Top Flite Wristcrat User Manual

Page 9

tubing, clean each end with a #11 blade and care-

fully insert it into the stab pivot hole just cleared

out, do not glue Now assemble the wing to the

fuselage followed by attaching the stabilizer

halves to the fin, just press in place for now What

we're going to check for now is alignment We

want to view the airplane head-on at a bit of a

distance Place it on a table, facing you, and back-

off a few paces, sighting directly at the front Is the

wing sitting properly on the fuselage? Are the

stabs tilted in relationship to the wing/fuselage or

do they look "right"? If everything seems to line-

up, we can proceed to finish sheeting the top, rear

of the fuselage If it doesn't, we need to know

which way to twist the fin to make everything line-

up properly because once the top rear sheeting is

installed, it "locks" the fuselage firmly in place

thus making any such corrections extremely dif-

ficult, if not impossible.

If the alignment appears to be OK, remove the stab

halves, leave the wing in place and carefully cut

and glue the 1/16" balsa sheet (applied crossgrain,

as shown) top, rear decking in place back to the

leading edge of the fin However, if some align-

ment is needed by having to pull the top of the fin

left or right, now is the time to do it, before apply-

ing the top, rear sheeting This is how it's done Set

the assembled airplane on a large, flat table Place

weights (magazines, lead, whatever) on top of the

wing center section, thus holding it firmly in place.

Again sighting directly at the front of the model,

determine which way the fin has to be tilted Pull

off a long length of masking tape and stick it to the

top of the fin Pull against the tape until the fin is in

the right position and stick the other end to the

table, thus preventing the fin from shifting Once

satisified that it is now properly aligned, cut, fit

and glue the top, rear sheeting in place as earlier

described Let the sheeting dry before removing

the masking tape from the fin and you'll find that

the fin is now properly aligned Disassemble the

wing and stabilizer halves from the fuselage Use

your sanding block to now sand the top, rear

sheeting and the forward radio hatch and nose

block piece flush with the fuselage sides You can

also now sand the top forward hatch and nose-

block contours to shape as shown on the plans, no

need to round corners yet.

