Winco ULPSS90/D WITH DSE 7310 CONTROL (2014) User Manual

Page 18

18

48-00

60706-51

Operation & Maintenance Manual

Certified Stationary Product

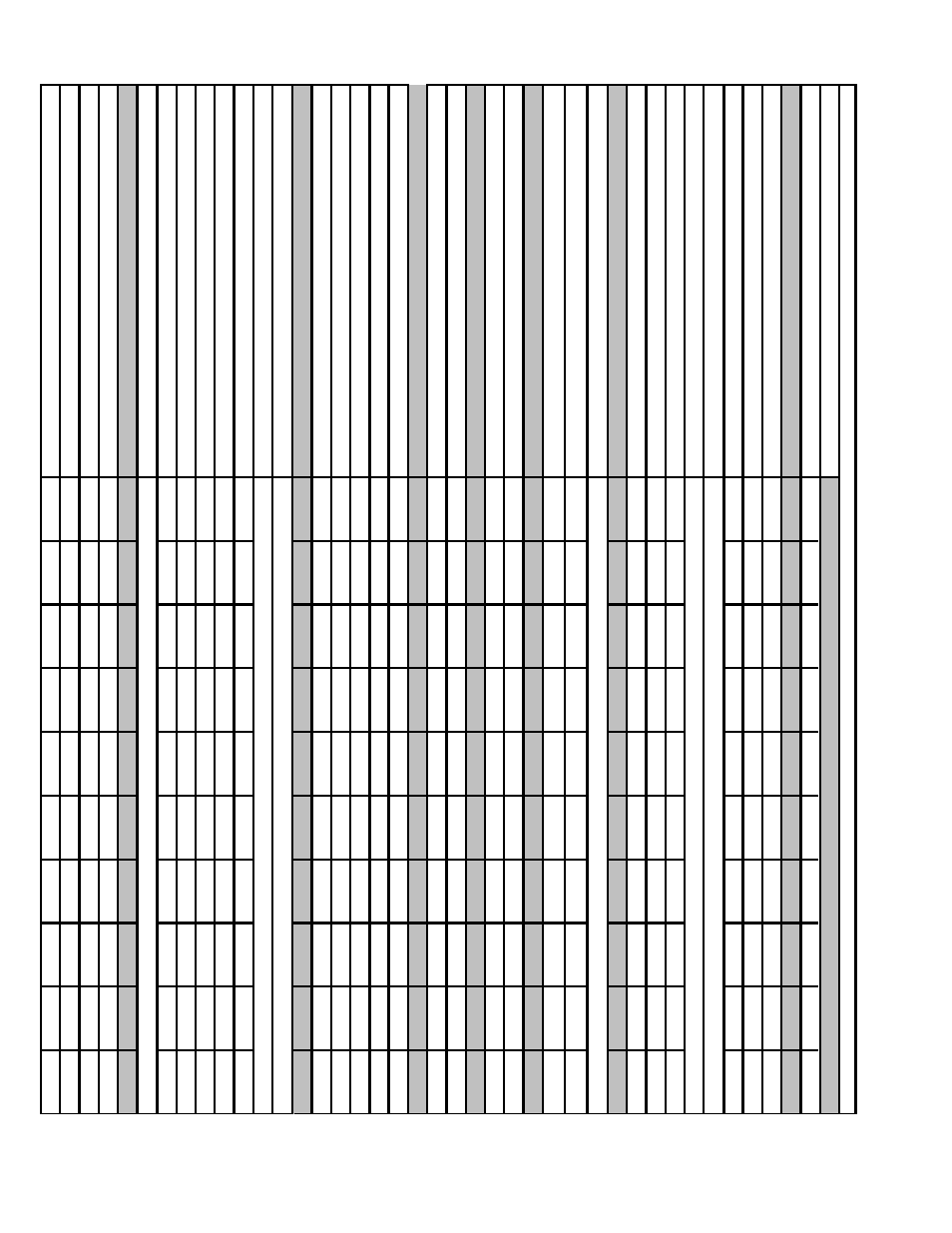

15

Daily

1000

1500

000

500

3000

3500

4000

4500

5000

General Maintenance Section

Visual check for fluid leaks

X

Check engine oil level

X

Check coolant level

X

Change engine oil and filter

Check LPG system for leaks

In

sp

ec

ta

cc

es

so

ry

dri

ve

be

lts

fo

rc

ra

ck

s,

bre

ak

s,

sp

lits

or

gla

zin

g

X

X

X

X

X

Inspect electrical system wiring for cuts, abrasions or corrosion

X

X

Inspect all vacuum lines and fittings for cracks, breaks or hardening

X

X

Engine Coolant Section

Clean debris from radiator core

Change coolant

X

X

X

X

X

Inspect coolant hoses for cracks, swelling or deterioration

X

X

X

X

X

Base Engine – Prime Engines

Compression Test

X

X

X

Replace/Rebuild Cylinder Heads

X

X

Base Engine – Turbo Charged Emergency Engines

Replace/Rebuild Cylinder Heads

X

X

Replace Turbo Charger

Engine Ignition System

X

X

X

X

X

Replace spark plugs

X

X

Clean secondary ignition coil tower

X

X

X

X

X

Check spark plug wires for cuts abrasions or hardening

X

Replace distributor cap and rotor

X

X

Replace spark plug wires

X

X

Fuel System Maintenance

Inspect air cleaner

Replace filter element

Replace fuel filter

X

X

X

X

X

Inspect Shut-off Valve for leaks and closing

X

X

Leak check fuel lines

X

X

Check air induction for leaks

X

X

X

X

X

Check manifold for vacuum leaks

X

X

X

X

X

Drain Vaporizer oil build up

Engine Exhaust System

Inspect exhaust manifold for leaks

X

X

Inspect exhaust piping for leaks

X

X

Check HEGO sensor(s) connector and wires for burns, cuts or dam

age

X

X

Inspect catalyst for mechanical damage

X

X

Annually, or as required in dusty environments

Every 2500 hrs

Every 200 hours, or every 100 hours in dusty environment

Prior to any service or maintenance activity

Every 100 hours or 60 days of operation

CERTIFIED STATIONARY ENGINE MAINTENANCE REQUIREMENTS

Perform the following maintenance on the engine at the hours indicated and at equivalent hour intervals thereafter.

Interval Hours

Every 150 hours or 120 days of operation