Voltage regulator, Fitting and operating – Winco ULPSS90/D WITH DSE 7310 CONTROL (2014) User Manual

Page 19

19

48-00

60706-51

The automatic voltage regulator used standard on all models of the PSS60 and PSS90 is the AS440. The regulator is

preset at the factory and should never need adjustment. If you should ever need to adjust the regulator (i.e. you recon-

nect the generator for a different voltage) the only adjustment that should need to be made is the voltage pot. Below is a

description of the AS440, not all function are use on these models. Special order units may use different regulators.

VOLTAGE REGULATOR

ENGINE MAINTENANCE NOTES:

Engine oil: Use only engine oils displaying the API Certification

Mark “ FOR GASOLINE ENGINES” on the container. Gasoline

engines that are converted for LPG or NG fuels MUST use oils

labeled “FOR GASOLINE ENGINES”. Do not use oils that are

specifically formulated for Diesel Engines only. CC or CD clas-

sification oils, even when labeled Heavy Duty or for Natural Gas

Engines,

ARE NOT ACCEPTABLE.

Multi-viscosity oils are recommended. SAE 10W-30 is recom-

mended for your engine from 0 degrees F (-18 degrees C)

or above. If ambient temperatures are consistently below 0

degrees F. SAE 5W-30 oil can be used Synthetic oils are not

recommended for Industrial or Stationary engine.

Air Filter: Both the PSS60 and the PSS90 use the same air

filter, the IMPCO F1-15.

Spark Plugs: Both units use R4LTS or R44LTS

Oil Filter: Both units use PF-35 or PF-454

Coolant System: Check the coolant daily or after each use, and

only when the engine is cool. Maintain the coolant level 3/4 to 1

1/2 inches below the filler neck seat when the coolant is cold.

****************

***** WARNING *****

****************

EQUIPMENT DAMAGE - Never remove the radiator cap when

the engine is hot and never add coolant to any engine that

has become overheated. Either can cause personal injury

and damage to the engine.

The cooling system must be filled with a 50/50 mixture of

antifreeze and water The use of DexCool “Long Life” (typical

orange in color) type coolant is required.

