Installation, Description – Wilkerson ER2 User Manual

Page 2

!

!

E

+

–

P

Sensor

Command

Signal

0–10 VDC

4–20 mA

Comparator /

Controller

Power

Supply

12–28 VDC

OUT

IN

Installation

Mechanical Installation

1.

Refer to the WARNING above.

2. Do not install until you have read the entire product

information sheet.

3. Minimum inlet pressure ............................. 20 psig (1.4 bar)

Maximum inlet pressure ........................ 150 psig (10.3 bar)

Minimum temperature ..................................... 40°F (4.4°C)

Maximum temperature ................................ 125°F (51.6°C)

4. Prior to installation, ensure that the pressure in the line

where this product is to be connected is at atmospheric

pressure 0 psig (0 bar).

5. Install a quality Wilkerson filter upstream of the unit for

maximum trouble free operation.

6. Install with the air flow in the same direction as the arrow on

the unit. DO NOT restrict the air flow with undersize piping

or fittings, unless maximum flow is not required.

Electrical Connection

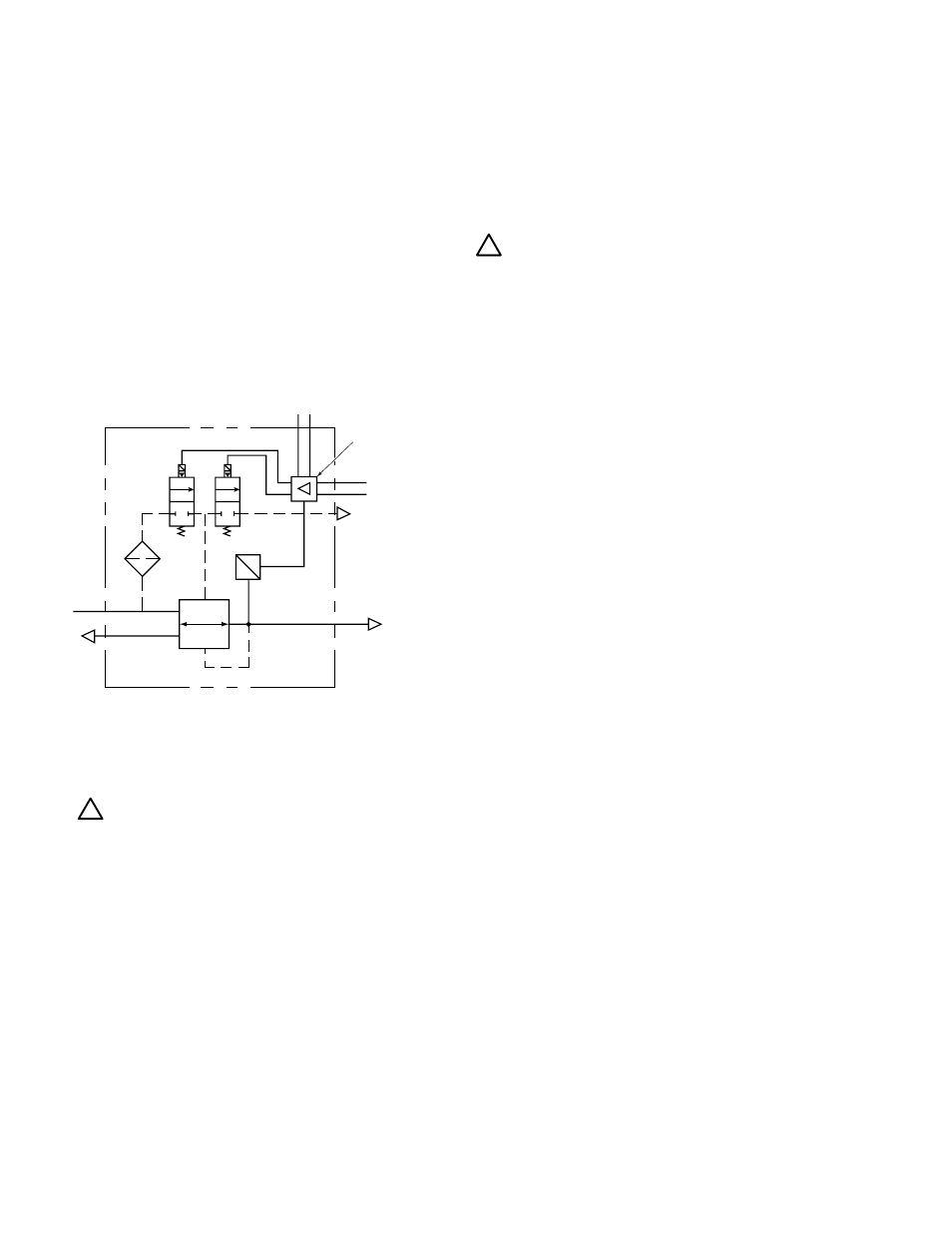

Since the same control board is used for all control signal options

(Figure 3A) to provide maximum flexibility at minimum cost, the

board must be configured for each particular application by

positioning the jumpers correctly and wiring correctly. This is a

very important step to ensure optimum performance.

Determine what signal you will be using to control the regulator

and follow the instructions for that application. The control

board must be configured and wired accordingly.

Caution: Improper wiring may result in damage to the unit.

To configure the unit for the desired option, and to connect the

external wires to unit, remove the housing by removing the two

screws on top of the unit

(Figure 4). Carefully lift the housing

off and lay it to one side, making sure not to damage the ribbon

cable that connects the control board to the LCD board.

The jumpers should be configured correctly from the

factory for the configuration ordered and will only need to be

changed if once the unit is received, the user decides on

different control signal, pressure display or pressure range.

(Refer to Figure 2)

Option #1 Sensor feedback signal

Internal sensor ................................. Jumper on position #5

Option #2 LCD display mode

a. psig ............................................... Jumper on position #4

b. bar ................................................ Jumper off position #4

NOTE: If using bar option, be careful not to lose jumper.

Option #3 Control signal

a. 0–10 VDC .................................... Jumper on position #1

or

