Top Flite Wristcrat User Manual

Page 8

D 13. Remove ply die-cut part F-6 from its sheet. This is

the forward, bottom fuselage sheet which is

meant to fit from the cross brace just installed, for-

ward to the noseblock. Clean-up its edges with a

sanding block. F-6 can now be glued in place using

weights or tape to hold it (note that its rear edge is

glued halfway across the width of the cross brace;

use a scrap piece of balsa to clean out any oozing

glue from beneath this edge). Using the 1/16" x 3"

balsa sheet stock provided, finish sheeting the

fuselage bottom from the rear edge of F-6, aft to

the end of the fuselage - as shown this sheeting is

applied cross grained. Once the sheeting is in

place and dry, use your sanding block to smooth

all of the edges (balsa sheeting and F-6) flush with

the fuselage sides. Now clear out the finger hole

described by F-5, using sandpaper to smooth the

edges. The last thing you may wish to do on the

bottom of the fuselage is to drill a hole, back

toward the leading edge of the fin location, to pro-

vide an exit for your antenna. On our prototypes we

angled this hole forward and lined it with a short

length of plastic tubing.

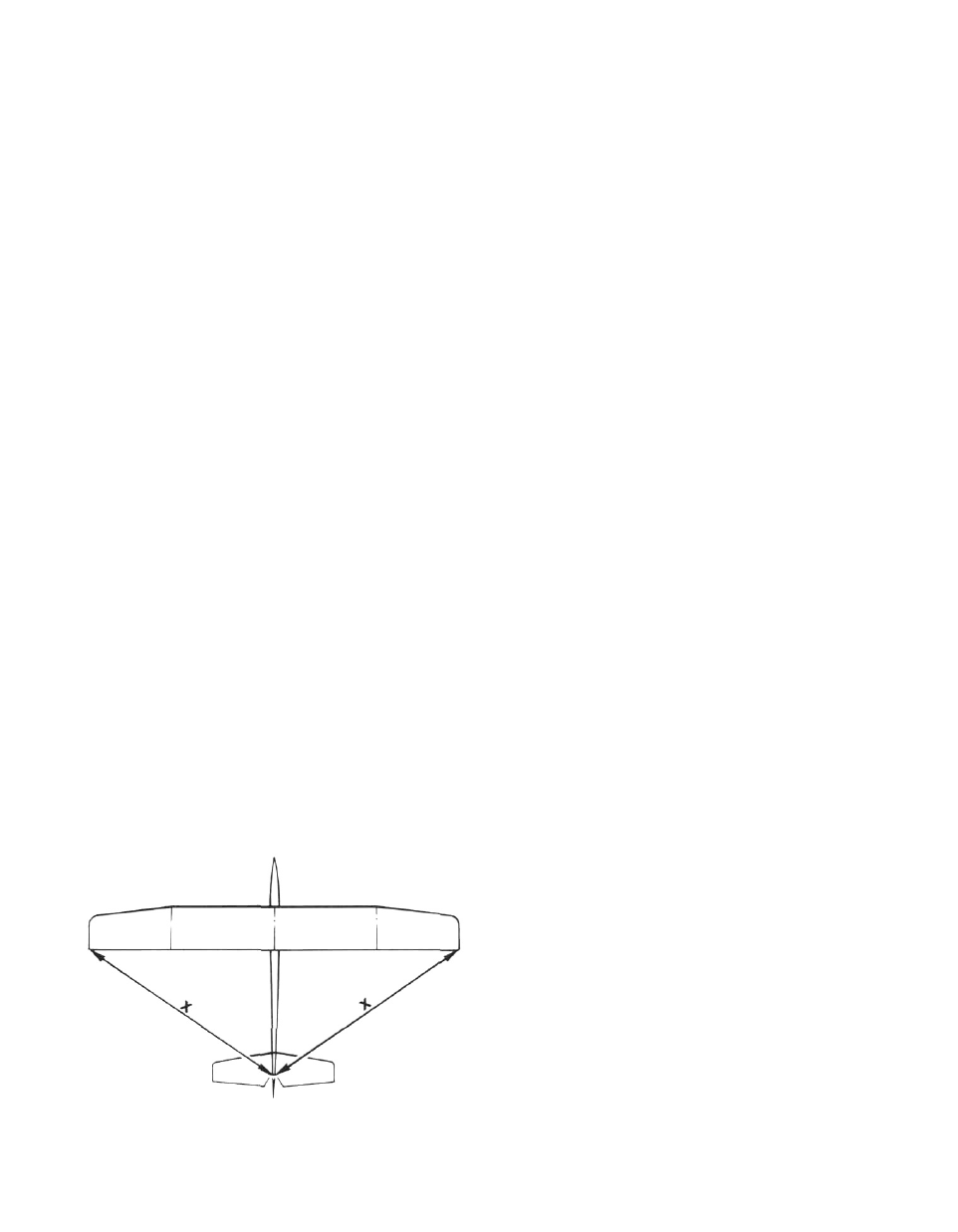

D 14. Now trial fit your wing to the fuselage. Make sure

the wing is centered and that the leading edge is

up against F-3. Holding these two structures

together, observe the fit between the bottom of the

wing and the wing saddle area. It may be

necessary to slightly bevel the tops of the fuselage

sides and F-2 doublers to get a snug fit; do this

now. Once you're satisfied with the wing/fuselage

fit, you're ready make the hold-down system.

Again place the wing on the fuselage and use

weights to hold it firmly in position. Make sure that

the wing is squarely in position on the fuselage by

taking wingtip-to-tailpost measurements as

shown in the diagram ("X" should equal "X").

Locate the 3/16" dia. dowel from the parts bag. A

3/16" dia. hole must now be drilled through F-3 (see

mark) and into the wing's center W-1 ribs, to a

depth of 1-7/16", measured from the front face of

F-3. Measure this depth on y o u r drill bit and note it

with a strip of tape. Once the hole is drilled, remove

DISTANCES "X" and "X"

MUST BE EQUAL

the wing from the fuselage and trial-fit the 3/16" dia.

dowel in place. Use sandpaper to slightly round

the front edge of the dowel. Now glue the dowel in

place in the wing (clean-off any oozing glue). Once

dry, again fit the wing to the fuselage and use

weights to hold it in place, as before. The rear

nylon bolt hold down system is now made. Start by

drilling a hole, with a #29 drill bit, through the

wing's trailing edge and through the 1/8" ply wing

