Service, Service kits available – Wilkerson P12 User Manual

Page 2

!

Service

CAUTION:

SHUT OFF AIR SUPPLY and exhaust the primary and

secondary pressure before disassembling regulator unit.

(Turning the knob counterclockwise reduces regulator’s

setting, but does not vent downstream pressure on non-

relieving regulators.)

CAUTION:

Lubricate parts with a mineral based oil / grease or silicone free

grease. DO NOT use synthetic oils / greases such as esters.

A. Use the following procedure to service Diaphragm and

/ or Control Spring:

1. Disengage the adjusting knob by pulling upward. Turn

adjusting knob counterclockwise until the compression is

released from the pressure control spring.

2. Unscrew the threaded collar and remove the bonnet

assembly. Next, disassemble, clean, and carefully inspect

parts for wear and/or damage. If replacement is necessary,

use parts from service kits.

3. Lubricate o-ring and lip seals with grease (supplied with kits).

4. Install diaphragm assembly into bonnet. Then install bonnet

assembly to body and tighten threaded collar per Figure 1.

B. Servicing the Valve Assembly-

1. Exhaust system air pressure as previously described. Then

remove bottom cap by unscrewing it from body. Next, remove

valve assembly, o-ring, cap o-ring and valve return spring.

2. Next, disassemble, clean, and carefully inspect parts for

wear and/or damage. If replacement is necessary, use parts

from service kits.

3. Lubricate o-ring and sliding surfaces using grease supplied

with service kit.

4. Install parts as shown in Figure 1.

5. Lubricate cap o-ring and install it in o-ring groove on cap.

Then screw cap into body until the cap bottoms out in body

(See Figure 1).

6. Turn on air supply and adjust to desired secondary pressure

as described in the Operation section.

Turn on air pressure and check regulator for leakage. If leakage

occurs, DO NOT OPERATE — conduct repairs again.

If you have questions concerning how to service this unit, contact

your local authorized dealer or your customer service representative.

