ground Lug

4 — Dual Run Capacitor

(for compressor and

condenser fan motor)

5 — Low-Voltage Pigtail

Leads

6 — Compressor/Control

Compartment Divider

Panel

7 — Igniter Module

8 — Manual On/Off Knob

9 — Gas Valve Inlet

10 — Pipe Plug —

LP (Propane) unit

pressure switch

mounts here

11 — Pilot Tube

12 - Model 646A-X

Gas Valve

13 — Pressure Tap Pipe Plug

14 — Gas Valve Outlet

15 — Gas Manifold

16 — Gas Burner

17 — Burner Air Shutter

18 — Secondary-Air Shield

19 — Blower Housing

20 — Evaporator Motor

Run Capacitor

21 — Blower/Control

Compartment

Divider

Panel

22 — Heating Relay

23 — Cooling Relay

Fig. 6 — Model 48GL036 — Side View

(Partial) with Access Doors Removed

Proceed as follows to complete the high-voltage

connections to unit:

1. Connect ground lead to chassis ground connec

tion when using a separate ground wire.

2. Run high-voltage leads with field-supplied

conduit into unit control box and connect to

contactor. See unit wiring label, and Fig. 6

and 7.

NOTE: On 3-phase units, connect third high-voltage

lead to brown high-voltage pigtail lead. See unit

wiring label and Fig. 7.

SPECIAL PROCEDURES FOR 208-V

OPERATION

WARNING; Make stire that power supply to

«iut k switched OFF before ruakipg any wiring

changes.