Servicing regulator, Servicing filter element, Parts identification list – Wilkerson B03 User Manual

Page 2: Service kits available

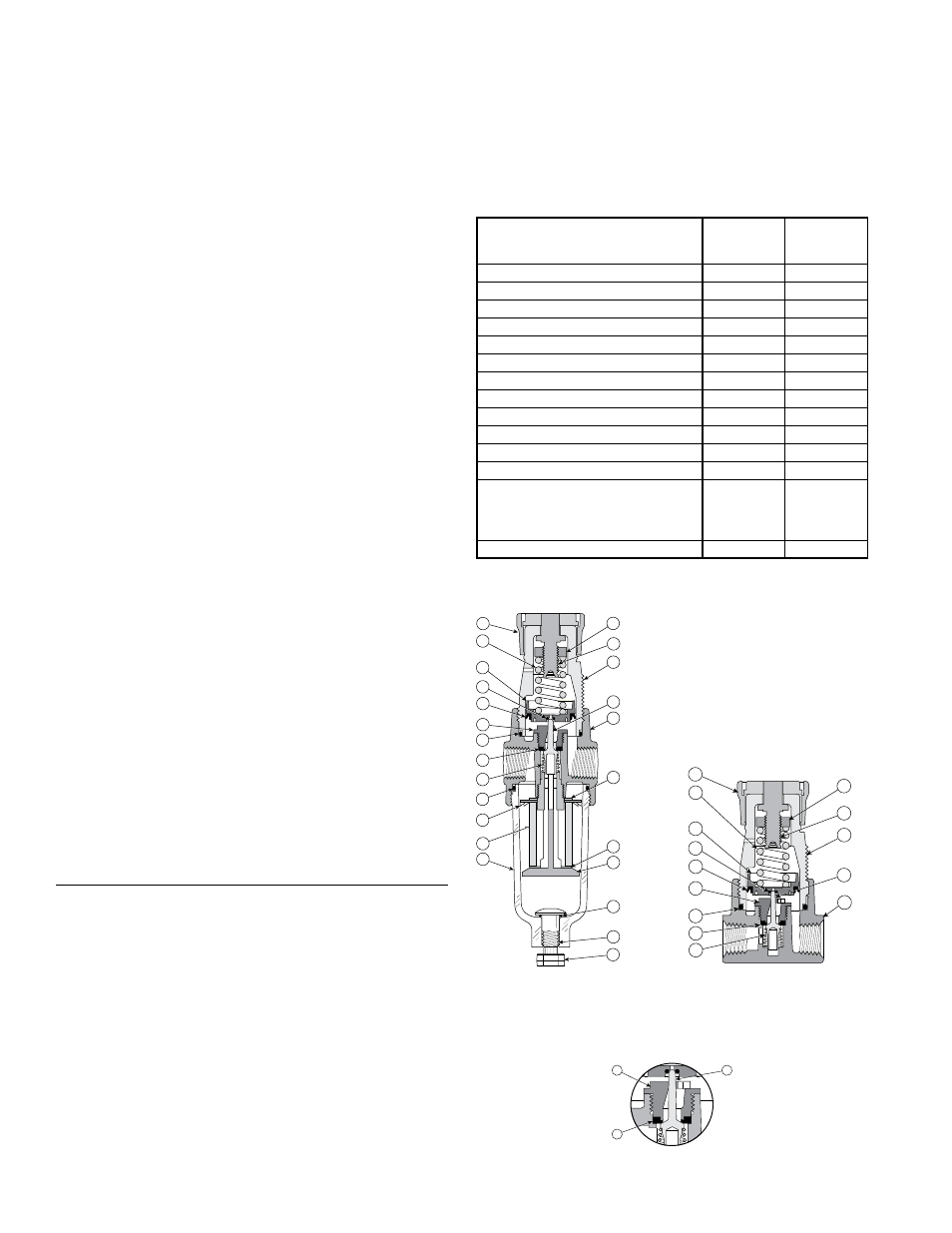

Miniature Filter / Regulator, Miniature Regulators 1/8" and 1/4" Ports

1R602

Servicing Regulator:

Note: See Figure 1, 2, & 3 to aid with this procedure.

1. Unlock the adjusting knob by pulling upward (with the unit in an upright position.)

Then turn adjusting knob counterclockwise until compression of the control spring

has been removed.

2. Remove the bonnet from body. Then remove o-ring (7), piston, lip seal (9), and

control spring to service the bonnet subassembly. Unscrew seat (8) to service the

poppet (17), return spring (5), and /or poppet seal (6).

Note:

On filter / regulator units, the poppet assembly & poppet return spring may be

accessed by removing filter element.

3. Clean old grease from unit and inspect seals for sign of wear (nicks, cuts, and

scratches). Repair kits are available which contain the parts which are typically

replaced.

4. Apply a light film of grease to all seals and sliding surfaces using the grease packet

supplied with repair kit.

