Top Flite TOPA0290 User Manual

Page 33

❏

5.

If b

uilding w

o

rking flaps

, mount the flap ser

v

o

s

to tw

o more sets of mounting b

loc

ks

.

Note that while

the aileron ser

v

os are mounted to the hatches in a

“mirrored”

image

, the flap ser

v

os are

not

mirrored

(so that the flaps will w

o

rk

together (instead of in

opposition as do the ailerons).

It will be easier to hook up the ailer

ons bef

ore

joining the wing halves,

so go ahead and do so

as instructed belo

w

.

But it will be better to hook

up the flaps after the model has been co

vered

and the flaps ha

ve been permanentl

y joined to

the wing with the hing

es.

❏

6.

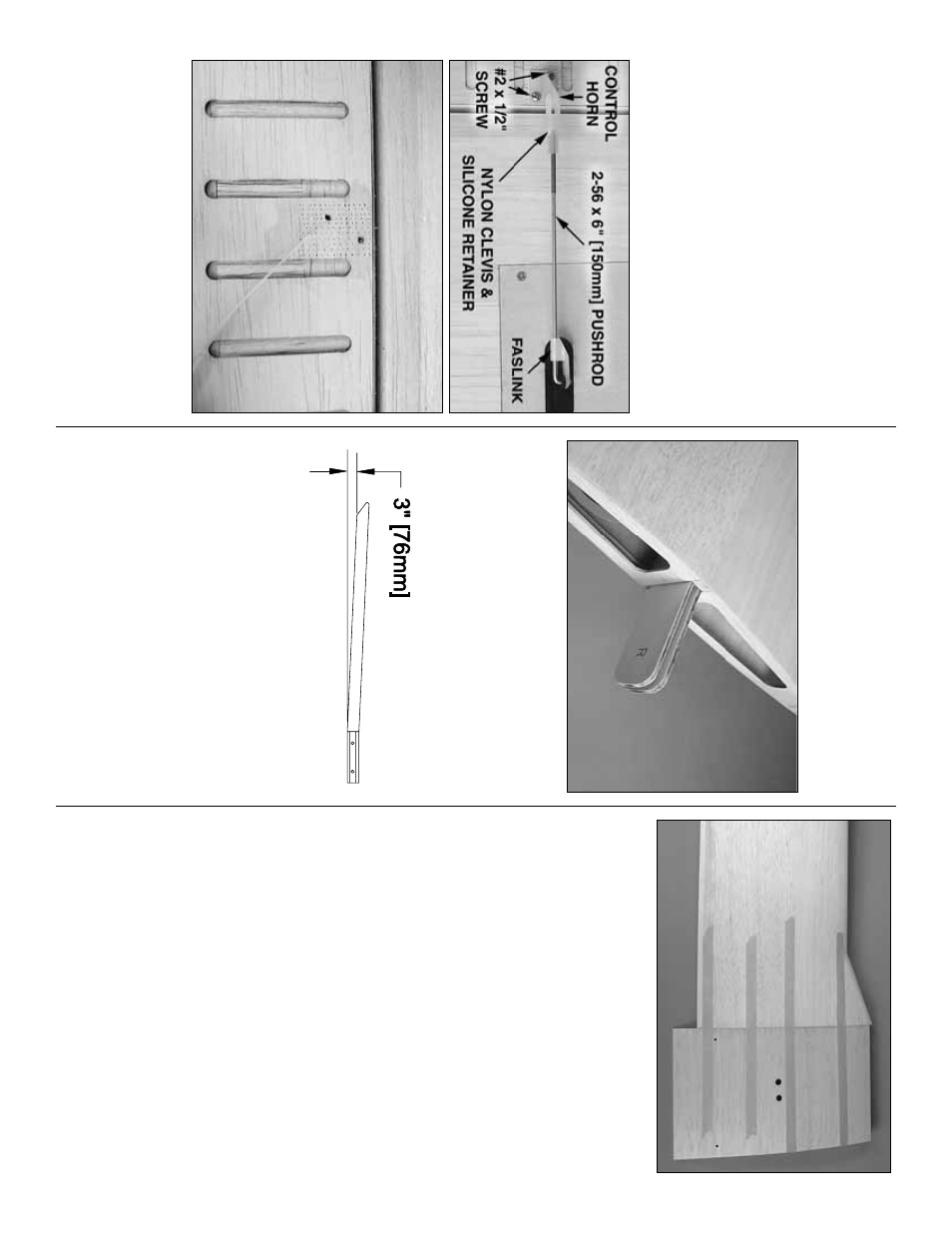

Enlarge the holes in the aileron ser

vo

ar

ms with a

Hob

bico Ser

vo

Hor

n Dr

ill (HCAR0698) or a 5/64" [2mm]

dr

ill.

Connect the ailerons to the ser

vos using the

hardw

are sho

wn in the photo

.

D

rill 1/16" [1.6mm] holes

into the ailerons f

or the scre

ws that mount the hor

ns

.

P

o

ke

se

ve

ral pinholes into the ailerons and w

et the area

with a f

e

w drops of thin CA to harden the balsa.

JOIN THE

WINGS

❏

1.

Remo

v

e

the flaps and ailerons from both

wing panels

.

❏

2.

T

est fit the die-cut 1/8" [3.2mm] plyw

ood

wing

joiner

s

into each of the three wing panels

.Note that the

ends of the joiners mar

ked

“R”

are the ends that go into

the center panel.

Mak

e adjustments as necessar

y to

get the joiners to fit into the wing panels

, then test fit the

wing panels together with the joiners

.

❏

3.

Tightly tape the outer panels to the center

panel.

There should be no gaps

.

Chec

k the dihedr

al

b

y

la

ying the center panel flat and measur

ing the

distance betw

een the w

o

rkbench and the bottom of

the tips under the spar

.

The distance should be 3"