SEE THE ENGINE OPERATORS MANUAL FOR ADDITIONAL

SERVICE INFORMATION

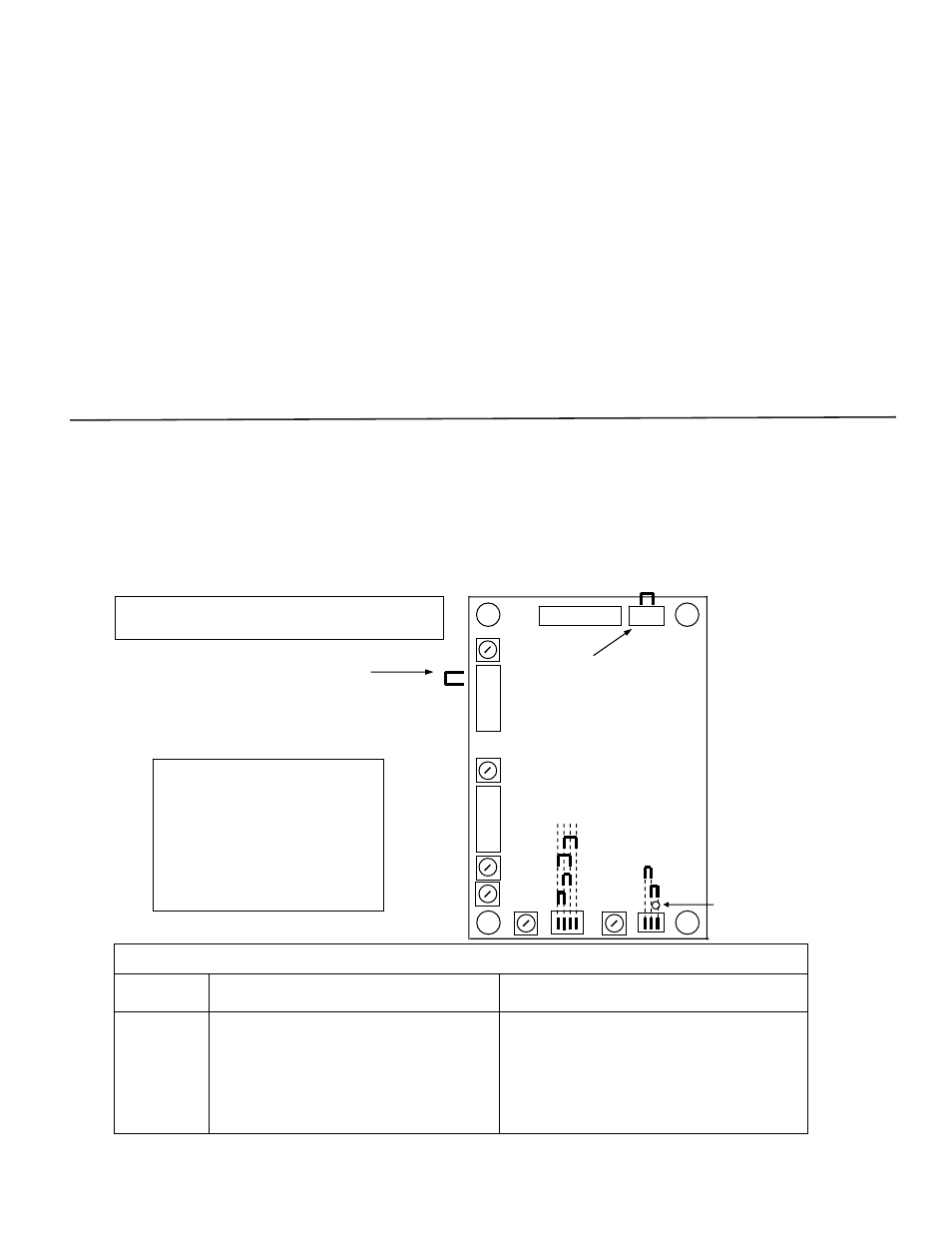

FITTING AND OPERATING

©006

3

TD_AS440 AVR_03.09_04_GB

SUMMARY OF AVR CONTROLS

CONTROL

FUNCTION

DIRECTION

VOLTS

TO ADJUST GENERATOR OUTPUT VOLTAGE

CLOCKWISE INCREASES OUTPUT VOLTAGE

STABILITY

TO PREVENT VOLTAGE HUNTING

CLOCKWISE INCREASE THE DAMPING EFFECT

STAB SWITCH TO OPTIMISE TRANSIENT PERFORMANCE

SEE TABLE ABOVE

UFRO

TO SET THE UFRO KNEE POINT

CLOCKWISE REDUCES THE KNEE POINT FREQUENCY

DROOP

TO SET THE GENERATOR DROOP TO 5% AT 0PF

CLOCKWISE INCREASES THE DROOP

VTRIM

TO OPTIMISE ANALOGUE INPUT SENSITIVITY

CLOCKWISE INCREASES THE GAIN OR SENSITIVITY

EXC TRIP

TO SET OVER EXCITATION TRIP CUT OFF LEVEL

CLOCKWISE INCREASES THE CUT OFF LEVEL

ADJUSTMENT OF AVR CONTROLS

VOLTAGE ADJUSTMENT

The generator output voltage is set at the factory, but

can be altered by careful adjustment of the VOLTS

control on the AVR board, or by the external hand

trimmer if fitted. If major adjustment is necessary or

you lose stability, follow the ‘

VOLTAGE SETUP

PROCEDURE

’.

Terminals 1 and on the AVR will be fitted with a shorting

link if no hand trimmer is required. Terminals La and Lb are

linked only for special low voltage applications.

WARNING! Do not increase the voltage above the rated

generator voltage. If in doubt, refer to the rating plate

mounted on the generator case.

WARNING! Do not ground any of the hand trimmer

terminals as these could be above earth potential. Failure

to observe this could cause equipment damage.

WARNING!

If a replacement AVR has been fitted or re-setting of the

VOLTS adjustment is required, turn the VOLTS control

fully anti-clockwise before running generator.

VOLTAGE SETUP PROCEDURE

For major adjustments and replacing the AVR.

Read and understand this procedure before

attempting to follow it.

1. Before running generator, turn the VOLTS control

fully anti-clockwise.

. Turn remote volts trimmer (if fitted) to midway

position.

3. Turn STABILITY control to midway position.

4. Connect a suitable voltmeter (0-300V ac) across

line to neutral of the generator.

5. Start generator set, and run on no load at nominal

frequency e.g. 50-53Hz or 60-63Hz.

6. If the red Light Emitting Diode (LED) is illuminated,

refer to the Under Frequency Roll Off (UFRO)

adjustment.

7. Carefully turn VOLTS control clockwise until rated

voltage is reached.

8. If instability is present at rated voltage, refer to

stability adjustment, then re-adjust voltage if

necessary.

9. Voltage adjustment is now completed.

REFER TO GENERATOR WIRING DIAGRAM

FOR CONNECTION DETAILS

F F1 7 8

8 Z

S1

S

A1

A

AS440

Trim

Droop

Volts

Stability

Selection

UFRO

Frequency

Selection

Indicator LED

Stab

60Hz

50Hz

1

3

Lb

La

ABCD

Stability Selection Table

No.

Power range Response

B-D

< 100kW

Slow

A-C < 100kW

Fast

B-C

100-550kW

Fast

A-B

> 550kW

Fast

Hand trimmer terminals. Remove

link before fitting hand trimmer.

Link must be fitted when hand

trimmer is not required.

Exc

Trip

8 and Z – linked for

normal operation