Note:

Refer to Figures to determine the correct position and orientation of the various

parts during assembly.

5. Install lip seal onto piston with the lips of the seal facing away from the support

flange. Then insert control spring and piston assembly into bonnet.

6. Place poppet return spring and poppet assembly into bore, followed by poppet

seal and seat.

7. Tighten seat to body from 0.9 to 1.1 Nm (8 to 10 in-lbs) of torque. Tighten bonnet

onto body from 5.6 to 7.3 Nm (50 to 65 in-lbs) of torque.

8. Make sure that the control spring is still uncompressed before turning on the

air supply. Turn on air supply, then slowly adjust the knob clockwise to increase

downstream pressure until the desired pressure has been reached.

9. To decrease regulator pressure setting, always reset from a pressure lower than

the final setting desired. For example, lowering the secondary pressure from 550 to

410 kPa (80 to 60 PSIG) is best accomplished by dropping the secondary pressure

to 350 kPa (50 PSIG), then adjusting upward to 410 kPa (60 PSIG).

10. When the desired secondary pressure setting has been reached, push the

adjusting knob down to lock it.

11. Check for leaks. If leaks occur, shut off the air supply, exhaust system air pressure,

and make necessary adjustments to eliminate leakage.

Servicing Filter Element:

Note: See Figure 1 to aid with this procedure.

1. Unscrew threaded bowl and element holder. Then remove filter element, deflector,

and gaskets.

2. Clean all internal parts, bowl, and body before re-assembling unit. See

Polycarbonate bowl cleaning section.

3. Install deflector, filter element, and gaskets.

4. Attach element holder. Torque 0.9 to 1.4 Nm (8 to 12 in-lbs).

5. To assist with retaining bowl’s o-ring while installing bowl, lubricate the o-ring (with

a mineral based oil or grease). Then place it on the bowl.

6. Screw bowl into body until it is stopped by body; then back off bowl

1/8 turn.

7. Apply pressure to the system and check for leaks. If leaks occur, shut off the air

supply, de-pressurize the system and make necessary adjustments to eliminate

leakage.

If you have questions concerning how to service this unit, contact your local

authorized dealer or your customer service representative.

Parts Identification List

Item# Description

1 Bowl (Miniature Filter Regulator)

2 Filter Element (Miniature Filter Regulator)

3 Deflector (Miniature Filter Regulator)

4 O-ring (Miniature Filter Regulator) - bowl to body

5 Poppet Return Spring

6 Poppet Seal

7 O-ring - body to bonnet

8 Seat

9 Lip Seal - piston to bonnet

10 O-ring - piston to poppet (Miniature Regulator & Filter / Regulator

relieving units)

11 Piston (relieving shown)

12 Control Spring

13 Knob

14 Hex Nut

15 Adjusting Screw

16 Bonnet

17 Poppet (Miniature Regulator & Filter / Regulator)

18 Body

19 Gasket (Miniature Filter Regulator) - deflector to body

20 Gasket (Miniature Filter Regulator) - element holder to filter element

21 Element Holder (Miniature Filter Regulator)

22 O-ring (14E) - body to drain

23 Twist Drain (Miniature Filter Regulator)

24 Twist Drain Knob

Service Kits Available

The following service kits contain the appropriate seals and parts necessary for

ordinary field service.

FIGURE 2: Miniature Regulator -

Un-balanced, Relieving Unit Shown

FIGURE 3: Detail of Poppet Seal

6

8

17

13

14

15

16

17

18

12

11

10

8

7

5

6

9

FIGURE 1: Miniature Filter /

Regulator -

Un-balanced, Relieving

Torque:

Finger Tight

6

4

3

9

10

11

7

2

1

8

24

5

12

13

17

14

19

16

20

22

23

21

18

15

Description

Miniature

Filter /

Regulator

Miniature

Regulator

Adsorber

PS452

PS452

5 Micron Element Kit

PS403

N/A

40 Micron Element Kit

PS401

N/A

Metal Bowl w/Manual Drain

PS447B

N/A

Metal Bowl w/Automatic Drain

PS451B

N/A

Mounting Bracket Kit* (plastic ring)

PS417B

PS417B

Mounting Bracket Kit* (aluminum ring)

PS466

PS466

Panel Mount Nut - Metal*

P01531

P01531

Piston & Poppet Kit - Unbal. Rel.

PS426

PS426

Piston & Poppet Kit - Unbal. Non-Rel

PS428

PS428

Polycarbonate Bowl w/Manual Drain

PS404

N/A

Polycarbonate Bowl w/Automatic Drain

PS408B

N/A

Springs: 1-30 PSIG Range

1-60 PSIG Range

2-125 PSIG Range

1-15 PSIG Range

P01175

P01174

P01173

P01176

P01175

P01174

P01173

P01176

Twist Drain Knob

P05117

*Tighten panel mount nut 2.8 to 3.4 Nm (25 to 30 in-lbs) of torque.