Repair kits and replacement parts, Specifications, Troubleshooting – Wilkerson ER2 User Manual

Page 6

Repair Kits and Replacement Parts

Control Board LCD 30/60 psig (2.0/4.0 bar) ..... ERP-95-786

Control Board LCD 90/125 psig (6.0/8.6 bar) ... ERP-95-788

Control Board, STD, 30/60 psig (2.0/4.0 bar) ... ERP-95-798

Control Board, STD, 90/125 psig (6.0/8.6 bar) . ERP-95-799

LCD Board and Ribbon ..................................... ERP-95-787

Intake Valve ....................................................... ERP-95-790

Exhaust Valve .................................................... ERP-95-791

Diaphragm Kit, ER1 ........................................... ERP-95-792

Diaphragm Kit, ER2 ........................................... ERP-95-793

Bottom Valve and Valve Spring ........................ ERP-95-794

Specifications

Min

Max

Nom

Units

Supply Voltage

12

28

—

VDC

Supply Current

—

250

80

mA

Control Signal

Voltage

0

10

—

VDC

Impedance

—

200

KOHM

Current

4

20

—

mA

Impedance

—

600

OHM

Internal

—

—

—

—

Monitor Output

0

10

—

VDC

Overall Accuracy

—

—

1.5%

SCALE

Supply Pressure

20

150

—

psig

(1.4)

(10.3)

—

(bar)

Output Pressure

0

30/60/90/125

psig

(0.0)

(2/4/6/8.6)

(bar)

Temperature

40

125

—

°F

(4.4)

(51.6)

—

(°C)

Flow Rate [150 psig (10 bar) inlet and 90 psig (6 bar)

outlet with a 5 psid (0.3 bar)]

ER1 ................................................................ 200 SCFM (94.3 dm

3

/s)

ER2 ................................................................ 200 SCFM (94.3 dm

3

/s)

Note: For optimum operation, inlet pressure should be a minimum

of 15 psig (1.0 bar) above the controlled pressure.

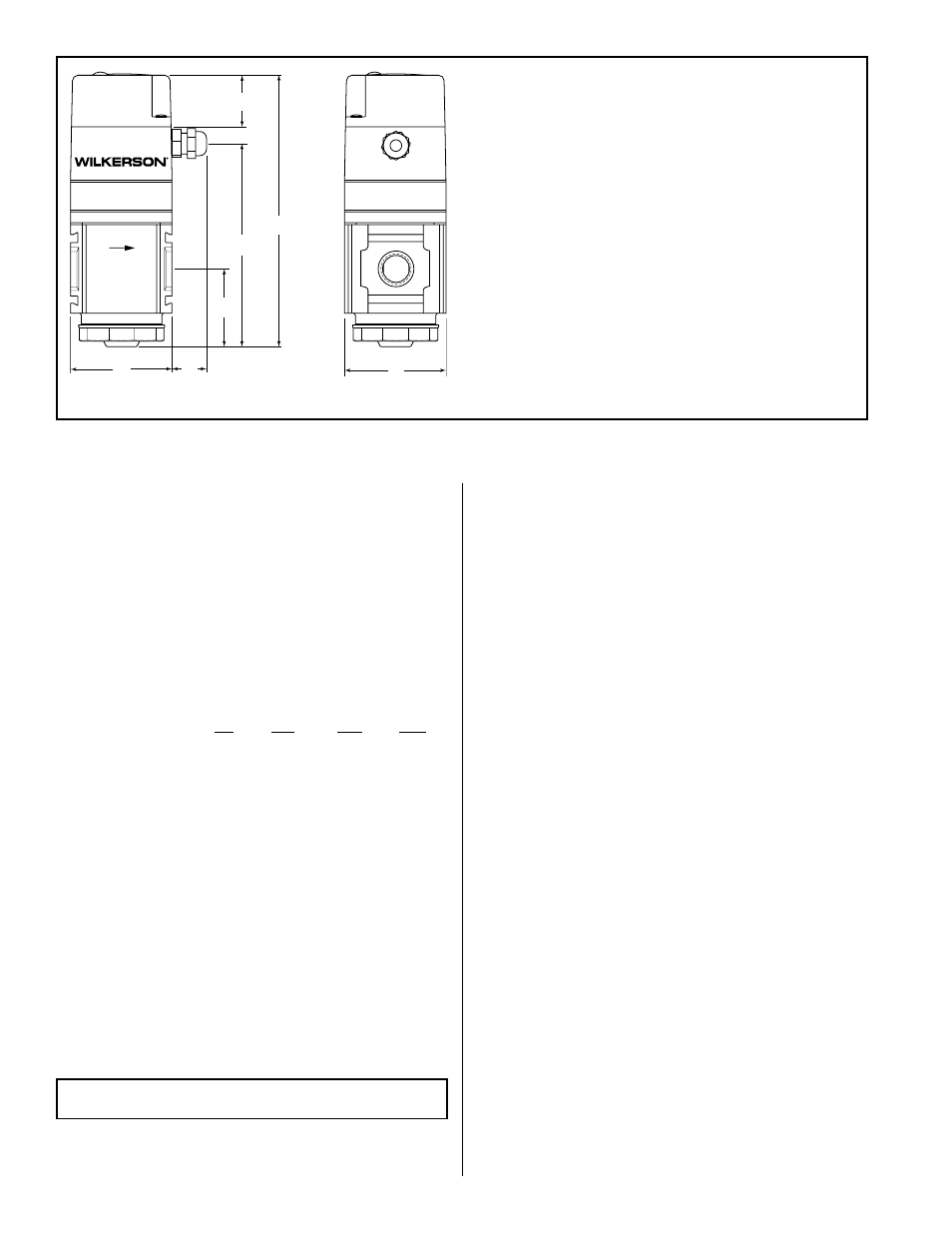

Inches

millimeters

Dimensions

Models

A

B

C

D

E

F

G

ER1

6.31

4.71

2.35

.79

1.79

2.35

1.20

160

120

60

20

45

60

30

ER2

6.31

4.71

2.88

.79

1.79

2.88

1.20

160

120

73

20

45

73

30

Front View

Side View

Troubleshooting

Unit Fails to Operate

1) Verify supply voltage

2) Verify control voltage

3) Intake valve or controller failure

4) Apply 12 VDC to valve and listen for slight

click indicating valve is working

5) Replace control board

Unit Remains Pressurized

1) Verify control voltage

2) Exhaust valve or controller failure

3) Apply 12 VDC to valve and listen for

slight click indicating valve is working

4) Replace control board

LCD Fails to Display Pressure

1) Verify supply voltage

2) Verify that ribbon cable is secure on both ends

3) Have dealer check LCD board and replace if necessary

4) Replace control board

Unit Has Constant Leak or is Unstable

1) Inspect and clean bottom valve seals and

lubricate bottom valve

2) Inspect and clean diaphragms

A

B

E

D

C

F

G