Testing policy, Introduction and description – Winco ULPSS90/D WITH DSE 7310 CONTROL (2014) User Manual

Page 4

4

48-00

60706-51

TESTING POLICY:

Before any generator is shipped from the factory, it is fully

checked for performance. The generator is loaded to its full

capacity, and the voltage, current, and frequency are carefully

checked.

Rated output of generators is based on engineering tests of

typical units, and is subject to, and limited by, the temperature,

altitude, fuel, and other conditions specified by the manufacturer

of the applicable engines.

INTRODUCTION AND

DESCRIPTION

With the addition of an Automatic Transfer Switch this packaged

standby system includes all items necessary for a completely

automatic standby power system.

DESCRIPTION

This package power system is designed to automatically provide

standby power to unattended loads during electrical outages.

Upon an interruption of normal electrical service this package

power system’s electrical control circuits will automatically start

the engine. The generator will produce electrical power and the

Automatic Transfer Switch (A.T.S.) will automatically transfer the

electrical loads to the engine-generator set. Upon restoration

of normal electrical service the A.T.S. will sense return of the

normal commercial power and retransfer the load back to normal

commercial power source. The engine control circuits shut off the

run signal to the engine generator set.

These package power systems consist of two major

components:

1) AUTOMATIC TRANSFER SWITCH (UL LISTED)

The Automatic Transfer Switches (A.T.S.) is a wall mount switch

designed for inside installation. An electronic exerciser circuit

is installed in the A.T.S. as standard equipment. The A.T.S. also

contains the power failure sensing circuitry necessary to send

a start/stop signal to the engine generator set. The following

is a list of recommended A.T.S. sizes for each model. Outside

switches as well as additional sizes are available, consult your

sales rep for additional information.