bolt plate at a slightly forward angle (see plans).

Remove the wing from the fuselage. Enlarge the

hole in the wing's trailing edge to allow the 8-32

nylon bolt to slip through to the head. Now using

either an #8-32 tap or an 8-32 bolt (metal), tap the

threads into the hole made in the ply wing bolt

plate. Once the threads have been cut we suggest

giving them a very thin coat of instant CA glue and

again running the tap through them. This

toughens the threads in the plywood. Re-fit the

wing to the fuselage and bolt it in place to again

check the fit. Note that about 7/8" of the length of

the nylon bolt (1-1/2" supplied) can be trimmed off.

Remove the wing from the fuselage.

D 15. Use a flat sanding block and light sandpaper to

carefully sand the top of the fuselage, from F-3 for-

ward across the top of the noseblock. Use care

here as we want the forward hatch to fit nicely.

From your parts, locate and remove the 3/8" x 2" x

10" length of balsa. Again using your sanding

block, bevel-sand one end of this block to fit

perfectly against the forward face of F-3 when held

in place on top of the fuselage. As shown on the

plans, the forward end of the radio hatch is now cut

at the angle shown. Once the bevel cut has been

made, use the sanding block to lightly clean-up

each end of the cut, set aside the hatch part for a

moment. On the remaining length of block,

measure about 1-3/4" forward from the bevel cut

and cut this piece off. This piece then becomes the

forward "lip" for the radio hatch. Use tape to hold

the radio hatch in place to the top of the fuselage,

against F-3. Apply a small amount of glue to the

bottom of the forward block and glue it in place to

the top of the fuselage and noseblock, matching

the bevel on the front of the radio hatch block, thus

ensuring a nice fit between these two blocks. Un-

tape and remove the radio hatch block. Locate and

remove the ply F-4 hatch "lip" from its die-cut

sheet. F-4 can now be glued to the forward, bottom

surface of the hatch block with 3/16" of its forward

end protruding, thus providing a fit beneath the

forward block just installed and preventing shif-

ting from side-to-side. As shown on the plans, the

rear face of the radio hatch block will need a slight

amount of routing out to allow the wing's hold-

down dowel to clear; do this now. Once satisfied

use a couple drops of glue to l i g h t l y tack-glue the

radio hatch in place for shaping.

D 16. Remember that V length of 1/16" I.D. aluminum

tubing that you were asked to save back when you

built your stabs? Locate it now, we're going to use

it. With a 3/32" drill bit, finish the hole through the fin

(the stab pivot hole). Cut a 1/4" length of aluminum

8