Top Flite TOPA0290 User Manual

Page 22

❏❏

12.

Remo

v

e

the top spar from the assemb

ly

.

Apply a bead of medium or thic

k CA along the top

edge of the spar w

e

b

, then reposition the top spar

.

Mak

e

sure

W2 is still at the correct angle using the

dihedr

al gauge

.

❏❏

13.

Glue the die-cut 1/8" [3.2mm] balsa

inner

sub leading edg

e

into position.

❏❏

14.

Prepare the top of the wing f

or sheeting b

y

tr

imming and sanding the sub leading edges

, the

aileron ba

y sub tr

ailing edge

, the flap ba

y tr

ailing

edge and the top spar e

v

en with the tops of the r

ibs

.

❏❏

15.

T

rim one of the aft skins to fit the wing so

that the front edge aligns with the

mid

dle

of the top

spar and the aft edge aligns with the middle of the

flap ba

y sub tr

ailing edge

.

The skin should e

xtend

1/16" [1.6mm] or so past the aileron ba

y sub tr

ailing

edge to allo

w f

or tr

imming later

.

❏❏

16.

Glue the aft skin into position.

Aliphatic resin is

recommended as it will allo

w time f

o

r positioning.

Use

w

e

ights and

T-pins to hold the skin in position while the

glue dr

ies

.The rest of the tr

ailing edge betw

een the

W9

ribs at the wing tip will be sheeted later

.

