Top Flite Wristcrat User Manual

Page 7

D 7. As shown on the plans, the stab drive fitting itself

is nothing more than a short length of 1/16" I-D.

brass tubing (

1

1/2" provided) which has about 1/8" of

it's length flattened in a vise. This "flat" is then

drilled with a 1/16" dia. hole. The other end of this

tube is trimmed in length to leave only about 1/8"

left that is still "tube". This fitting is then soldered

to the end of the stab drive cable. Do all of this now.

Handy Hint: Insert one of the 1/16" dia. M.W.

stabilizer pins provided, into this piece of tubing,

almost to the end and then flatten the tubing in a

vise. The music wire pin will keep the tubing round.

D 8. Now install the rudder drive tubing on the left

fuselage side. As shown, this tubing exits the

lower rear of the fuselage side through a heavily

angled hole that must be drilled. A sharpened

piece of tubing will work well for this step. Like the

elevator tubing, the rudder housing tube is glued in

place along the fuselage side at 1-1/2" intervals.

Use a razor blade and then your sanding block to

smooth the area of tubing exit on the outside of the

fuselage. Don't worry about the stab and rudder

tubing that is loose up front, we'll nail these down

later.

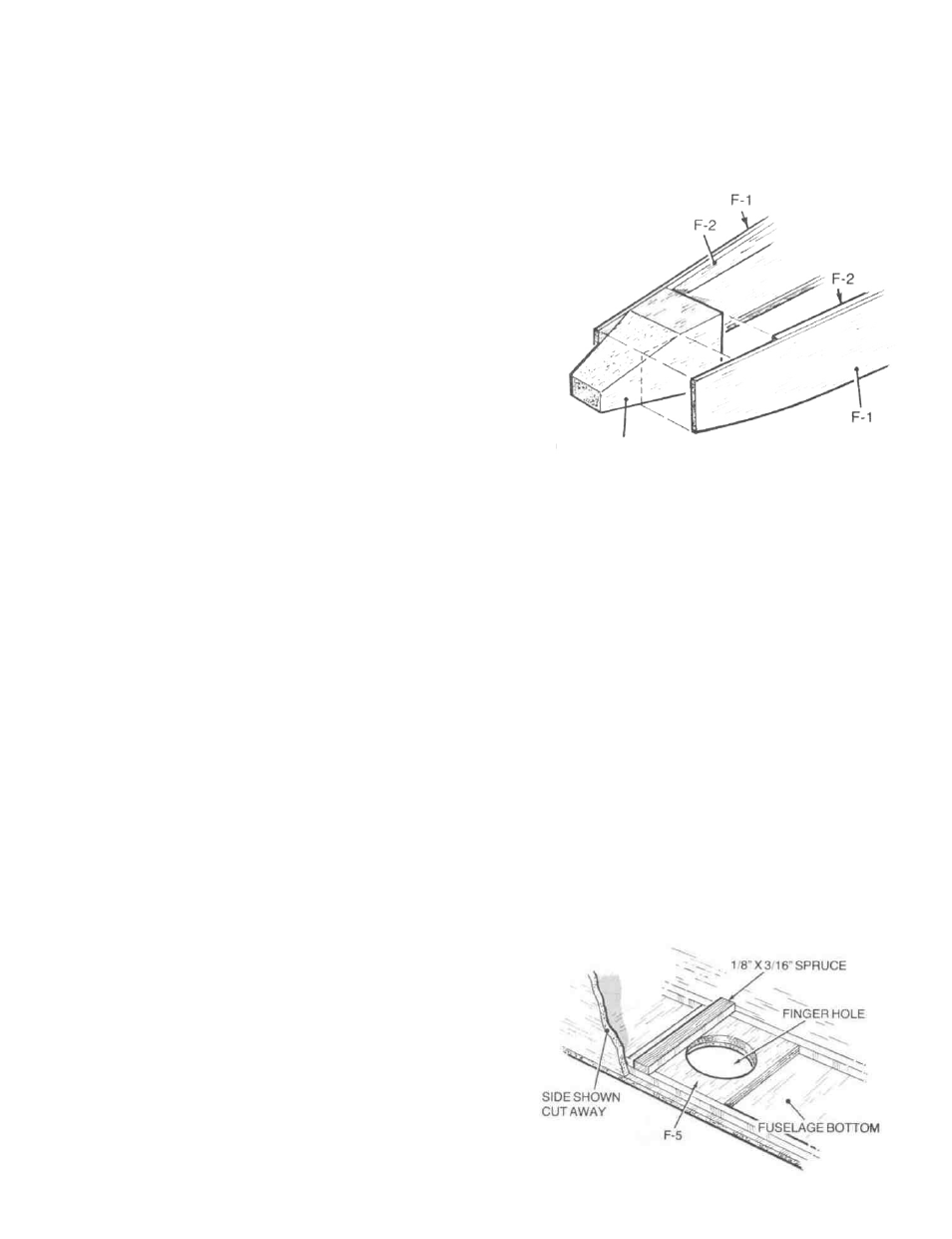

questions, take the time now to trim the ends of

the longerons and/or the F-2 doublers to correct

the problem. Once satisfied, glue the nose block in

place and clamp or tape the fuselage sides

together at the nose until dry. When it is, use your

sanding block again to smooth out the

fuselage/nose block fit, top and bottom.

NOSE BLOCK

D 9. Now glue the remaining T-1 fin side in place on the

left side of the fin, with the stab drive cable and fit-

ting in place. Glue 1/32 " 3/16"" caps on the left side of

the fin frame, just as you did on the right. Use your

sanding block to smooth this structure. Now trial-

fit the left fuselage side to the right, paying par-

ticular attention to the fit of the fin. This should be

accurate and close-fitting. Once satisfied, the left

fuselage side can be glued in place to the fin and

right side—the glue joints should be at the top and

bottom longerons 1/2" ahead of the fin's leading

edge back to and including the left T-1 fin side. Ac-

curately match the fuselage sides, weight and/or

