A.c. electrical connections – Winco ULPSS90/D WITH DSE 7310 CONTROL (2014) User Manual

Page 10

10

48-00

60706-51

** NOTICE **

The trickle charger is not intended to recharge a battery which

has become completely discharged. It is designed to produce

just enough current to maintain a fully charged battery.

The battery tender receptacle is to be powered by a GFCI circuit

and installed in accordance with the United States National

Electric Code. These AC wires can be run in the same conduit

as the other AC leads from the generator. It is suggested that

this circuit be fused for 15 amps, then both the battery charger

and the block heater can be connected to the same circuit. A

10 volt duplex receptacle is mounted on the generator along

side circuit breaker panel, the battery tender is shipped already

plugged into the receptacle.

The engine blockheater installed on this unit should also be

plugged in this receptacle. The block heater is thermostatically

controlled and when plugged in will maintain the engine coolant

temperature between 100 and 10 degrees F.

MOUNTING THE AUTOMATIC

TRANSFER SWITCH (A.T.S.)

****************

***** WARNING *****

****************

FIRE HAZARD - All wiring must be done by a licensed

electrician, and must conform to the national electrical code and

comply with all state and local codes and regulations. Check

with the local authorities before proceeding!

INSTALLATION NOTES

Because of the many different types of service, feeder, and

distribution equipment, no specific wiring instructions can be

provided. It is recommended that only copper wire be used.

In all cases it is essential that while the load is connected to

the generator, there can be absolutely no feedback from the

generator to the power line or the power line to the generator.

When properly installed, the normal A.T.S. Control and safety

systems will eliminate all paths for feedback.

To wire the automatic transfer switch into the existing wiring, first

determine which circuits will be on the emergency load circuit.

If the entire load is to be transferred, the transfer switch can

be wired in directly after the watt-hour meter and the service

entrance, providing the service entrance ampere rating is within

the transfer switch’s rated capability.

If only specific circuits are to be powered under emergency

power failure conditions, an additional distribution panel

designated “emergency distribution panel” must be installed.

All selected emergency circuits are removed from main

distribution panels and installed in the emergency distribution

panel. The A.T.S. is then installed between the main panel and

the emergency distribution panel. Suggested circuits: freezer,

refrigerator, furnace, emergency lights, sump pump, emergency

outlet circuits, etc. Total running load must not exceed generator

rating.