b. Internal control ............................. Jumper on position #2

or

c. 4–20 mA ....................................... Jumper on position #3

NOTE: Only one control signal at a time can be used.

Option #4 Pressure Range

Each control board has two pressure ranges available and

can be selected by the Jumper on position #7

The high range board can be configured for either:

a. 0–90 psig (0–6 bar) ..................... Jumper on position #7

or

b. 0–125 psig (0–8,6 bar) ................ Jumper off position #7

The low range board can be configured for either:

a. 0–30 psig (0–2 bar) ..................... Jumper on position #7

or

b. 0–60 psig (0–4 bar) ..................... Jumper off position #7

First feed the cable through the strain relief provided and remove

the retaining nut for the strain relief. Now feed the wires through

the hole in the control board housing, slide the retaining nut over

the wires and secure the strain relief to the housing making sure

to have the required amount of wire to connect them to the

terminal block. Once this is completed you can connect the wires

to the terminal block as the following describes.

Now, with the unit configured to the desired options, the

external electrical connection of the unit can be done. This is

accomplished by securing the wires directly to the control

board terminal block on the upper right hand side of the unit

(Figure 3). It is recommended that a shielded cable with the

required number of wires for your application be used to

connect the unit if using an external control and monitor signal.

The shield should be connected to the supply ground and not

to the unit. If using the internal control, only a supply voltage

will be required, although the monitor signal can be used.

Description

The ERl and ER2 are high flow electro-pneumatic regulators

capable of delivering accurate pressures over a wide range of

flows. The units have a variety of port sizes, ranging from 1/4

inch to 3/4 inch NPT and “G” series threads and use the

convenient Wilkerson 18/28 series modular mounting. The ER

series consists of an integral system of two control valves and

feedback transducer to provide closed-loop control. In addition

the units come with an optional LCD display that displays the

outlet pressure in psig or bar.

The ER series regulators are controlled by either a 0–10 VDC

or 4–20 mA external input signal, or by internal adjustment for

stand- alone operation. The control signal is compared to the

output signal of the internal pressure sensor and the regulator

adjusts the pressure accordingly. The pressure sensor signal

is also an output of 0–10 VDC for external monitoring.