Caution; doling opersaion, recota, Wt , raimg plate, Teas – Carrier 48GH User Manual

Page 13: Bivtk, Cotmìctìo-m

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

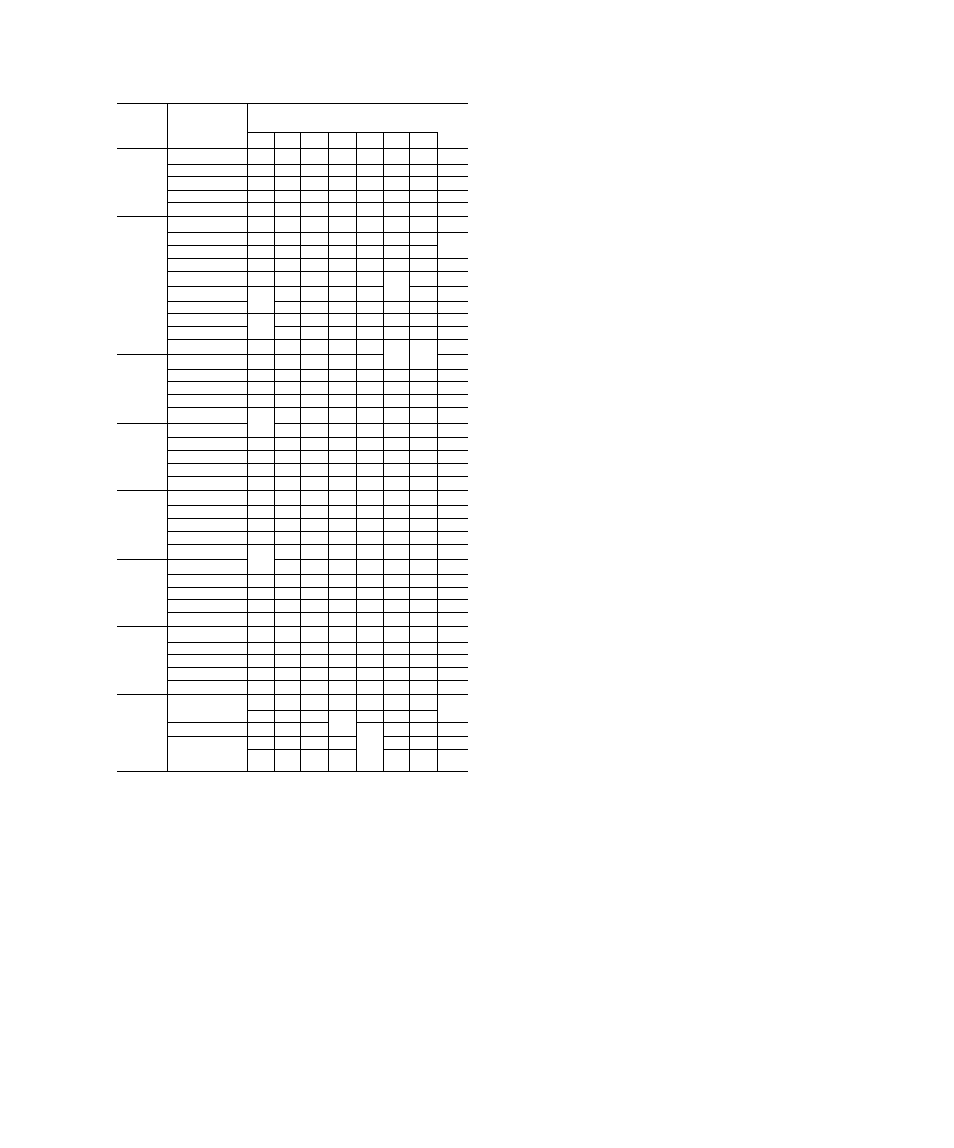

Table 5 — Refrigerant (R-22) Charge

Check Charts*

MODEL

48

EVAPORATOR

AIR INLET

CONDENSER AIR INLET TEMP (F)

WET BULB (F)