pin this structure to your work surface and allow to

dry.

D 10. Ply fuselage former F-3 should now be trial-fitted

in place (just move the loose ends of the rudder

and stab tubes out of the way). Make sure this

former fits well, trim if necessary. Take one of the

servos that you plan to use and hold it in place on

the inside of the fuselage, about where it will be

mounted. Note the location for the two drive tubes

on F-3 (these should be lined-up with the servo's

output arm. Remove F-3 and either drill a hole or

slot the former to accept the two tubes. You now

can glue F-3 in position at the marks made earlier

on each of the fuselage sides. We suggest using

something like 5-minute epoxy for this operation

since you may need a moment or two for position-

ing. We also suggest that you accurately position

the entire structure over top view on the plans and

use weights or pins to ensure that the whole thing

is kept straight!

D 11. Trial-fit the balsa nose block in place and pinch the

fuselage sides together as if you were gluing it in

place. How does it fit? Everything square as it

ought to be? When viewing the structure head-on,

is it straight? If the answer is no to any of these

D 12. Locate the 1/8" ply wing-bolt plate from your parts

bag. Trial-fit this part in place at the location

shown on the plans (beneath the wing's trailing

edge). Trim if needed. Once satisified, glue this

plate in place against each fuselage side and up

against the bottom of the F-2 doublers. Locate and

remove the die-cut F-5 fingerhole reinforcement

piece. Trial-fit F-5 in place flush with the bottom

fuselage longerons and directly beneath the 1/8"

ply bolt plate just installed. Once satisfied with the

fit, glue F-5 in place, between the bottom

longerons and flush with the fuselage sides. Now

cut a 1-3/8" length of 1/16" x 3/16" spruce spar stock. As

shown on the plans, this part is now glued in place

on top of F-5, between the fuselage sides, at the

forward edge of the fingerhole cut-out. This part

serves to reinforce F-5 against undue wear during

repeated hand-launches. Lastly, cut and glue the

1/8" x 3/16" balsa cross brace in place. As shown on

the plans, this brace fits between the bottom

fuselage longerons, just behind the receiver loca-

tion. Use your sanding block to now lightly smooth

the fuselage bottom prior to sheeting.

7