Installing monokote hinges – Top Flite Wristcrat User Manual

Page 11

Cover these structures just as you normally would; bot-

tom first, followed by the tops (in the case of the stab

halves). But do not shrink the covering yet. Make sure all

of the outer framework of these pieces is adhered to with

the Monokote. Next, cut a couple of 7" - 9" lengths of

straight, stiff spruce stock; something like1/8"x1/4" will do

nicely. Using three office-type paper clamps, mount and

clamp one length of spruce on each side of the trailing

edge of the piece you're working on. The spruce won't

hurt the structure and the clamps ensure that the trailing

edge will retain it's shape. Now use your Top Flite heat

gun or iron to shrink the covering equally on both sides

(be sure the vent holes are cleared out). Let the structure

cool and then remove the clamps and spruce. You

should find that everything did indeed stay straight.

Lastly, clear out all of the required holes; rudder drive

tube, rudder horn slot, stab drive and pivot holes, etc.

Note that we've not indicated any kind of hold down

method for the radio hatch block. On our prototypes this

was not necessary because of the closeness of the fit

after covering. If yours does not fit that well, a little piece

of tape is all that's needed.

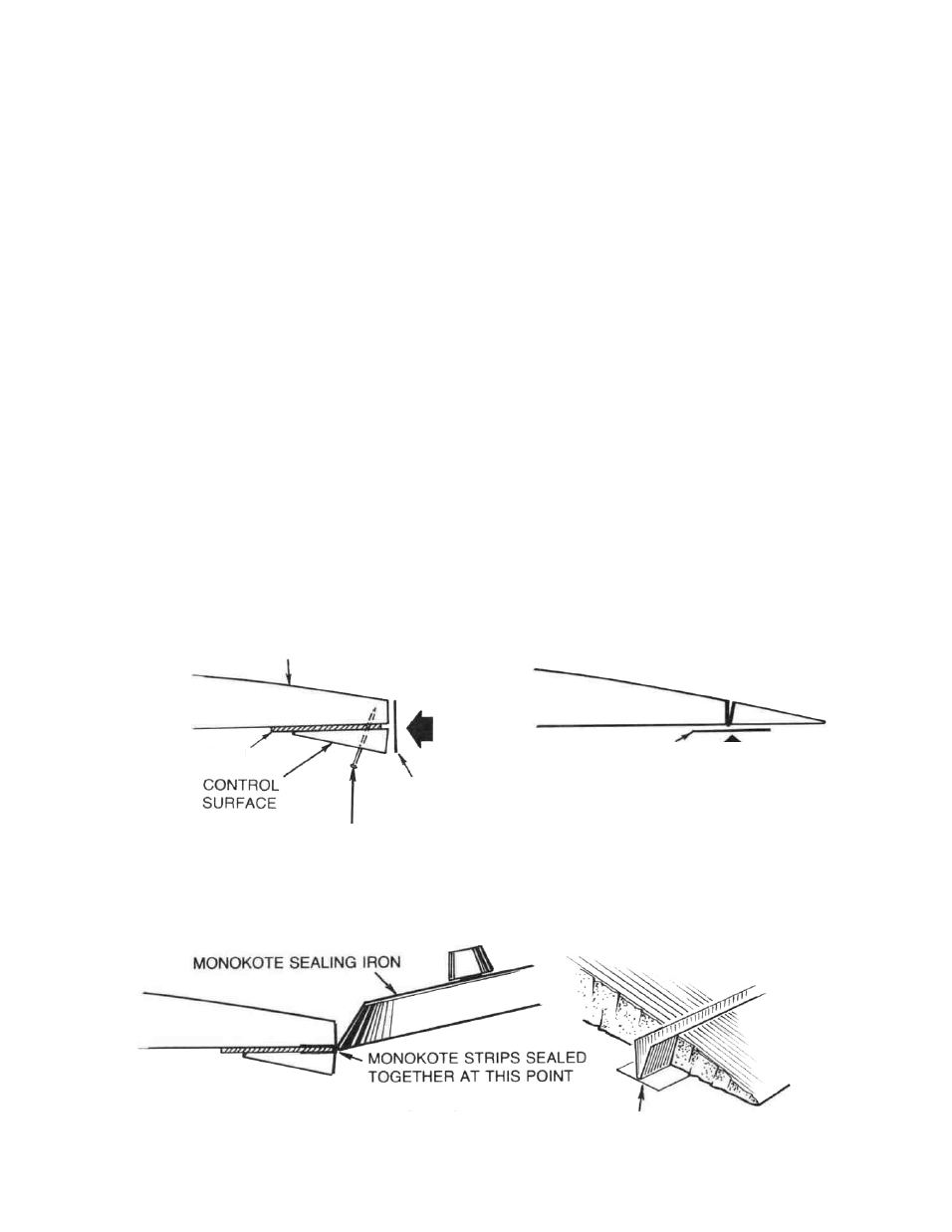

In the interest of aerodynamic efficiency, light weight

and simplicity, we strongly suggest that you hinge your

rudder (and flaps, if you have them) with Monokote as

shown in the drawings provided.

RADIO INSTALLATION

Before installing your servos, make sure that they run in

the right directions. If you have servo reversing capabili-

ty, this is a simple task. Install the servos in the fuselage

on the rails provided earlier.

From your parts bag, locate the 1-1/2" length of .038 I.D.

brass tubing. This material will be cut up to provide

solder connections between the drive cables and the

soft wire paper clip connectors. We recommend the use

of a good quality flux and solder when perform ing the re-

quired solder joints; Harris's Stay-Clean Flux and silver

solder are great products for this operation.

Drill a 1/32" dia. hole through the rudder horn to accept the

paper clip drive wire. Cut off about 1/4" of the brass tubing

connector material and clean out each of it with your #11

blade to accept the cable and paper clip ends. Cut off the

required length of paper clip wire (see plans) to make the

connection to the rudder horn and bend one end into a

"Z" bend. Slip the brass connector halfway onto the

drive cable end and the paper clip wire into the other end

of this connector. Sweat solder the three pieces

together, using a minimum of solder. Slip the opposite

end of this drive cable into the rudder tube and feed it's

length through the fuselage and into the servo compart-

ment — don't cut off the excess cable yet. Attach the

rudder horn to the "Z" bend and carefully glue the horn

into the slot previously provided.

INSTALLING MONOKOTE HINGES

WING, FIN, ETC.

PIN THROUGH CONTROL

SURFACE TO PREVENT

MOVEMENT

1/32" SHIM

MONOKOTE

MONOKOTE IRONED TO

INSIDE FACES

IRON SECOND MONOKOTE STRIP

TO OUTSIDE FACE

MONOKOTE HINGE

11

SEAL MONOKOTE STRIPS

TOGETHER. KEEP SHIM PRESSED

AGAINST SEAM AS BACK UP

WHILE SEALING.