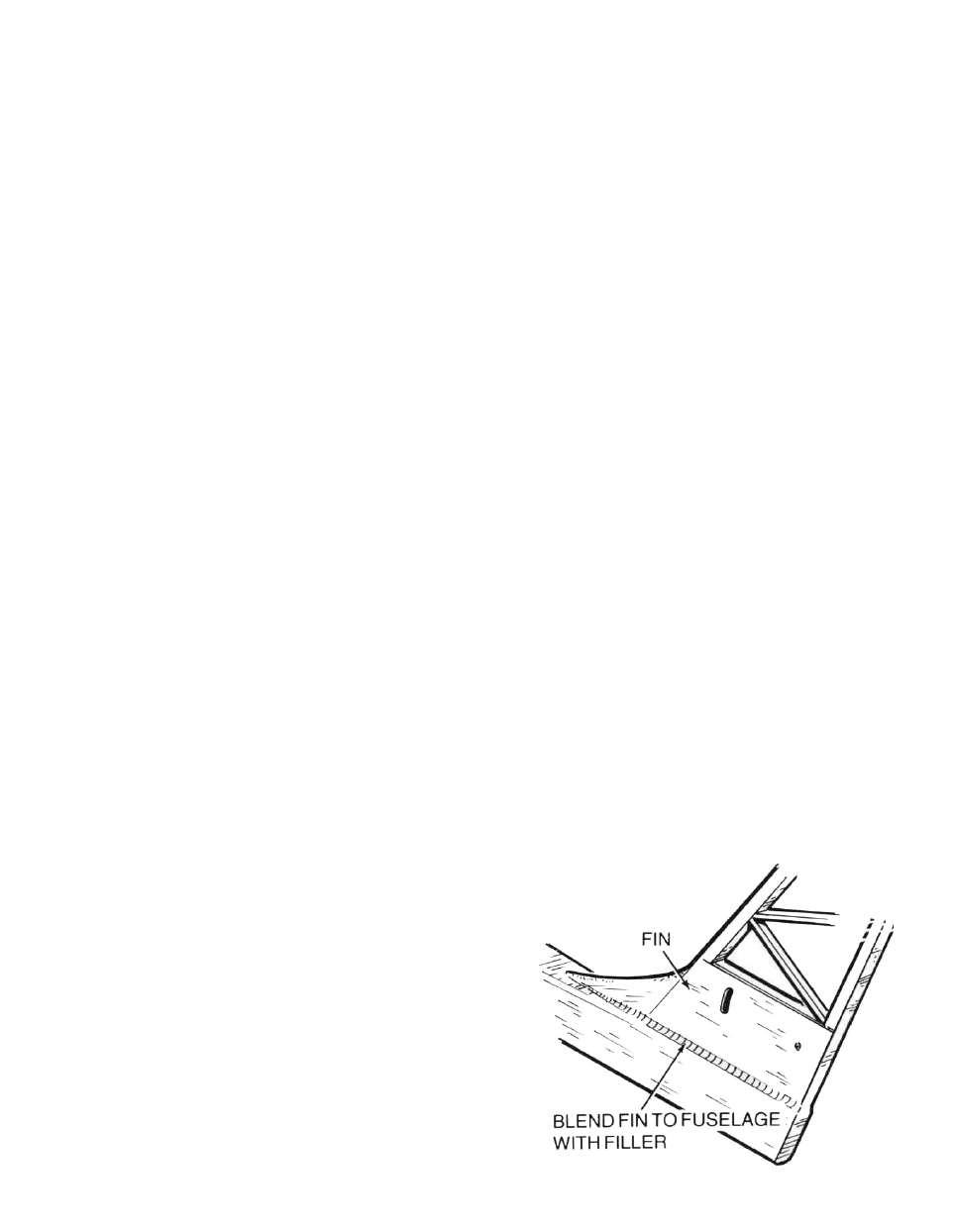

D 17. From your parts bag, locate the 1/4" shaped

fin/fuselage fairing Use your sanding block to ad-

just the angles if needed and glue in place As

shown, this is now trimmed to fair the fin leading

edge into the top, rear of the fuselage

Finally, push the 1/4" length of aluminum tubing

that's in the rear pivot hole about halfway out, app-

ly just a bit of adhesive to its outer surface

(5-minute epoxy or slow cure CA) and push it back

in place in the fin.

With the exception or contouring and final san-

ding, your fuselage should be complete

FINAL ASSEMBLY

Its often been said that the difference between a good

model and a great one is sandpaper and the willingness

and ability to use it This is the point in construction that

can literally make or break the performance and the look

of your model Since the WRISTOCRAT is an obvious

candidate for use of Monokote™, you would do well to

keep in mind that the surface preparation of the wood

will dictate the finished, covered look of your model

When we reference the use of "filler" in the following

text, we have found that some of the best products to

use are those such as "MicroFill" or Model Magic Filler

or something similar These products dry quickly, are

very light and Monokote goes over them nicely. Look for

these at your local retailer

Let's start with the fuselage since the other components

should, by now, be sanded and about ready to use

D 1. Note the lower left corner of Cross Section C-C on

the plans This demonstrates about the correct

amount of radius that can be and should be sand-

ed into the fuselage bottom As this sanding

radius moves aft, toward the fin post and the

fuselage diminishes in width, the result will be

pleasant looking oval shape Next, sand the radio

hatch and nose block sections to a nice, rounded

look right down to the nose Using a rougher grit of

paper at first, followed by something like #220 will

do the job nicely The last section to tackle is the

top, rear of the fuselage, back to and including the

fin fairing and fin leading edge Take every effort

needed to sand this structure to the point that it

looks and feels like one piece You will note that

where the T-1 fin sides meet the fuselage sides,

there is a disparity in wood thickness, resulting in

a kind of "lip" On our prototypes, we handled this

by sticking a length of masking tape, lengthwise,

about 3/16" above this joint, on T-1 Then we careful-

ly sanded down the fuselage side(s) to as close to

T-1 as possible (the masking tape was there to pro-

tect T-1 in case we got too close) Then with the

tape still in place, we used filler to "fair-in" this

joint, feathering the material carefully When the

filler was dry, the tape was removed and we used

very light sandpaper to finish feathering the joint.

9