Top Flite Wristcrat User Manual

Page 5

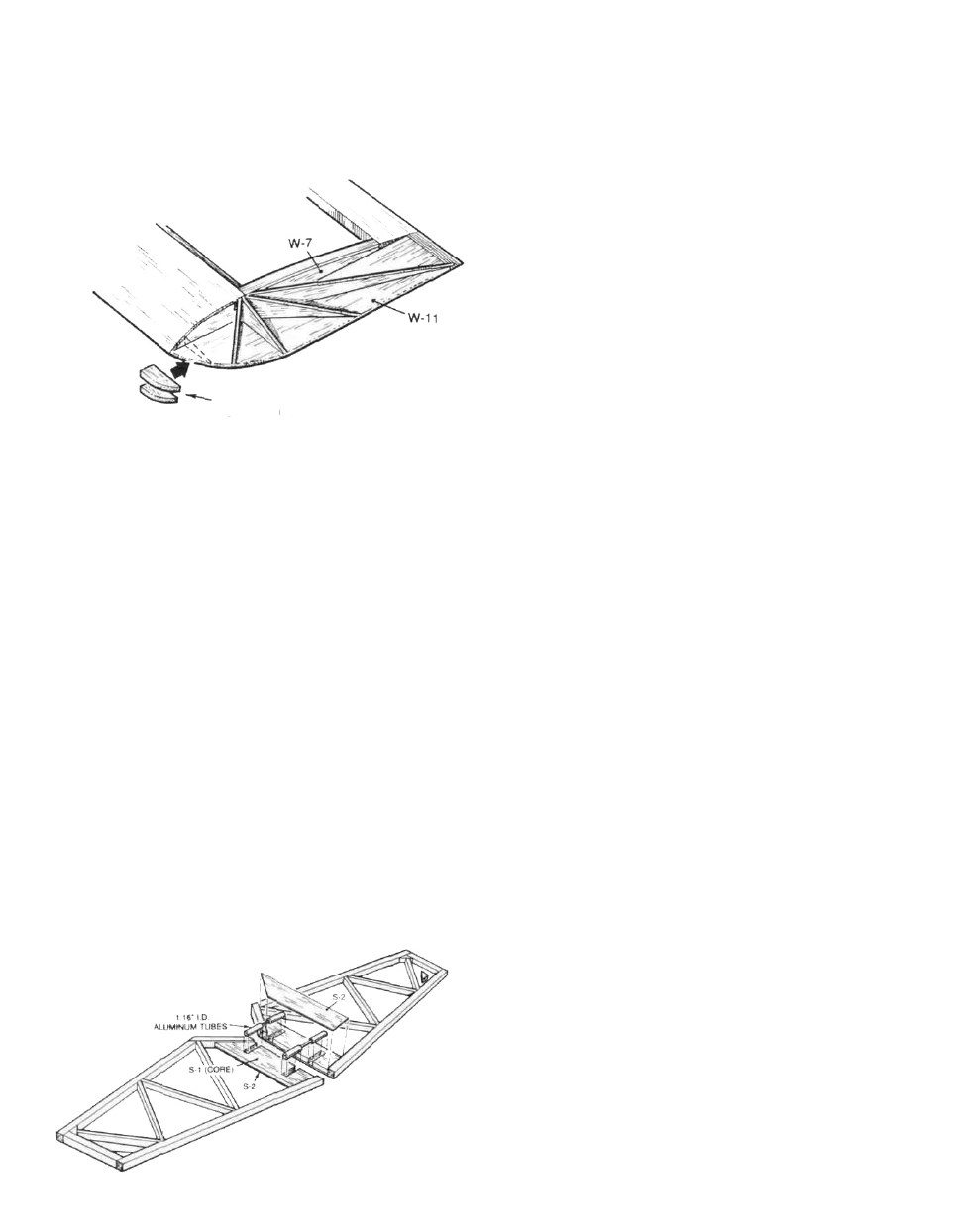

leading edge of the wingtip and glue these in

place. From the remaining 1/16" balsa sheet provid-

ed in your kit, cut, fit and glue in place the wing tip

braces as shown on the plans. You may elect to

add these only to the top, which will work.

