Top Flite Wristcrat User Manual

Page 6

D 1. Remove the two fuselage sides from their die-cut

sheet. Tape, pin or clamp them together and use a

sanding block to lightly sand their edges, thus

matching them exactly. Now lay one of the

fuselage sides directly over the side view on the

plans and accurately mark the location of the F-3

lite-ply former. Also mark the location of the end

of the top 1/8" sq. balsa longeron at the leading

edge of the fin — this will be at an angle, use a

straight edge. Lastly, mark the location of the for-

ward end of the bottom 1/8" sq. longeron, where it

butts against the noseblock. Duplicate these

marks on the remaining fuselage side —

remember that you need a right and a left

fuselage side!

D 2. Glue the two F-2 balsa doublers in place on the in-

side faces of each fuselage side, matching its top

contours to those of the fuselage sides. Glue the

top and bottom 1/8" sq. balsa longerons in place

after first trimming their ends to fit the marks

made earlier. Remove the fuselage sides from

your work surface and pin, tape or clamp them

together again. Use your sanding block to once

again make sure they are identical. While they're

together, check the trimmed ends of each

longeron to be sure they are matched accurately.

Set these aside for now.

D 3. Using the 3/16" sq. and 3/32" x 3/16" balsa stock provid-

ed, build the fin frame directly over the plans.

Take your time and ensure that each of the re-

quired joints is accurate and well-matched.