[76mm], b

ut a v

a

riance of plus or min

us 3/8" [10mm]

is acceptab

le

as long as both panels are the same

.

❏

4.

Prepare f

o

r gluing the panels together—this

should be done one panel at a time

.Gather all the items

necessar

y including 30-min

ute (or longer) epo

xy

,

mixing utensils

, w

ax paper

, masking tape

, paper to

w

e

l

squares and denatured alcohol f

o

r clean

up

.

❏

5.

Mak

e

sure an

y par

ts-fit prob

lems in joining the

wings ha

v

e

been resolv

ed—there w

on’t be time to

correct prob

lems once y

ou star

t gluing.

Mix a batch

of 30-min

ute epo

xy—1/2 oz.

[15cc] should be more

than enough to do the job

.

Apply epo

xy to the r

ib on

the end of the outer panel and to the inside of the

outer panel where the joiners go

.

Apply epo

xy to the

joiners and inser

t them into the outer panel.

Coat the

inside and outside of the outer panel the same w

a

y,

then slide the tw

o together

.W

ipe a

w

a

y

e

xcess epo

xy

as it ooz

es out.

Use plenty of masking tape on the

top and bottom of the wing to

tightl

y

hold the panels

together

.

Contin

ue to wipe a

w

a

y

e

xcess epo

xy as

y

ou mak

e sure the panels are accur

ately aligned.

Do

not disturb the wing until the epo

xy has fully

hardened.

Hint:

It will be m

uch easier to wipe e

xcess

epo

xy from the wing bef

ore it has hardened than it

will be to tr

y sanding if off after it has hardened.

❏

6.

After the epo

xy from the pre

vious step has

hardened remo

v

e the masking tape and join the

other panel to the assemb

ly

.

❏

7.

If y

ou ha

v

en’t y

et done so

, fill the corr

ugations

with lightw

eight balsa filler

, allo

w to dr

y,

then

lightly sand smooth.

Set the wing in a saf

e place while y

ou are w

o

rking on

the fuselage

.

- 33

-