However, on our prototypes we added these

braces top and bottom and have yet to break a tip.

.1/8" BALSA FILL

TOP AND BOTTOM

The completed wing structure should now be carefully

sanded to final shape including the leading edges. Make

every attempt to render the wing as smooth and as

uniform as possible.

Ply die-cut part F-12, wing bolt reinforcement, can now

be glued in place on the wing's center section at the trail-

ing edge, as shown. With the exception of the front and

rear fuselage/wing fairings, the wing should now be

complete.

STABILIZERS/RUDDER CONSTRUCTION

STABILIZERS

D 1. Remove the four 1/32" S-2's and both of the 3/32" S-1's

from their respective die-cut sheets. These are

the stab cores (S-1's) and stab core caps (S-2's).

From your parts bag, locate the single 3" length of

1/16" I.D. aluminum tubing. Measure and cut-off

two, 1-1/4" lengths of this tubing. Use a single edge

razor blade and a rolling motion on a hard surface

to do this. Save the remaining 1/2" length. Note the

cross-grain marks in the S-1 cores, these are the

locations for two lengths of aluminum tubing that

you just cut. Use a straight edge and a sharp #11

blade to clear-out a 3/32" slot at these marks to

allow the nesting of the two pieces of tubing. Take

care in cutting these slots to maintain their

parallelism.

D 2. Glue t w o o f t h e S - 2 c a p s t o t h e b o t t o m o f e a c h S - 1 ,

carefully lining-up their edges one to the other.

Use sandpaper to lightly rough-up the two 1-1/4"

lengths of aluminum tubing. Place the two S-1/S-2

structures together on your building board with

their inboard edges touching and the slots lined

up. Glue the two lengths of aluminum tubing in

place in the slots being careful to keep glue out of

the tube ends. Wipe off any excess glue that may

ooze up. Now glue the two remaining S-2 parts to

the tops of the S-1's, aligning their edges, weight

to keep these flat and allow to dry. If you're using

Pacer Slo-Zap, this will be very fast. Cut the two

structures apart, at the center, using a sharp razor

blade or a fine-toothed X-acto-type saw. Clean-up

the ends of the aluminum tubing with your #11

blade. Holding the two structures together, one

on top of the other, use your sanding block to

sand each of the edges flat.

D 3. Locate the two 1/16" dia. x1-1/2" steel pins from your

parts bag. Clean the ends of each of these with a

grinder or carbide cut-off wheel and trial-fit them

into the aluminum tube nests in each of the stab

core assemblies. You should be able to lay this

joined assembly directly over the stab plans and

they should match accurately. Trim as needed to

achieve this. Once satisfied, weight or pin the

wire-joined core assemblies in place over your

plans (protect the plans with a piece of Monokote

backing) and build the balance of each stab half

onto each stab core assembly using the 3/16" sq.

and 3/32" x3/16" balsa stock provided.

D 4. Once the stab halves are finished, remove them

from your work surface and use your sanding

block to first sand the top and bottom surfaces of

each flat and then to carefully "airfoil" them to

the cross-sections shown on the plans. Use care

to not sand these structures to thin, we don't

want them weak. Set these assemblies aside for

now.

RUDDER

D 1. The rudder is built directly over the plans, using

the 3/16" sq. and 3/32" x 3/16" balsa stock provided, just

as the stab halves were.

D 2. Remove the completed rudder from your work

surface and use your sanding block to smooth

the sides as well as the edges. As shown on the

plans, the top, leading edge and bottom of the

rudder, on each side, is capped with 1/32" x V

balsa strips, cut from the RC-35-5 die-cut sheet.

This renders the rudder the same thickness as the

fin.

The final sanding of the rudder and the beveling of its

leading edge, for hinging purposes, will be done later in

Final Assembly.

FUSELAGE/FIN CONSTRUCTION

Note that the fuselage and fin, with it's stabilizer drive,

are constructed in the following set of instructions, as a

finished, single unit.

5