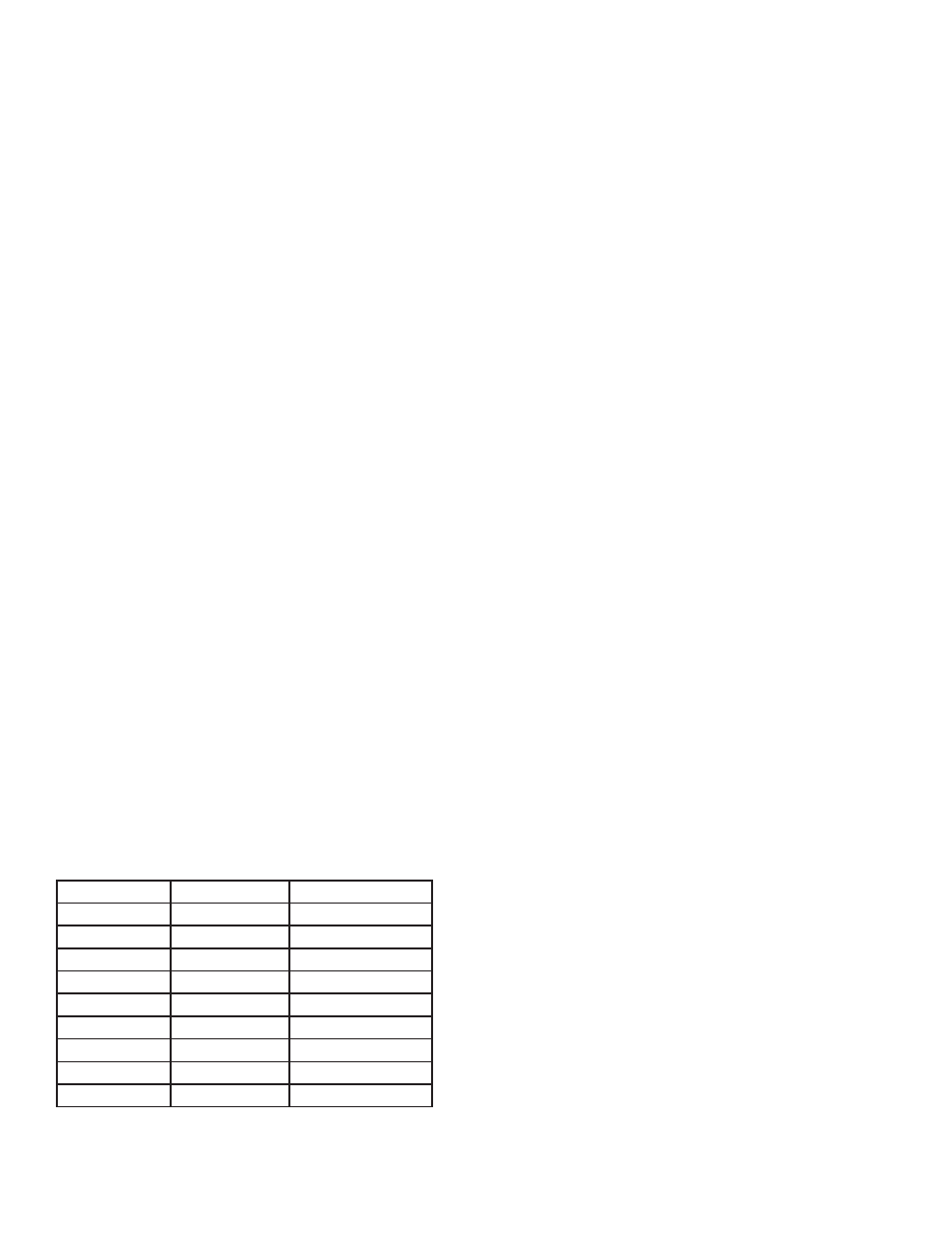

RECOMMENDED

MODEL

VOLTAGE

ATS AMPERAGE

PSS60-3

10/40

400

PSS60-4

10/08

400

PSS60-17

10/40

00

PSS60-18

77/480

100

PSS90-3

10/40

400

PSS90-4

10/08

400

PSS90-17

10/40

400

PSS90-18

77/480

00

Additional optional A.T.S. sizes are available to meet specific

needs. Contact your local WINCO dealer or the WINCO Sales

Department for a quote.

2) ENGINE/GENERATOR

PSS60- The engine generator set consists of a GM 5.7L, V-8

industrial, liquid-cooled engine equipped to run on L.P./N.G. fuel.

The engine operates at 1800 rpm and frequency regulation is

maintained by the electronic governor within .5 cycles variation,

from no load to rated load. The 60,000 watt (60kW) generator is

a single bearing, direct drive, rotating field design. The generator

is connected to the engine flywheel via flexible drive disks.

The engine generator is mounted in a weather proof enclosure

for outside installation. Connection boxes are provided to all

customer connections (both AC output and DC control). A

customer supplied 12 Volt, 650 CCA (BCI group 24) battery

is required to complete the installation. Engine operation is

controlled by a Deep Sea (DSE) engine control mounted in the

engine generator enclosure.

PSS90 - The engine generator set consists of a GM 5.7L,

Turbocharged/Aftercooled V-8 industrial, liquid-cooled engine

equipped to run on L.P./N.G. fuel. The engine operates at

1800 rpm and frequency regulation is maintained by the engine

governor within .5 cycles variation, no load to rated load. The

90,000 watt (90kW) generator is a single bearing, direct drive,

rotating field design. The generator is connected to the engine

flywheel via flexible drive disks. The engine generator is

mounted in a weather proof enclosure for outside installation.

Connection boxes are provided to all customer connections

(both AC output and DC control). A

customer supplied 1 Volt,

650 CCA (BCI group 24) battery is required to complete the

installation. Engine operation is controlled by a Deep Sea (DSE)

engine control mounted in the engine generator enclosure.

** NOTICE **

These units will automatically transfer if a power outage occurs

while running in an exercise mode.

ENGINE CONTROL MODULE (DSE 7310 Series)

The DSE 7310 Series control modules provide integrated engine

and generator set control, protection and metering in a single

package. Microprocessor based technology allows for exact

measurement, set point adjustment, and timing functions. Front

panel controls and indicators enable quick and simple operation.

Fully configurable via PC software, allows units to be easily

customized for each application. Includes selected front panel

programming for on site changes. A wide temperature-range

liquid crystal display (132 x 64) with backlighting can be viewed

under a wide range of ambient light and temperature conditions.

FEATURES

DSE 7310 Control Modules have the following features:

Local and Remote Generator Control

Engine and Generator Protection

CAN Bus Compatible

Programmable Logic

Five-key Menu Navigation

Engine Exercise Mode

Automatic Transfer Switch Control (Mains Failure)

User Selectable RS232 & RS485 (Remote Operation)