Wilkerson M42 User Manual

Installation and maintenance sheet

INSTALLATION

1.Purge downstream air line of oil.

2.Install the unit with the air flowing in the direction indicated by

the arrow on the body and/or the DP2 indicator.

3.A drain line with 1/2" NPT connection may be attached to the drain port if

desired. (The optional X02-04-FM0 external drain requires a 1/8" NPT

connection). Drain line should be 1/4" tubing or larger, as short as

possible, and crimp free.

4.Maximum inlet pressure and operating temperature ratings are:

units with DP2: 150 psig (10,3 bar) 150°F (66°C); units with DP3: 200 psig

(13,7 bar), 150°F (66°C); units without DP2 or DP3: 200 psig (13,7 bar),

175°F (80°C).

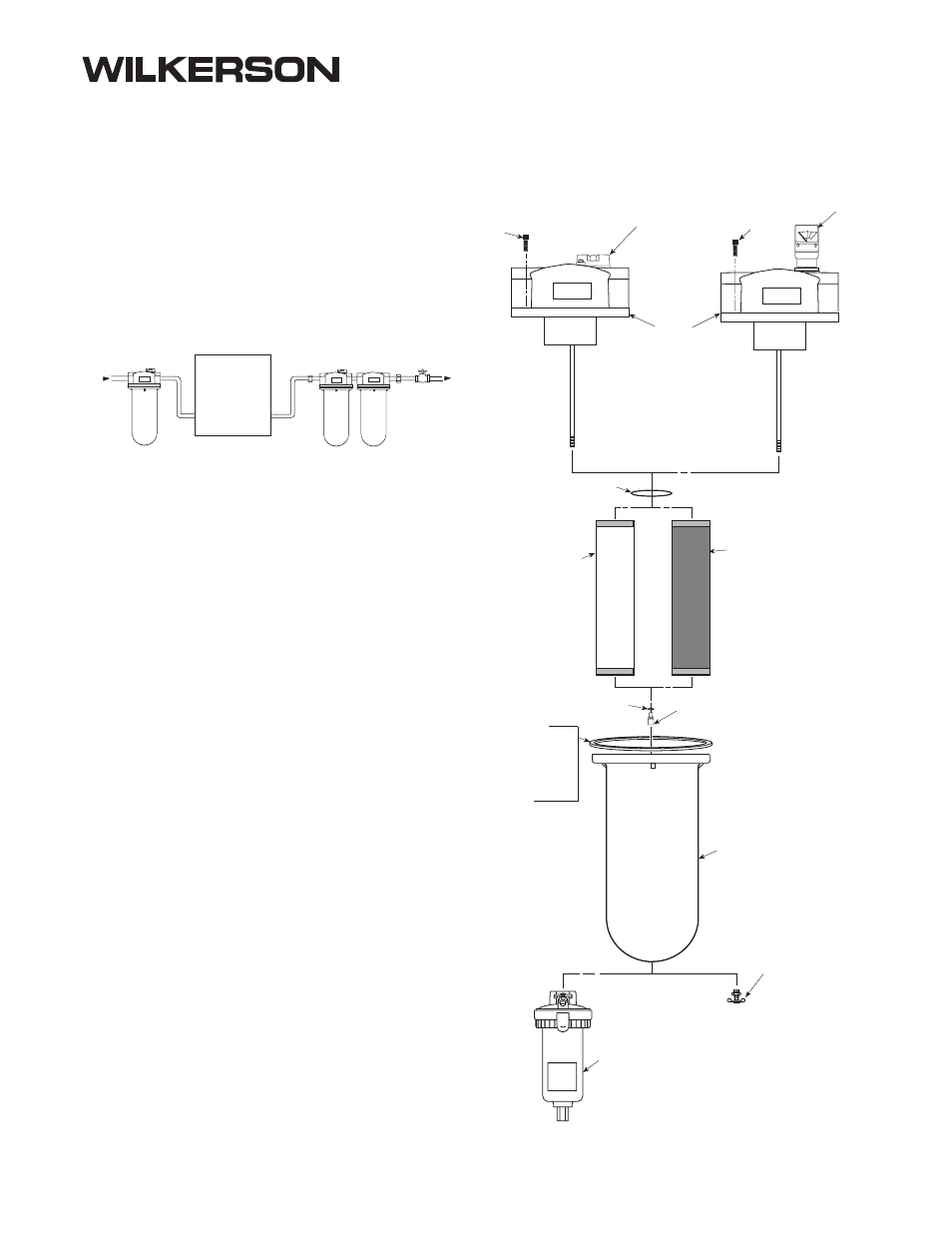

TYPICAL INSTALLATION (not to scale)

A. PREFILTER - It is recommended that a Wilkerson “B1” Element

coalescing prefilter (particle removal down to 1.0 micron; maximum

downstream remaining oil content 0.5 ppm/wt.) be installed upstream from

the high efficiency coalescer filter to prolong element life.