Remove the frame from your work surface and

use a sanding block to lightly smooth out the

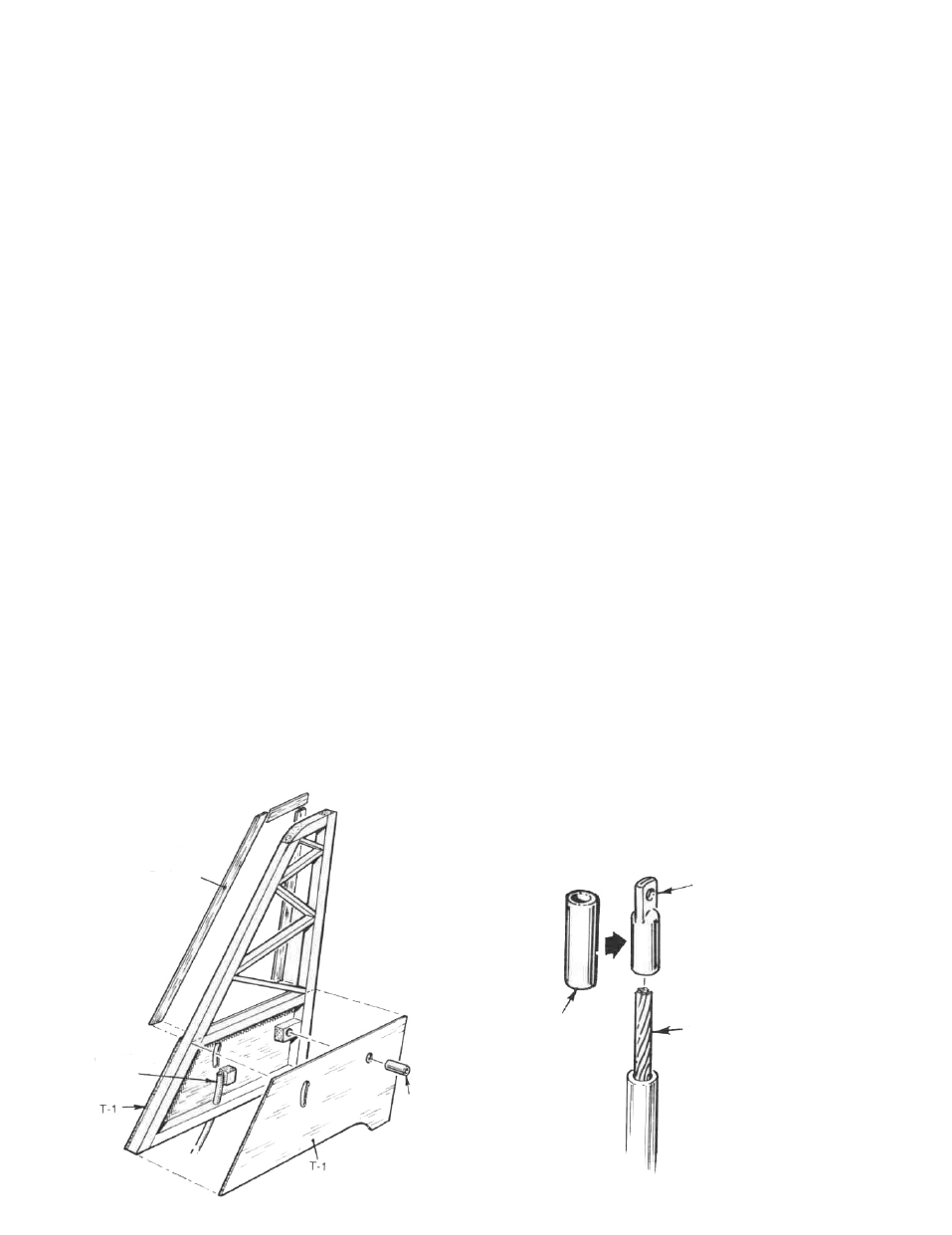

sides and edges. Remove one of the T-1 fin sheets

from its die-cut sheet. This can now be glued in

place to the right side of the fin frame, as shown

on the plans. Do this operation accurately and

with a minimum amount of glue.

D 4. The right side of the fin frame, outer 3/16 "edges on-

ly, is now capped with 1/32 " x 3/16" strips cut from the

1/32" X 3/16" BALSA

LAMINATED EACH SIDE

OF FRAME

CABLE GLUED TO

BALSA BLOCK

1/16" I.D.

ALUMINUM

TUBE

open, center area of die-cut sheet #RC-35-5. This

carries through the increased thickness of the fin

created by the T-1 fin sheet. Note the "+" mark

toward the rear of the T-1 fin sheet. Use a 3/32 "drill

to accurately make a hole at this mark. This hole is

referred to as the stab pivot hole. As shown on the

plans, glue a short length (about V will do) o f 3/16"

balsa stock directly over the 3/32" dia. hole just drill-

ed through T-1.

D 5. Take the right fuselage side and pin or weight it in

place carefully over the plan. Place the fin

assembly on the fuselage side, at the rear to check

its fit and trim carefully, if needed. Place a scrap

piece o f 3/32" stock underneath the fin frame, above

the fuselage side, to bring the fin level. Carefully

glue the fin frame assembly to the fuselage side-

pin or weight in place and allow to dry.

D 6. From your kit box locate and remove one of the

braided metal drive cables and one of the outer

cable housing tubes. Use a piece of sandpaper to

lightly scuff the outer surface of the plastic tube.

As shown on the plans, the stabilizer cable drive

tube is going to be glued directly to the right

fuselage side and up into the lower fin, directly

beneath the oval stab drive hole in T-1. Position the

forward end of the stab drive tube just ahead of the

F-3 former location and glue it in place to the right

fuselage side, just beneath the F-2 doubler and

about 1-1/2" back from the F-3 location. (An

adhesive such as Pacer's Slo-Zap CA is great for

this operation.) Repeat this procedure all the way

back to just beneath the fin, noting that the stab

drive tube gently arcs down to the fuselage bottom

as it is positioned rearward. Before making the

bend up to the oval hole in T-1, load the tube with

the inner braided cable. Now make the bend up to

the hole and hold this assembly in position. Try

moving the cable back and forth; it should move

easily without binding. Once satisfied, glue the

short length o f 3/16" sq. balsa in place as shown to

hold the tube and then glue the tube to this block.

Use a razor blade to trim off the tube end after re-

moving the cable.

BRASS TUBE

FLATTEN END THEN DRILL

1/16" DIA. HOLE

STABILIZER CONTROL CABLE.

SOLDER INTO BRASS TUBE

6