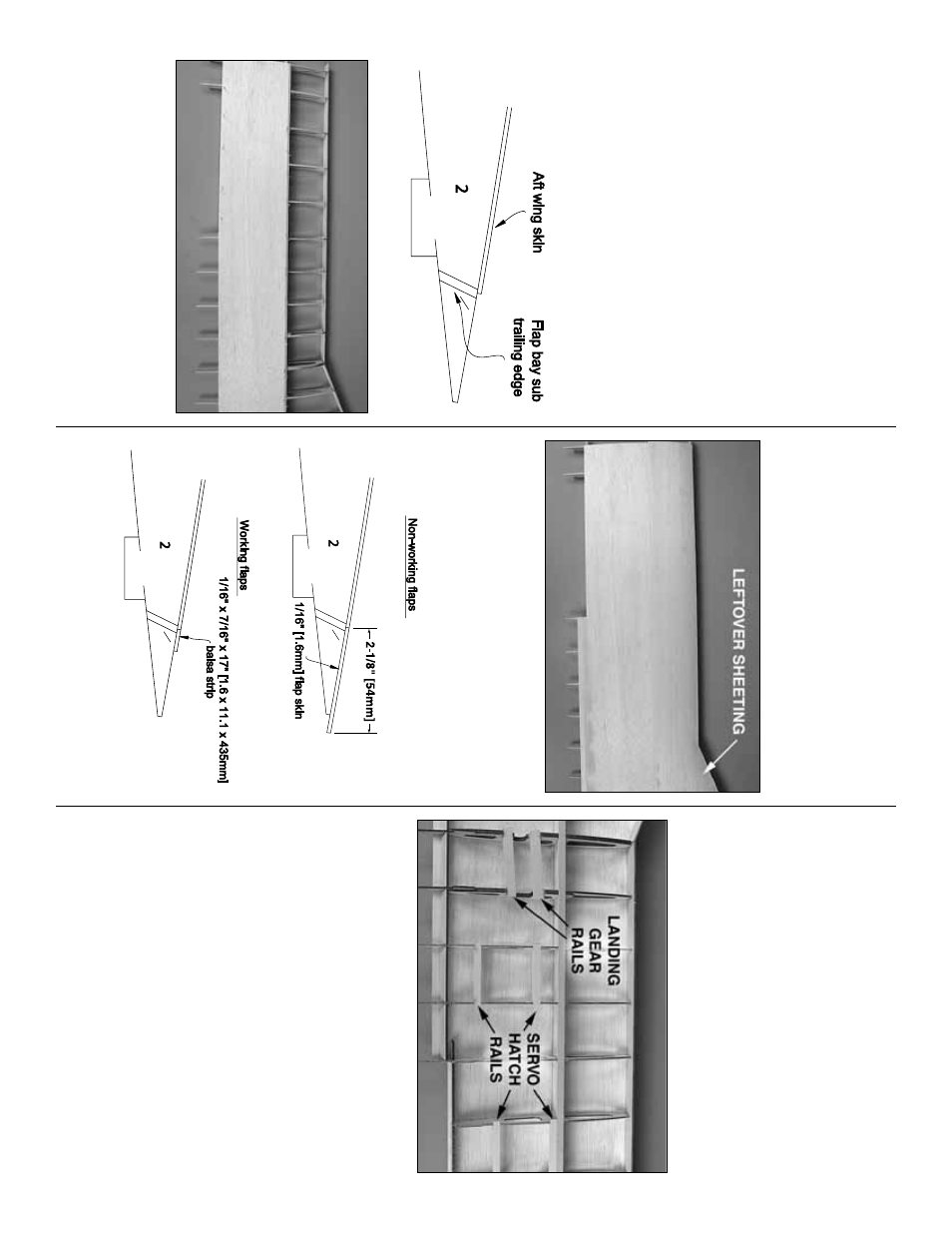

Ref

er to this photo f

or the f

ollo

wing tw

o steps.

❏❏

17.

Cut and tr

im one of the f

orw

ard skins to fit

the wing, then glue it into position.

Use a piece of

lefto

v

er sheeting f

or the small cor

ner at the leading

edge where the front sheet w

on’t reach.

Use w

eights

and/or

T

-pins to hold the sheeting do

wn while the

glue dr

ies

.

❏❏

18.

If

not

b

uilding flaps

, test fit one of the die-cut

1/16" [1.6mm] balsa

flap skins

to the wing.

The tr

ailing

edge of the skin should e

xtend 2-1/8" [54mm] aft of the

top wing skin.

Cut out the slots f

or the corr

ugations and

tr

im the flap skin as necessar

y f

or a good fit, then glue

the skin into position.

If y

ou

are

b

uilding w

o

rking flaps

,

tr

im a 7/16" x 17-3/4" [11 x 435mm] str

ip from a piece

of lefto

ver 1/16" [1.6mm] hard balsa.

Glue the str

ip o

ver

the flap ba

y tr

ailing edge

.

❏❏

19.

After the glue on all of the wing sheeting has

dr

ied, remo

v

e

the wing from the b

uilding board.

Ref

er to this photo f

or the f

ollo

wing tw

o steps.

❏❏

20.

Flip the wing o

v

er and la

y it on y

our

w

o

rkbench.

Cut tw

o 3-3/4" [95mm] long

landing

g

ear rails

from the 1/4" x 1/2" x 16" [6.4 x 13 x

410mm] bass

w

ood stic

k.

Use 30-min

ute epo

xy to

glue the r

ails into position.

F

or additional strength,

milled glass fibers could be added to the mixture

.

This will allo

w y

ou to b

uild up small fillets without the

glue dr

ipping a

w

a

y

from the joints

.

❏❏

21.

While the epo

xy on the landing gear r

ails is

hardening, mak

e the

ser

v

o

hatc

h rails

from a 1/4" x

3/8" x 36" [6.4 x 9.5 x 910mm] bass

w

ood stic

k and glue

them into position.

Be cer

tain to glue the aileron hatch

rails in the tw

o inboard

W8 r

ibs as sho

wn on the plan.

Note:

If not b

uilding w

o

rking flaps

, there is no need to

cut and glue in the ser

vo

r

ails f

or the flaps

.

❏

22.

Retur

n to step 4 and b

uild the r

ight wing panel.

Don't f

o

rget to b

uild o

v

er the

right

wing plan.

- 22

-