A.C. ELECTRICAL

CONNECTIONS

NOTICE - CLASS 1 WIRING METHODS ARE TO BE USED

FOR ALL FIELD WIRING CONNECTIONS TO TERMINALS

OF A CLASS 2 CIRCUIT

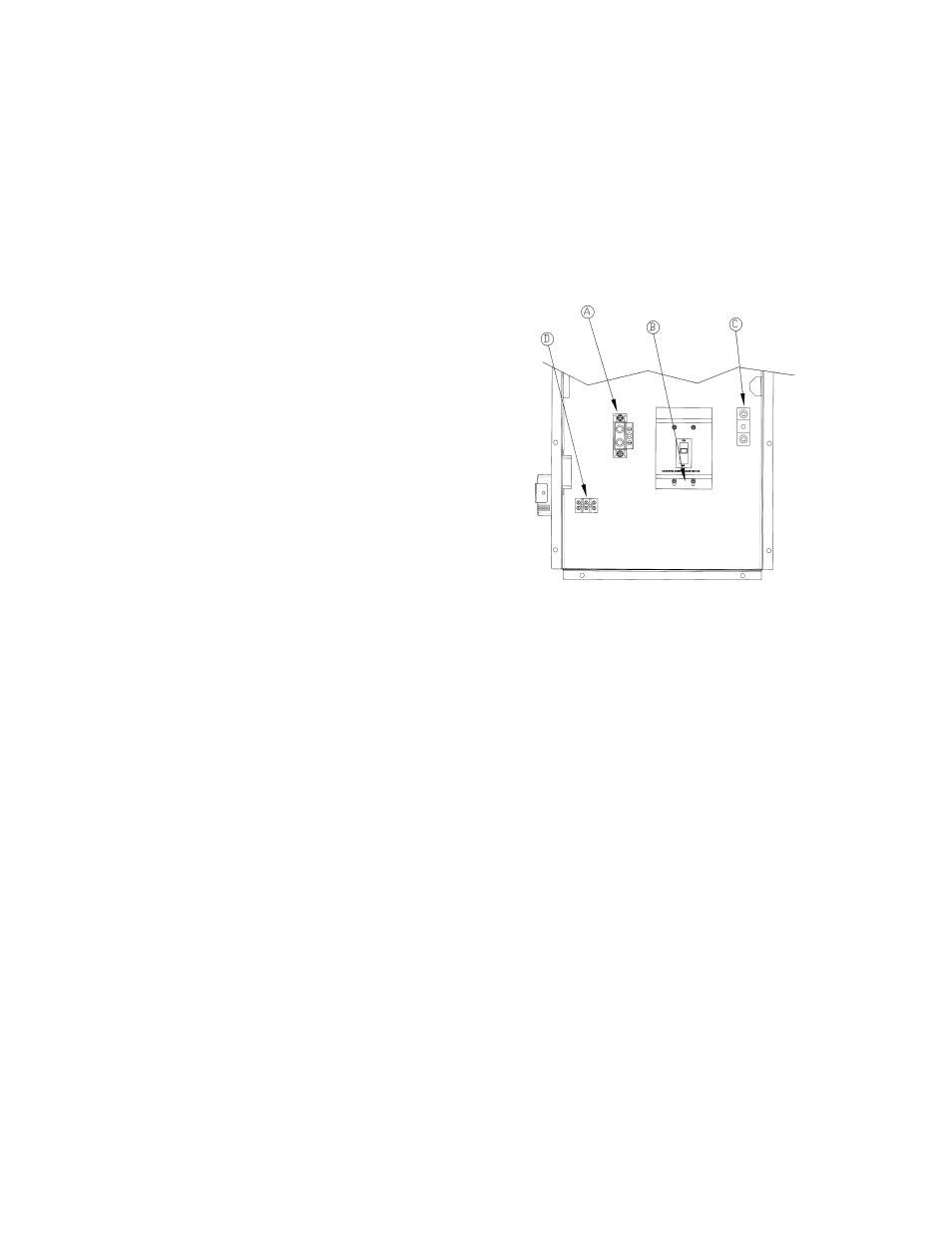

INSTALLERS NOTE: To access the AC and DC

interconnections on this unit, open the single door

on the right hand side of the units. Then remove the

safety panel covering the mainline circuit breaker. All

connection are behind this panel.

A- Neutral Lugs, These neutral lugs are isolated from ground

and provided for you to connect your neutral wire from the

transfer switch to. The lugs on the 90 kW will handle wire sizes

#1 AWG to 600 MCM and should be torqued to 300 in. lbs. The

lugs on the 60 kW will accommodate #4 AWG to 300 MCM and

should be torqued to 50 in. lbs.

B - Generator Circuit Breaker, This circuit breaker provides

overload protection for the generator. Your power feeds from

the transfer switch will connect to the bottom lugs on the circuit

breaker. The generator power feeds have already been wired

into the upper lugs.

The table below gives you the circuit breaker size, lug wire sizes

and torque specification. (see the actual breaker for additional

information and restrictions)

kW Voltage PH Amp

Wire Capability

Lug Torque

90 10/40 1 350

#1 AWG - 600 MCM 375 in lbs

90 10/08 3 300

#1 AWG - 600 MCM 375 in lbs

90 10/40 3 50

#1 AWG - 600 MCM 375 in lbs

90 77/480 3 150

#4 AWG - 300 MCM 50 in lbs

60 10/40 1 50

#1 AWG - 600 MCM 375 in lbs

60 10/08 3 00

#4 AWG - 300 MCM 50 in lbs

60 10/40 3 175

#4 AWG - 300 MCM 50 in lbs

60 77/480 3

90

#14 - #3/0 AWG

10 in lbs