B. AIR DRYER - (Refrigerative or Desiccant). An air dryer is recommended

if water vapor condensation is a problem.

C. HIGH EFFICIENCY COALESCER FILTER - It is recommended that a

Wilkerson “C” element coalescer filter (particle removal down to 0.01

micron; maximum downstream remaining oil content 0.01 ppm/wt.) be

installed to protect the compressed air system from oil and particulate

contamination.

D. OIL VAPOR FILTER - The Type D element filter (maximum downstream

remaining oil content 0.003 ppm/wt.) is an adsorption type for removing oil

vapors, oil-associated odors, whether petroleum base or synthetic base,

and nearly 100% of any remaining solid contaminants.

E. DIFFERENTIAL PRESSURE INDICATOR/GAUGE - Maximum

recommended pressure drop across coalescing filters is 7 psi (0,5 bar).

This can be monitored by using the Wilkerson DP2 differential pressure

indicator (standard) or the DP3 differential pressure gauge (optional).

F. VALVE - Do not use a valve or shutoff device in conjunction

with a coalescing filter that will allow a momentary or surge pressure

drop greater than 50 psig (3,4 bar). To avoid high surges which can

either ruin the element or momentarily allow downstream contamination,

use a slow-opening type valve.

MAINTENANCE

1.The element operates effectively when it is saturated. The element's

useful life will end only when the DP2 pressure indicator is completely red

or when the DP3 reads 7 psi (0,5 bar). The element cannot be cleaned or

reused and must be replaced at the end of its useful life.

2. IF THE UNIT HAS A MANUAL DRAIN, DRAIN THE UNIT ONCE EVERY 8

HOURS MINIMUM. If the unit is equipped with an external automatic drain

clean the screen around the drain. Clean screen by blowing it off with an

air blow gun.

3.When the bowl becomes dirty, clean by wiping with a dry, clean cloth.

4.Before placing the unit in service, make sure that the bowl is properly

reinstalled, and securely bolted in place.

ELEMENT

O-RING

FILTER

ELEMENT

TYPE B1 AND

TYPE C

(INCLUDES

O-RINGS)

FILTER ELEMENT

TYPE D

(INCLUDES

O-RINGS)

SCREW

NNR

kPa

x

100

bar

(psi)

0.35

(5,0)

0.7

(10)

.P

DP3

DIFFERENTIAL

PRESSURE

GAUGE

(OPTIONAL)

PRESS

TURN

X02-04-FM0

AUTOMATIC DRAIN

(OPTIONAL)

RETAINER NUT

NNR

O-RING

BOWL

NNR

PETCOCK

NNR

SCREW

NNR

DP2

DIFFERENTIAL

PRESSURE

INDICATOR

(STANDARD)

BOWL

GASKET

NOTE: GASKET

GROOVE IS IN

THE BOWL

FLANGE

COVER

NNR

83-286-000 REV REL 8/95

Printed in the U.S.A.

NNR=NOT NORMALLY REPLACED

REPAIR KITS AND REPLACEMENT PARTS

M42-0A Type D Element Kit (carbon adsorption)

(includes filter element and o-rings) ..................................MXP-95-563

M42-0A Type C Element Kit (.01 ppm/wt)

(includes filter element and o-rings)...................................MTP-95-560

M42-0A Type B1 Element Kit (.5 ppm/wt)

(includes filter element and o-rings) ..................................MSP-95-874

M42-0B Type D Element Kit (carbon adsorption)

(includes filter element and o-rings) ..................................MXP-95-564

M42-0B Type C Element Kit (.01 ppm/wt)

(includes filter element and o-rings)...................................MTP-95-561

M42-0B Type B1 Element Kit (.5 ppm/wt)

(includes filter element and o-rings) ..................................MSP-95-875

(Replacement kits and parts continue on back page)

INSTALLATION AND

MAINTENANCE SHEET

Coalescing Filter Model M42

with Variations and Accessories

®

OPERATIONS

A

B

C

D

F

E

E