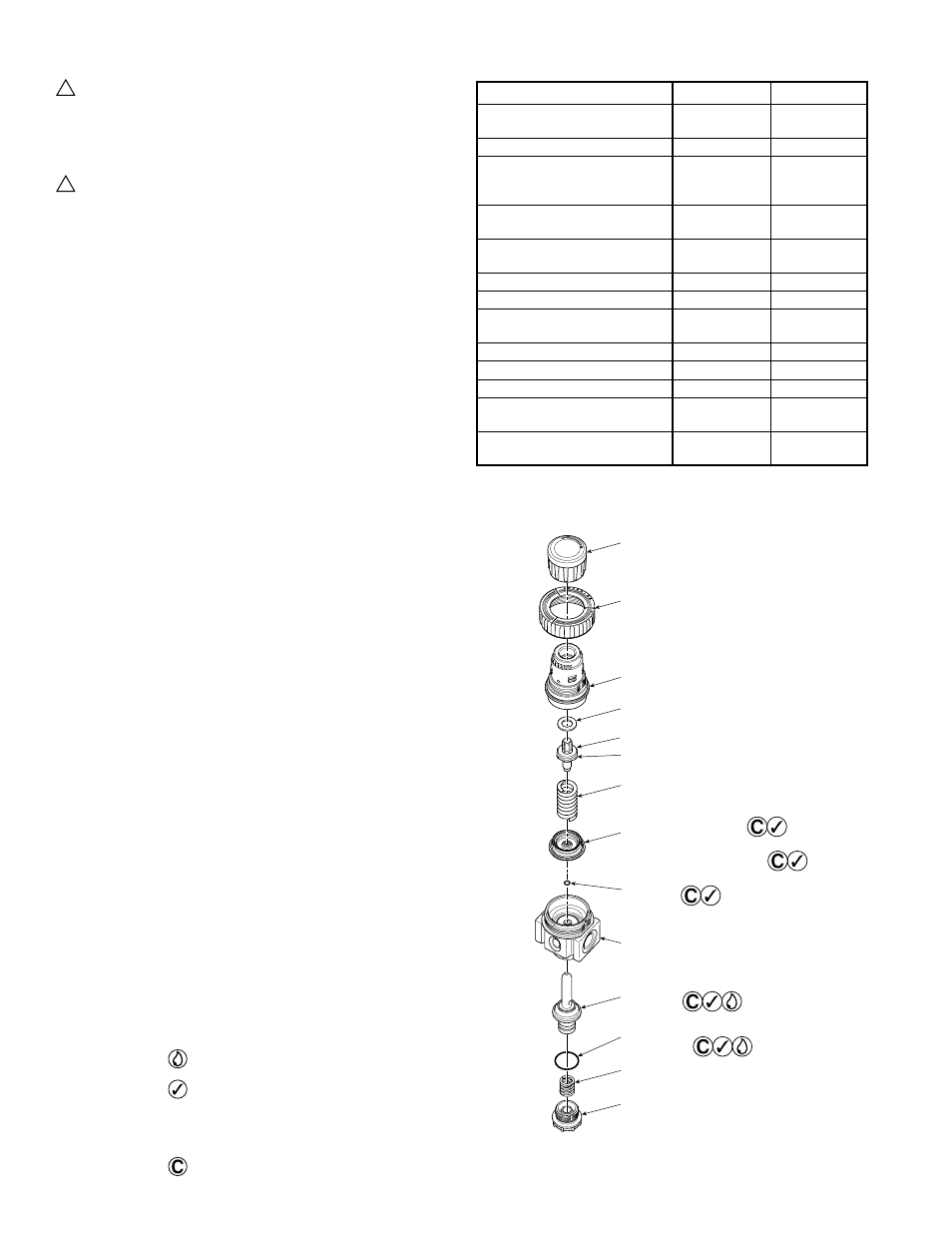

1/4" and 3/8" R12 Regulator, and 1/4" and 3/8" P12 Precision Regulator

83-956-000

Figure 1:

R12 and P12

Regulators

Knob

Collar

(Hand tight

plus 1/4 turn)

Bonnet

Washer

Adjusting Screw

Drive Nut

Control Spring

Spring,

Valve Return

O-Ring,

Bottom Cap

O-Ring,

Vent Seal

(Not used on 27RC)

Diaphragm Assembly

(Includes Upper Diaphragm Plate

& Lower Diaphragm Plate)

Bottom Cap

Torque:

2.3 to 2.8 Nm

(20 to 25 in. lb.)

Valve

Assembly

Body

Service Kits Available

Description

R12

P12

Air Pilot Conversion

(Relieving)

GRP-96-350

—

Bonnet Assembly

RRP-96-308

—

Gauges:

Low Pressure

RRP-96-664

RRP-96-664

0 to 414 kPa (0 to 60 PSIG)

Low Pressure

0 to 207 kPa (0 to 30 PSIG)

RRP-96-663

RRP-96-663

Standard Pressure

0 to 1103 kPa (0 to 160 PSIG)

RRP-96-665

RRP-96-665

Mounting Bracket Kit

GPA-96-313

GPA-96-313

Regulator Control Knob

RRP-96-300

—

Springs:

862 kPa (125 PSIG)

RRP-96-301

RRP-96-301

414 kPa (60 PSIG)

RRP-96-302

RRP-96-302

206 kPa (30 PSIG)

RRP-96-303

RRP-96-303

1379 kPa (200 PSIG)

RRP-96-304

RRP-96-304

Non-Relieving

Regulator Repair Kit*

RRP-96-307

—

Relieving Regulator

Repair Kit*

RRP-96-306

RRP-96-305

*Grease in kit is silicone free

Lightly grease with provided lubricant.

Inspect for nicks, scratches, and surface

imperfections. If present, reduced service

life is probable and future replacement

should be planned.

Clean with lint-free cloth.

!