65

70

75

80

85

90

95

100

55

138 156 174 192 211 229 247 265

60

143 161 178 196 213 231 249 266

GL018

65

148 165 182 199 216 233 251 268

70

153 169 186 202 219 236 252 269

75

158 174 190 206 222 238 254 270

55

157 170 183 197 210 223 238 253

60

158 172 185 198 212 225 240 255

GL024

65

160 173 187 200 214 228 243 259

70

161 175 189 202 217 232 247 262

75

163 177 191 205 220 235 251 267

55

148 163 178 193 208 224 239 254

60

150 165 181 195 211 226 241 256

GH024

65

151 167 182 197 213 228 243 258

70

153 169 184 199 215 230 245 261

75

155 171 186 202 217 232 247 263

55

163 178 193 208 220 235 247 262

GL030,

GH030

60

165 180 195 210 223 238 251 266

65

167 182 197 212 226 241 255 270

70

169 184 199 214 229 244 259 274

75

171 186 201 216 232 247 263 276

55

172 186 200 214 229 244 260 274

60

175 190 204 218 233 248 264 278

GL036

65

178 193 208 222 238 252 268 282

70

182 197 212 226 241 256 271 286

75

185 200 215 230 245 260 275 290

55

168 182 196 209 223 238 253 268

60

171 185 199 213 228 243 259 276

GH036

65

173 188 203 217 233 248 266 283

70

175 191 206 221 237 253 271 288

75

176 193 209 225 242 258 275 292

55

177 192 208 224 239 253 269 285

GL042,

GH042

60

180 195 211 227 243 258 274 290

65

183 198 214 230 247 263 279 295

70

186 201 217 233 251 268 284 300

75

189 204 220 236 255 273 289 305

55

171 182 193 204 216 228 242 257

GL048.

GH048

60

176 188 200 211 224 237 251 265

65

181 193 206 218 232 245 258 274

70

185 197 210 223 238 252 267 282

75

188 201 215 228 243 258 274 291

55

173 190 204 219 236 251 266 280

GL060.

GH060

60

175 192 207 223 240 256 272 287

65

177 194 210 227 244 261 278 294

70

179 196 213 231 248 266 284 301

75

181 198 216 235 252 271 290 308

*Table shows recommended discharge pressures at compressor (psig)

5. Evaluate system performance and refrigerant

charge by comparing recorded readings with

operating pressure/temperature tag.

6. Make slight adjustment to refrigerant charge

when necessary.

NOTE: If problem causing inaccurate readings is

a refrigerant leak, see Unit Preparation — RE

FRIGERANT LEAKS.

INDOOR AIRFLOW AND AIRFLOW AD

JUSTMENTS — Models 48GH/GL have direct-

drive blower motors. All motors are factory

connected to deliver proper heating and cooling

airflows at normal external static pressures (except

for some 208-v applications).

CAUTiON; doling opersaion, recota-

fscfsticd airflow is 35& to 450 cfm per 12^^

Bivtk

of xaied ooogng capacity. For

operatioo, airflow iami ptodwce a teaaijoraaésffo

rise that faOs withia ras^e staw«^

ojì

. Wt ,

raimg plate.

Table 4 shows heating airflow at various tempera

ture rises. Table 6 shows both heating and cooling

airflows at various external static pressures. Refer

to these tables to determine airflow for system being

installed. See Tables 1 and 6 for cooling airflow.

NOTE: Be sure that all supply- and return-air

grilles are open, free from obstructions and

adjusted properly.

WARNING; Dii

OHil perore c&aoging

my

teas

cotmìctìo-m

ot

......................................................

■ 'iliiill...........■ "

NOTE: When operating the 208/230-volt, 3-phase

version of size 48GH048 at 208 volts, change lead

connections of the blower motor as indicated on

unit wiring label to insure a proper airflow.

The heating and/or cooling airflow of 208/230-v

motors can be changed by changing lead connec

tions of blower motor. Motor leads are color-coded

as follows:

black - high speed

blue - medium speed

red - low speed

NOTE: Some blower motors do not have lead for

medium speed. Factory connections and available

optional connections are shown in Table 6.

For all units, motor lead connected to time delay

relay (heating) determines heating speed and

resulting airflow; and motor lead connected to

indoor fan relay (cooling) determines cooling speed

and resulting airflow. See unit wiring label.

To change heating and/or cooling speed, connect

appropriate color-coded lead to appropriate relay.

Be sure to properly insulate any unused motor lead.

See Typical Wiring SPECIAL PROCEDURES

FOR 208-V OPERATION for proper procedures to

insulate an unused electrical lead.

When installing a 208- or 230-v unit that is

factory connected for heating and cooling speeds

that are not the same, and same speed for both

heating and cooling is required for a particular

application, connect appropriate color-coded lead

to terminal 2 of indoor fan relay (cooling) and

connect a field-supplied jumper between time delay

relay (heating) and terminal 2 of indoor fan

relay (cooling). Be sure to properly insulate unused

motor lead(s).

13